End cover box for horizontal centrifugal casting of roll

A technology of centrifugal casting and end caps, which is applied in the field of end cap boxes, can solve the problems of poor quality stability of the refractory cement layer, easy slag inclusion in the inner and outer bonding layers, and uneven thickness of the outer layer of the casting blank, so as to shorten the use preparation period and reduce the The effect of drying energy consumption and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

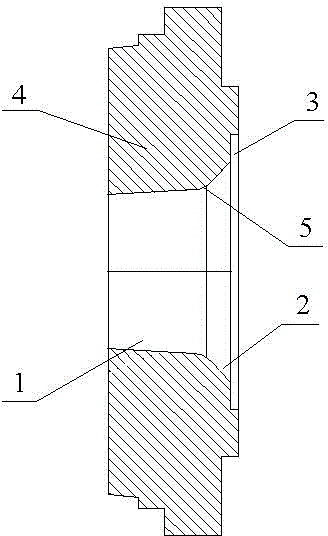

[0018] In the present invention, the metal-shaped end cover box is made of carbon steel, and the end cover box 4 is provided with a through hole for pouring molten iron along the central axis. The structure is as figure 1 Shown. The through hole is a horn-like three-step stepped hole, the first stepped hole and the second stepped hole are both conical, the taper angle of the first stepped hole 1 is 10°, and the taper angle of the second stepped hole 2 is 120 °, the third stepped hole 3 is a straight hole, the first stepped hole 1 and the second stepped hole 2 are transitionally connected by a round corner 5, and the radius of the round corner 5 is 10 mm. The inner surface of the through hole of the end cover box 4 is provided with a thread, the depth of the thread is 5mm, and the width is 3mm.

[0019] Before the end cover box 4 is used, the inner surface of the through hole of the end cover box 4 is coated with a certain thickness of refractory cement. Other types of refractory...

Embodiment 2

[0022] The structure of the end cover box 4 in this embodiment is basically the same as that of Embodiment 1, with the difference that: the taper angle of the first stepped hole is 20°; the taper angle of the second stepped hole is 100°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com