Low-cost steel-making process for manufacturing flaw detection plate

A low-cost and technological technology, applied in the field of low-cost steelmaking technology, can solve the problems of difficult production organization, affecting delivery time, long production cycle, etc., to shorten the production organization and preparation cycle, easy to operate, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through embodiment.

[0017] This embodiment is to produce 28mm Q345B flaw detection plate.

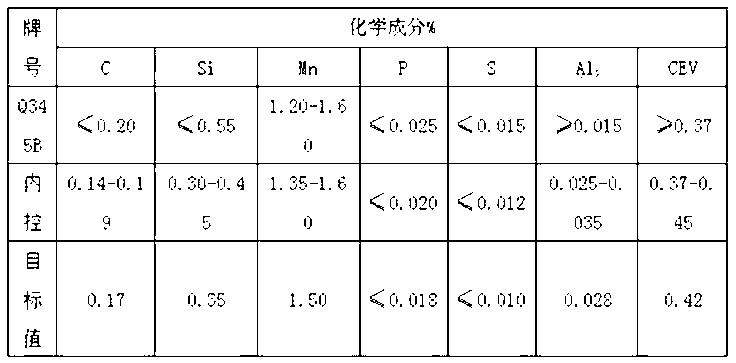

[0018] The composition of Q345B flaw detection plate is shown in the table below

[0019]

[0020] The specific process steps of the present embodiment:

[0021] ① The end point of the converter is controlled at 1660°C-1675°C, the end point target: [C]=0.06-0.10%, [P]≤0.015%, [S]≤0.030%, low temperature tapping, the oxygen content in the end point steel is less than 600ppm;

[0022] ② Add 150 kg of slag washing material after the furnace, and add 1.25 kg of slag washing material per ton of steel;

[0023] ③The aluminum content in the steel is controlled at 300ppm at LF outbound; the sulfur content in the steel is reduced to 75ppm in the LF process, the refining time is not less than 35 minutes, and the net argon blowing time after calcium treatment is not less than 5 minutes, and the liquid surface of the molten steel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com