Method and apparatus for turbine blades milling with once clamping

A steam turbine blade, one-off technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of long technical preparation and processing cycle, difficult alignment and alignment, high blade processing cost, and shorten the time Effects of technical preparation and production cycle, improved machining accuracy and product quality, short programming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Now take the processing of moving blades of X300A202001A-005A (1-5 stages of medium pressure cylinder) as an example to illustrate the present invention.

[0053] The first step to process a qualified blade is to establish an accurate blade model. According to the modeling requirements of the other steel rough moving blades in Turbsoft software, it is divided into the following parts and uses different software to complete its modeling work: blade body profile, blade root platform, blade crown platform and blank size setting. Since Turbsoft software has no surface modeling function, the primary modeling of the airfoil surface must be completed with MasterCAM software, and the secondary modeling of the airfoil surface and the setting of the blade root platform, blade crown platform and blank size are completed in Turbsoft software.

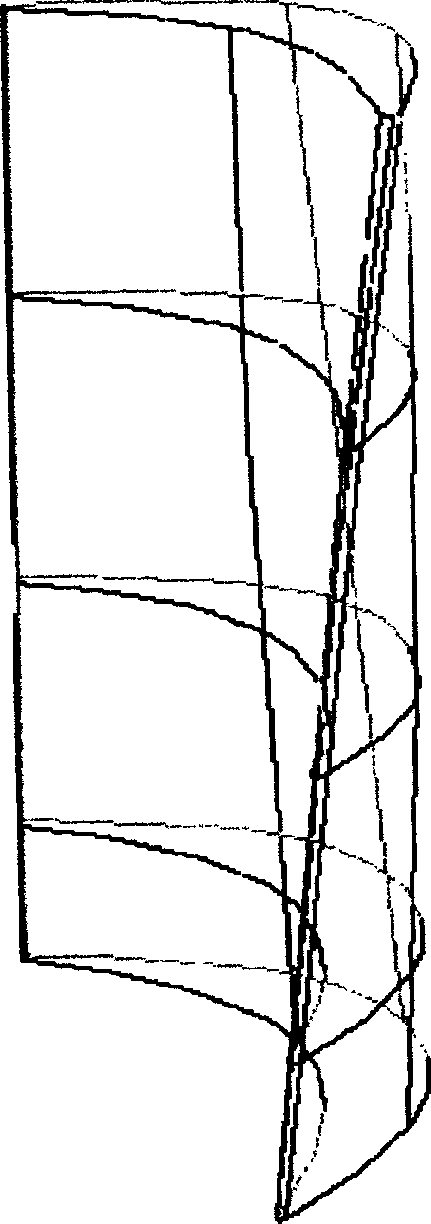

[0054] see figure 1 : One-time modeling of blade body profile, first input the discrete points of each section provided by the profile dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com