Process for machining flame cylinder floating wall tile blocks by adopting annular forgings

A process method and technology of ring forgings, which are applied in the field of aero-engines and gas turbines, can solve the problems affecting the overall performance of engines or gas turbines, metallurgical defects of floating wall tile castings, and low pass rate, so as to shorten the material preparation cycle and reduce the preparation cycle , The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

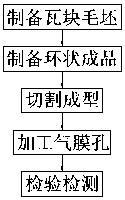

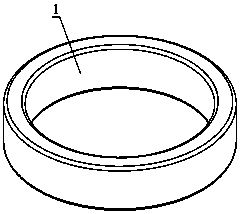

[0040] as attached Figure 1-7 As shown, a process method for processing the floating wall tiles of the flame cylinder by using ring forgings, including the steps of preparing ring-shaped finished products and cutting and forming steps, the preparation of ring-shaped finished products: machining the tile blanks to obtain ring The finished product, the size of the ring-shaped finished product is the same as the size of the cylindrical structure formed by the end-to-end connection of several tiles, and the cutting and forming is to cut the ring-shaped finished product to obtain several independent initial finished tiles.

[0041] In this embodiment, a process method for processing the floating wall tiles of the flame cylinder by using ring forgings, the floating wall tiles are prepared by first preparing the ring-shaped finished product, and then cutting the processing method, so that multiple floating wall tiles can be prepared in one process. The wall tile replaces the existin...

Embodiment 2

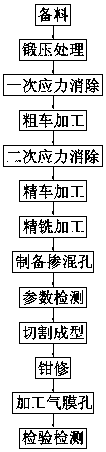

[0043] Such as Figure 1-7 As shown, a process method of processing the floating wall tile of the flame cylinder by using a ring forging in this embodiment is further refined on the basis of Example 1: it also includes step 1: preparing the blank of the tile: forging the blank to obtain tile blank, the tile blank is cylindrical, and the average diameter of the tile blank is the same as the average diameter of the finished tile; step 4: processing air film holes: prepare a number of channels on each initial finished tile The hole is used as the air film hole for guiding the cold air to make the finished tile; step 5: inspection and testing: inspect the processing size, roughness and cleanliness of the finished tile made in step 4 according to the requirements of the floating wall product, if the inspection result If the product does not meet the product requirements, corresponding treatment is carried out; the step of preparing a ring-shaped finished product is step 2, and the ...

Embodiment 3

[0052] Such as Figure 1-7 As shown, on the basis of Example 2, a process for processing the floating wall tiles of the flame tube by using a ring forging in this embodiment is further refined as follows: Step 2 specifically includes the following steps: Step 2.1: Rough turning: The inner circle, outer circle and both ends of the rough turning blank; Step 2.2: Finish turning: the inner circle, both ends and outer circle of the rough turning rough; Step 2.3: Finish milling: milling of the rough blank The outer circular surface is milled to form a raised part on the surface of the tile, and the raised part includes a connecting stud and / or a positioning post and / or a reinforcing rib; step 2.4: preparing a blending hole: the blank after processing in step 2.3 Prepare mixing holes for auxiliary fuel and air mixed combustion to obtain a ring-shaped finished product.

[0053]In this embodiment, a process method for processing the floating wall tiles of the flame tube by using the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com