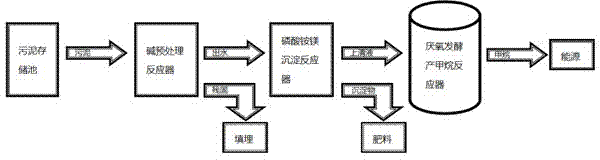

Method for processing residual sludge with integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on magnesium ammonium phosphate method and methane production based on anaerobic digestion

A technology of excess sludge and magnesium ammonium phosphate, applied in chemical instruments and methods, sludge treatment, sludge treatment, etc., can solve the problems of high pH value and discomfort subsequent treatment, and achieve the saving of chemical consumption, stable gas production process, The effect of promoting the methanogenesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) The remaining sludge in the urban sewage treatment system is concentrated or diluted by gravity to a concentration of 20 g / L, which is equivalent to a water content of 98%.

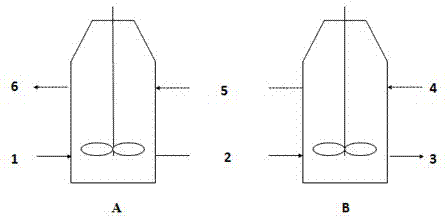

[0041] (2) if figure 2 As shown, in the first-stage alkaline hydrolysis reactor A, inject X volume of pretreated excess sludge 1, its concentration is 20 g / L, which is equivalent to a water content of 98%, stir at 150rpm, and perform alkaline hydrolysis for 1 hour to make The pH is controlled at 8.5-10.0. Then centrifuge to discharge the supernatant, that is, the first-stage alkaline hydrolysis effluent 6, and discharge the system; the residue after centrifugation, that is, the first-stage alkaline hydrolysis residue 2, is injected into the second-stage alkaline hydrolysis reactor. In the second-stage alkaline hydrolysis reactor B, inject 3 / 7X volume of water, adjust the pH to 13.0 with 10M sodium hydroxide solution while stirring at 150rpm, continue the alkaline hydrolysis reaction for 1h, a...

Embodiment 2

[0046] (1) The remaining sludge in the urban sewage treatment system is concentrated or diluted by gravity to a concentration of 20 g / L, which is equivalent to a water content of 98%.

[0047] (2) if figure 2 As shown, in the first-stage alkaline hydrolysis reactor A, inject X volume of pretreated excess sludge 1, its concentration is 20 g / L, which is equivalent to a water content of 98%, stir at 150rpm, and perform alkaline hydrolysis for 1 hour to make The pH is controlled at 8.5-10.0. Centrifuge to discharge the supernatant, that is, the first-stage alkaline hydrolysis effluent 6, and discharge the system; the residue after centrifugation, that is, the first-stage alkaline hydrolysis residue 2, is injected into the second-stage alkaline hydrolysis reactor. In the second-stage alkaline hydrolysis reactor B, inject 3 / 7X volume of water, adjust the pH to 13.0 with 10M sodium hydroxide solution while stirring at 150 rpm, and continue the alkaline hydrolysis reaction for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com