Patents

Literature

75 results about "Ammonium magnesium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

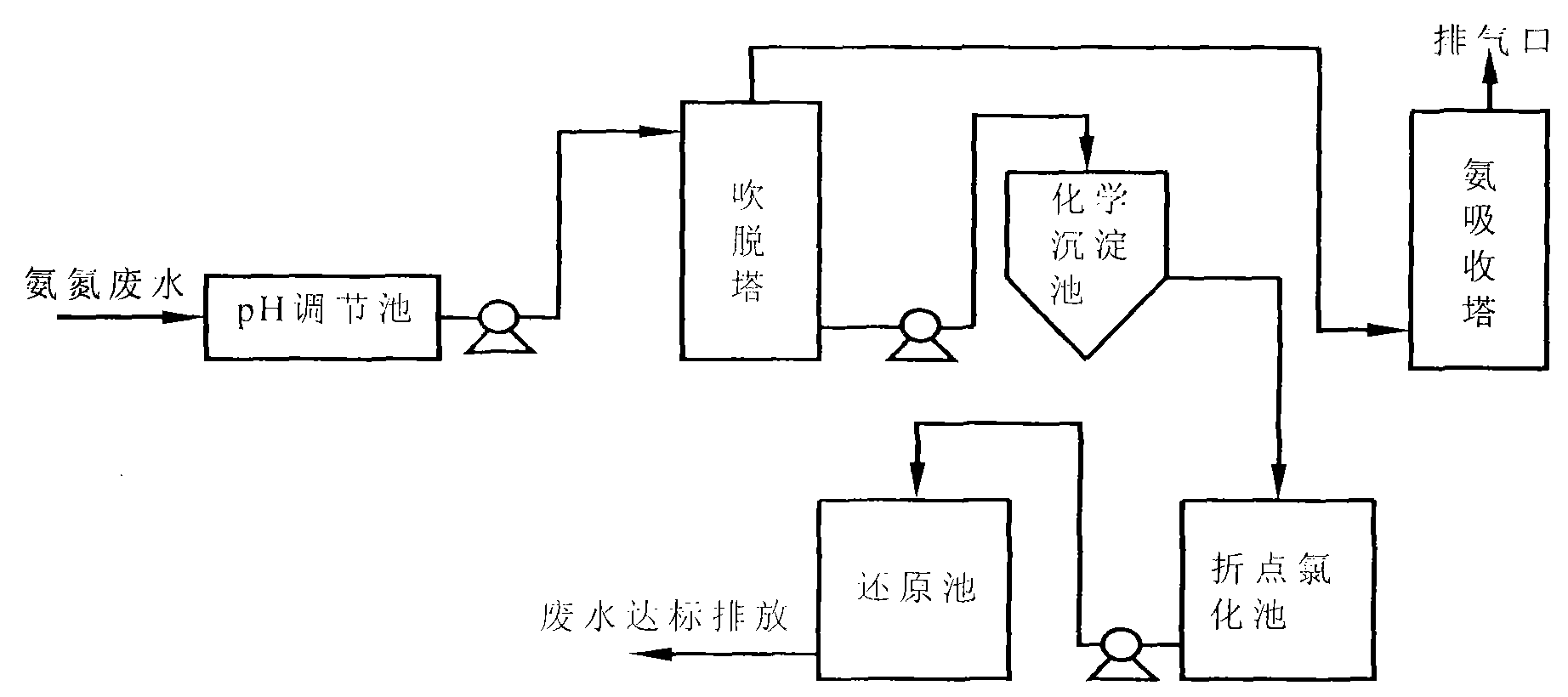

Method for treating highly concentrated ammonian wastewater with poor biodegradability by using a multiple-technique combination

InactiveCN101555077AShort processing cycleEasy to operateMultistage water/sewage treatmentWater/sewage treatment by neutralisationMagnesium saltEmission standard

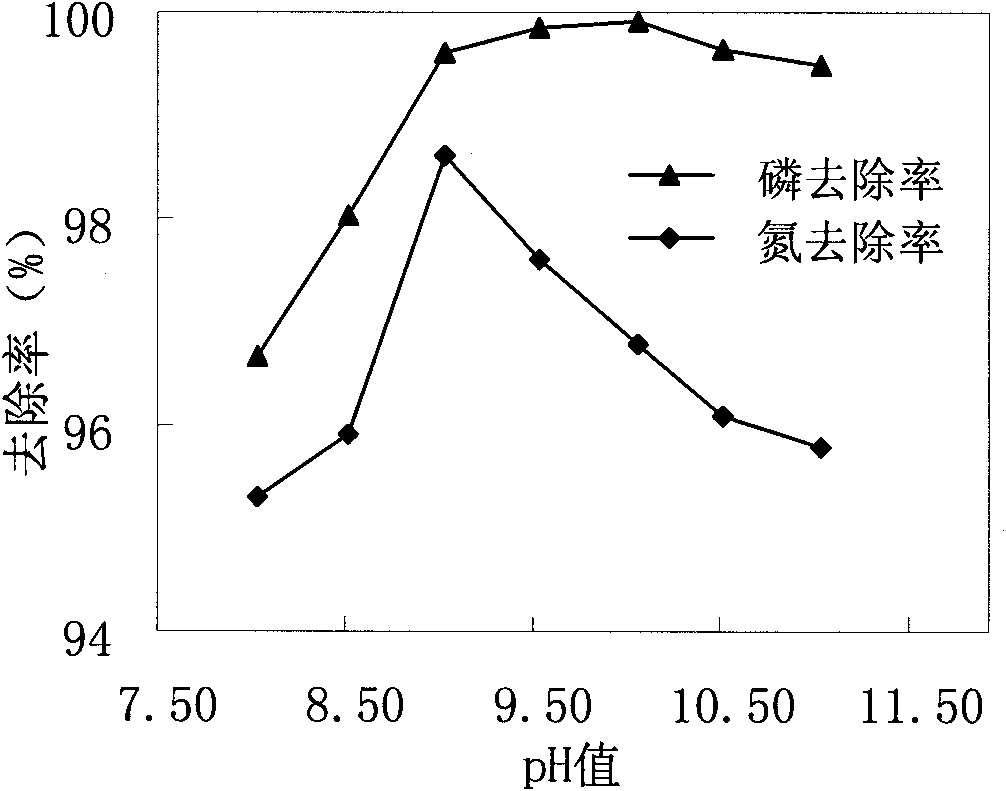

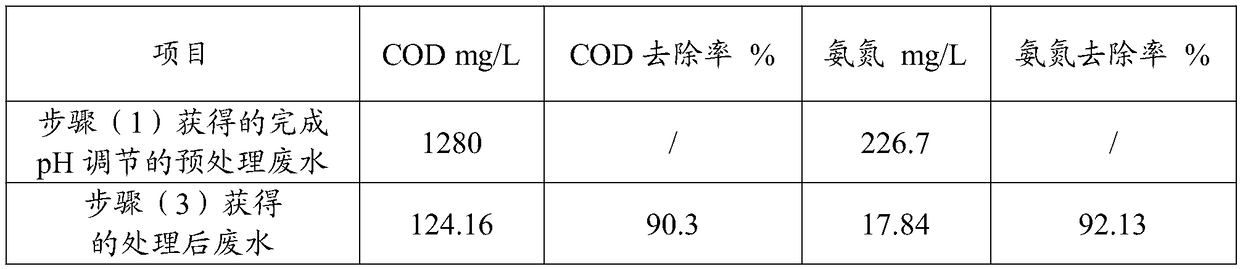

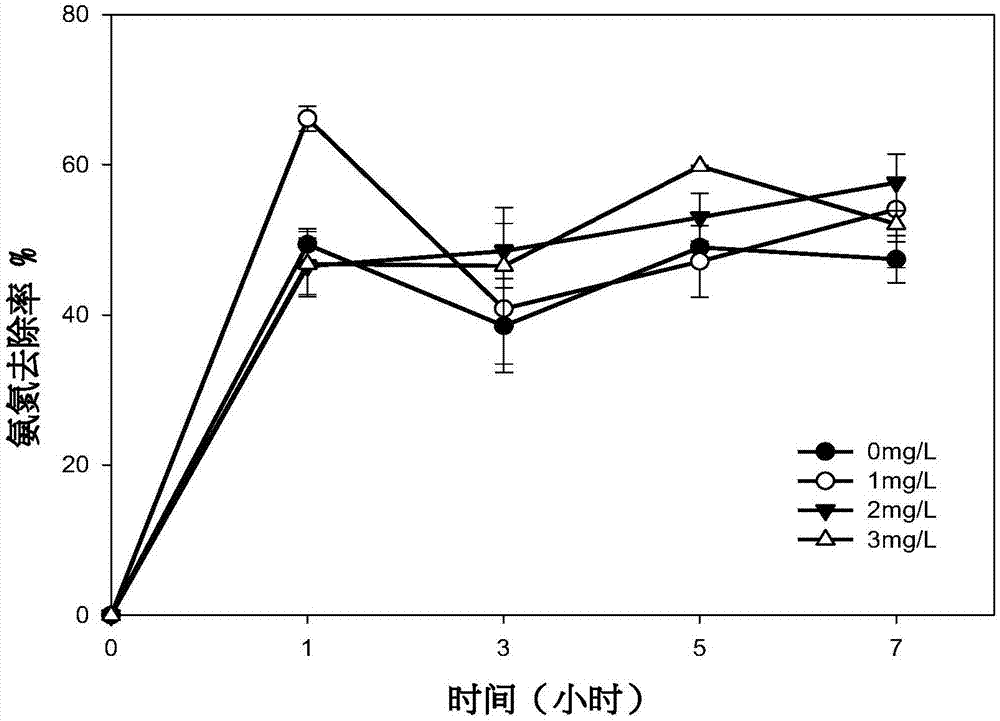

The invention relates to a method for treating highly concentrated ammonian wastewater with poor biodegradability by using a multiple-technique combination, which belongs to the technical field of wastewater treatment. The method is characterized in that: the ammonian wastewater primarily enters a pH adjusting tank for adjusting the pH value to be 11-12.5 and enters a blow-off tower for blowing off with the gas-liquid ratio being 3000-4500, the blown-off wastewater enters a chemical precipitation tank, magnesium salts and phosphates are added according to the mol ratio of Mg : N : P being 1.4-1.7:1:1 for reacting with the wastewater to generate ammonium magnesium phosphate precipitate for removing ammonian, yielding water enters a break point chlorination tank, chlorine-containing oxide is added according to the weight ratio Cl / N being 9-12:1 of active chlorine and ammonian, the wastewater is transferred to a reducing tank after the reaction, reducing agent is added according to 1-1.1 times of theoretical mol value of the yielding water completely reacting with residual chlorine, and the wastewater can be directly discharged after the reaction. The treatment method has simple operation, high reaction speed and low wastewater treatment cost, and can lead ammonian to be recovered without secondary pollution to environment; and the yielding water can reach primary emission standard.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

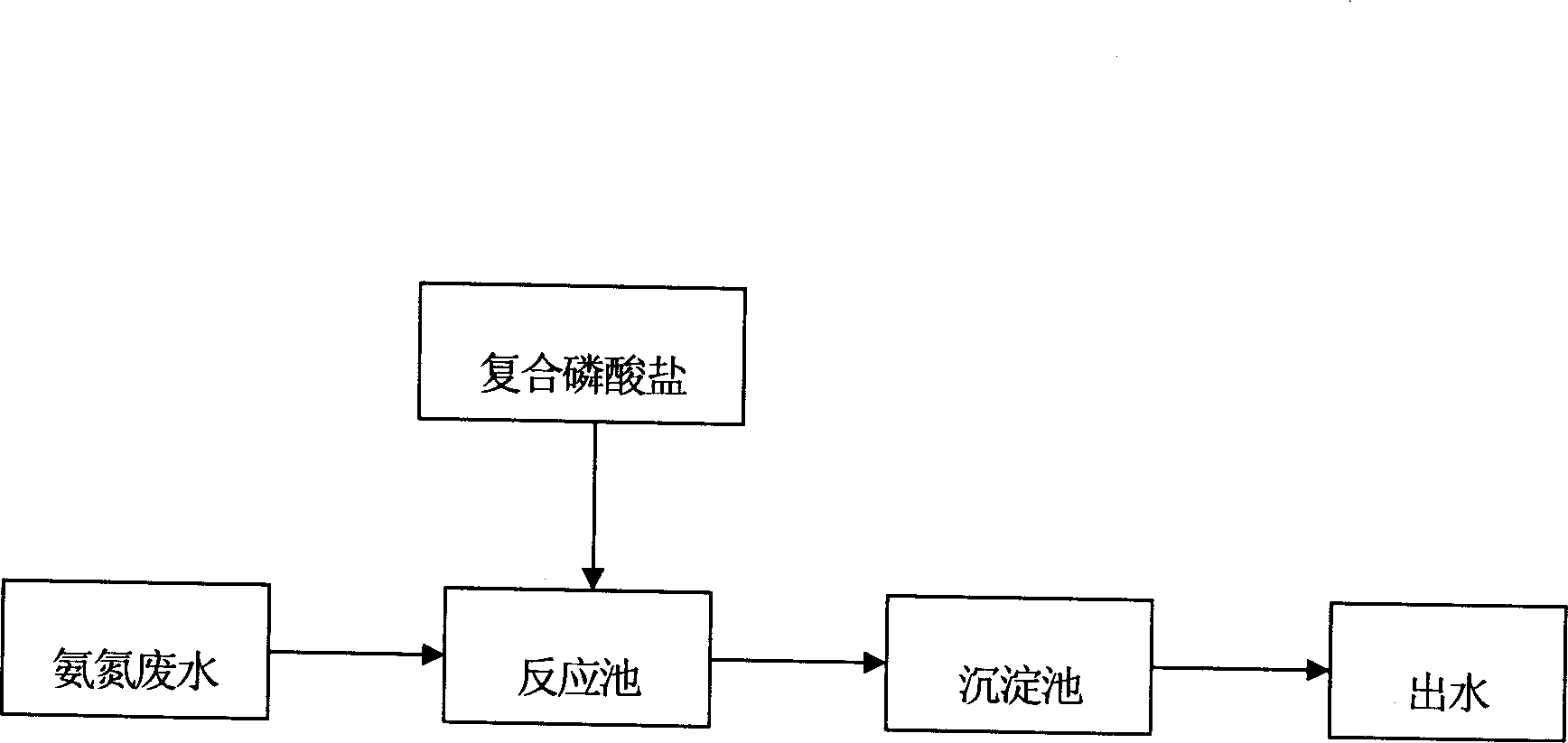

Pretreatment method for wastewater of ammonia nitrogen in high density

InactiveCN1872724AEfficient removalImprove removal efficiencyWater/sewage treatmentHigh concentrationPretreatment method

This invention discloses a method for pretreating high-concentration ammonia-nitrogen wastewater. The method comprises: (1) introducing ammonia nitrogen wastewater into a reactor; (2) adding composite phosphates that are composed of magnesium salt and two or more of phosphates, dihydrogen phosphates, hydrogen phosphates and phosphoric acid, and reacting at pH 8.0-9.5 for 10-60 min; (3) precipitating under gravity for 10-20 min, and discharging the supernatant. Compared with present techniques, the method uses composite phosphates to remove high-concentration ammonia-nitrogen, thus having some advantages. Besides, the method does not require the adjustment of pH value separately, and the obtained ammonium magnesium phosphate can be used as a fertilizer.

Owner:HARBIN INST OF TECH

Method for recycling magnesium from middle-low grade high-magnesium phosphate rock

The invention discloses a method for recycling magnesium from middle-low grade high-magnesium phosphate rock, which is used for pretreating phosphate rock serving as a raw material and recycling magnesium during wet phosphoric acid production. The method comprises the following steps of: removing magnesium from the middle-low grade high-magnesium phosphate rock with a magnesium removing agent by using a chemical method and dissolving most magnesium in the phosphate rock out of phosphate rock pulp; after a magnesium removing reaction is finished, performing solid-liquid separation on the formed pulp, wherein an obtained solid filter cake is magnesium-removed phosphate concentrate which can be put into the wet production of phosphoric acid; putting filtrate serving as magnesium-removed pulp into a next precipitation reaction procedure, adding an appropriate amount of neutralizing precipitant to adjust the pH value to 7.5-9.0 and undergoing a precipitation reaction; and performing solid-liquid separation after the reaction, and drying the solid precipitate which is ammonium magnesium phosphate with air stream to obtain a finished ammonium magnesium phosphate slow-release fertilizer. The obtained filtrate (containing ammonium sulfate) can be returned to wet phosphoric acid production.

Owner:中化重庆涪陵化工有限公司

Method for treating urban sewage with low carbon nitrogen ratio by using sludge liquor as carbon source

InactiveCN101575139AGood environmental benefitsSave double costBiological water/sewage treatmentChemistryCarbon source

The invention provides a method for treating urban sewage with low carbon nitrogen ratio by using sludge liquor as a carbon source, which pertains to the technical field of water treatment in environmental engineering. The technical proposal of the invention is characterized in that higher-content organic matters in sludge liquor of excess sludge after thermal decomposition are used as an external carbon source; concentration of ammonian in the sludge liquor of excess sludge after thermal decomposition is lowered by an ammoniomagnesium phosphate settling method, thus raising the C / N ratio of the sludge liquor; and the sludge liquor is applied to sewage of lower total nitrogen deprivation rate due to shortage of carbon source by appropriate proportion, thus achieving the purpose of raising the total nitrogen deprivation rate. Compared with the prior art, the method has the advantages of saving cost on traditional carbon source, facilitating the operation, and having excellent environmental, economic and social benefits by a strategy of controlling waste by waste. Therefore, the method provides a final solution to thermal decomposition of the sludge liquor of excess sludge for sewage treatment plants.

Owner:TSINGHUA UNIV

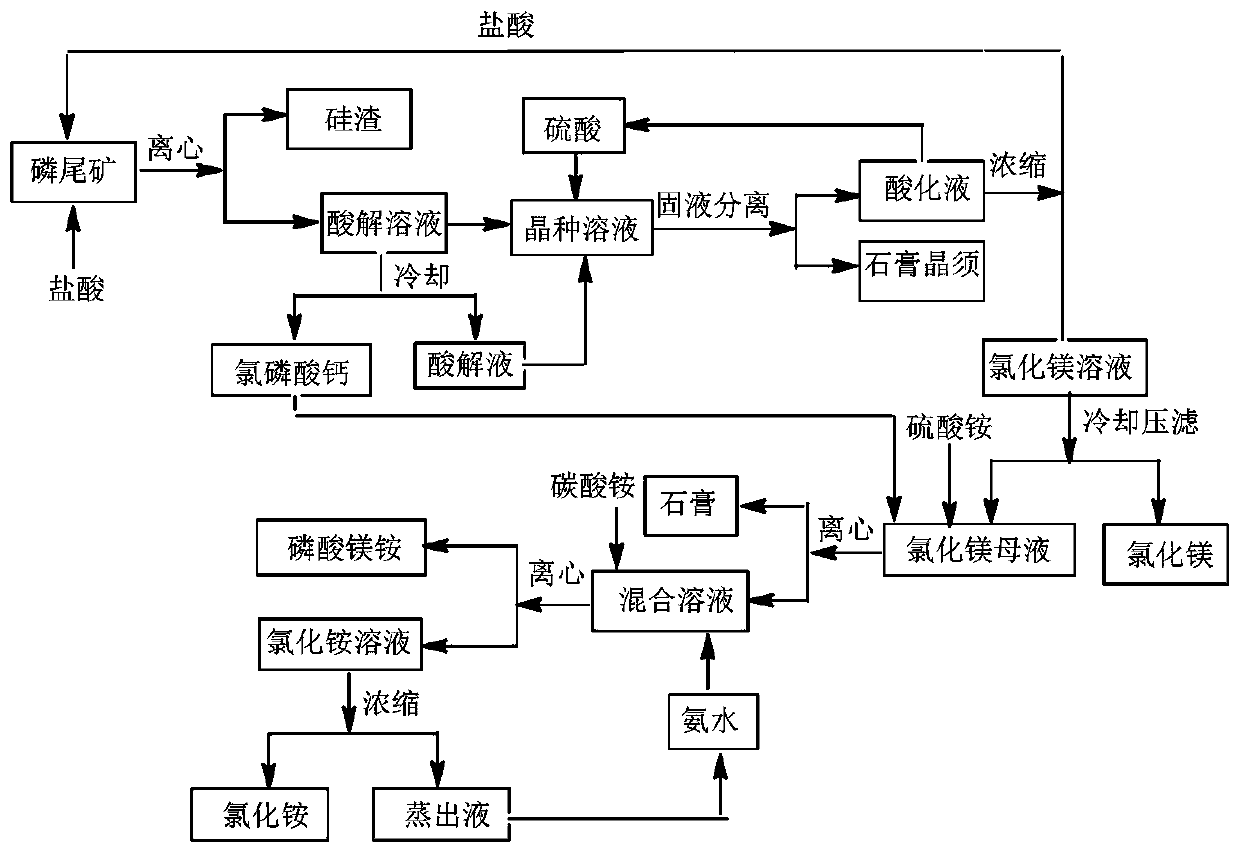

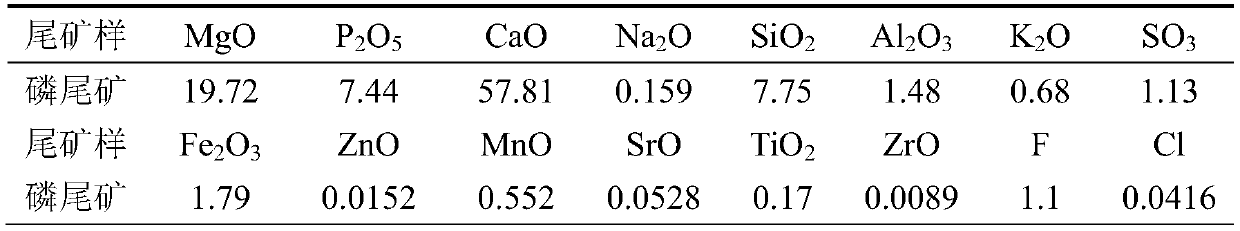

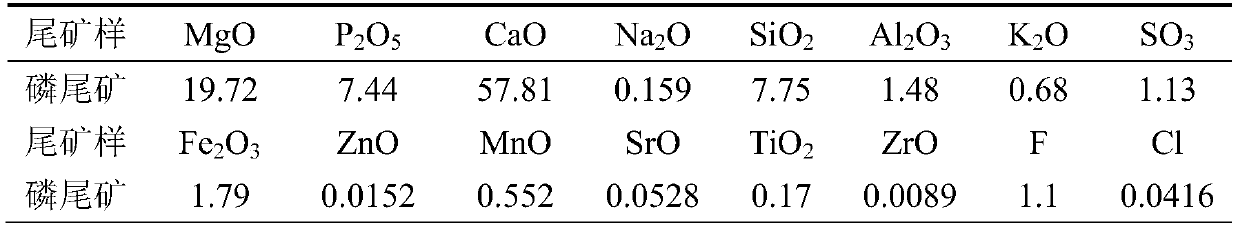

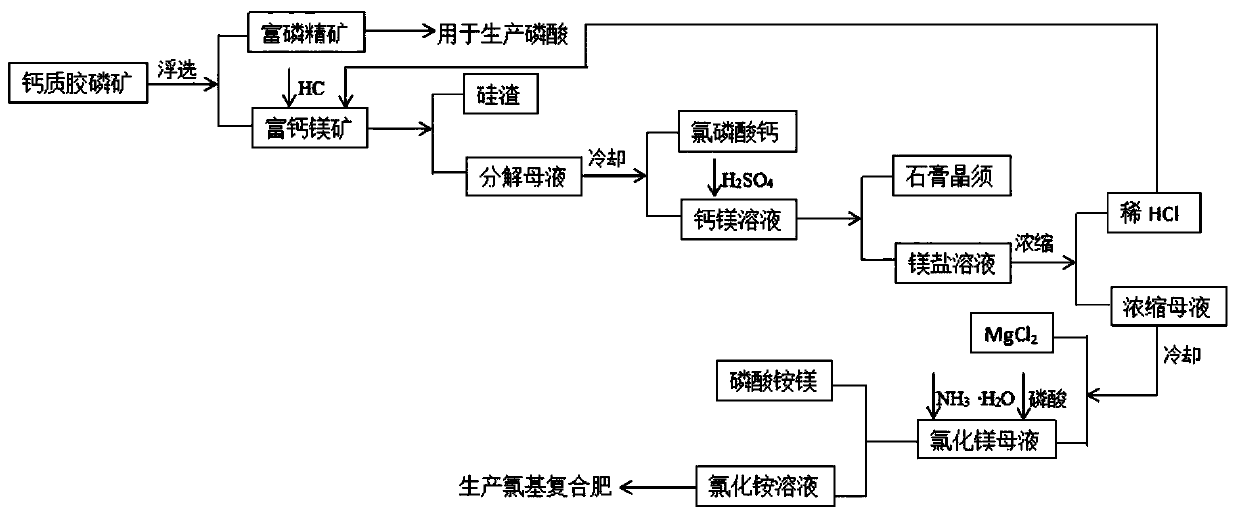

Method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings

ActiveCN110817911AHigh recovery rateSolve the bottleneck problem that cannot be consumed in large quantitiesPolycrystalline material growthFrom normal temperature solutionsMagnesium phosphatePhosphoric acid

The invention provides a method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings. The method comprises the following steps:adding an acidizing fluid into phosphate tailings in batches, dropwise adding hydrochloric acid to react, separating silicon slag and an acidolysis solution, and cooling and crystallizing the acidolysis solution to obtain calcium chlorophosphate and acidolysis solution; adding concentrated sulfuric acid into the acidizing fluid, dropwise adding the acidolysis fluid for reaction, and performing centrifugal separation after reaction to obtain gypsum whiskers and the acidizing fluid; heating and concentrating the acidizing fluid, crystallizing to obtain a magnesium chloride solution, and centrifugally separating the magnesium chloride solution to obtain magnesium chloride hexahydrate and a magnesium chloride mother liquor; adding ammonium sulfate and calcium chlorophosphate into the magnesium chloride mother liquor for reaction, filtering to obtain gypsum and a filtrate after the reaction is finished, dropwise adding ammonia water into the filtrate, cooling and filtering to obtain ammonium magnesium phosphate and an ammonium chloride solution; heating, concentrating, and cooling the ammonium chloride solution to obtain ammonium chloride crystals and a crystallization mother liquor, and after centrifugal separation, preparing a 5 to 20% ammonia water solution from the crystallization mother liquor and ammonia water. According to the technical scheme, the recovery rate of phosphorus reaches 99%, and the recovery rate of calcium reaches 95%.

Owner:三峡公共检验检测中心

Multifunctional special fertilizer for nursery stocks and preparation method thereof

InactiveCN104262031AThe ratio is scientific and comprehensiveIncrease profitSuperphosphatesAlkali orthophosphate fertiliserEcological environmentBuxus sinica

The invention discloses a multifunctional special fertilizer for nursery stocks and a preparation method thereof. The multifunctional special fertilizer for nursery stocks is prepared from the following raw materials in parts by weight: 30-40 parts of kitchen garbage, 15-25 parts of tea-seed pancake, 10-15 parts of stone coal flag, 12-18 parts of skin of bamboo shoots, 10-15 parts of coffee grounds, 16-22 parts of broken branches and fallen leaves, 10-15 parts of dry red soil, 8-16 parts of attapulgite, 5-10 parts of sea mud, 1.5-2.5 parts of strain powder, 15-20 parts of urea, 5-10 parts of ammonium magnesium phosphate, 10-15 parts of calcium superphosphate, 2-4 parts of potassium fulvic acid, 5-10 parts of sodium carboxymethyl starch, 4-8 parts of chitosan oligosaccharide, 3-6 parts of bone meal, 1-2 parts of zinc citrate, 1-2 parts of copper sulfate, 10-15 parts of opal, 12-16 parts of bryozoatum, 5-10 parts of coral sand, 2-3 parts of tobacco stems, 3-4 parts of tomato leaves, 1-2 parts of chenopodium ambrosioides, 2-3 parts of parepigynum funingense, 1.5-2.5 parts of masson pine and 1-2 parts of buxus sinica leaves. The fertilizer disclosed by the invention is high, long and comprehensive in fertilizer efficiency, the ecological environment of crops is improved, the plant diseases and insect pests of soil are restricted, the granular structure of soil is improved, the soil hardening is eliminated, the soil is loosened, the yield-increasing effect is obvious, and the crop quality is obviously improved.

Owner:CHONGQING UNIV OF ARTS & SCI

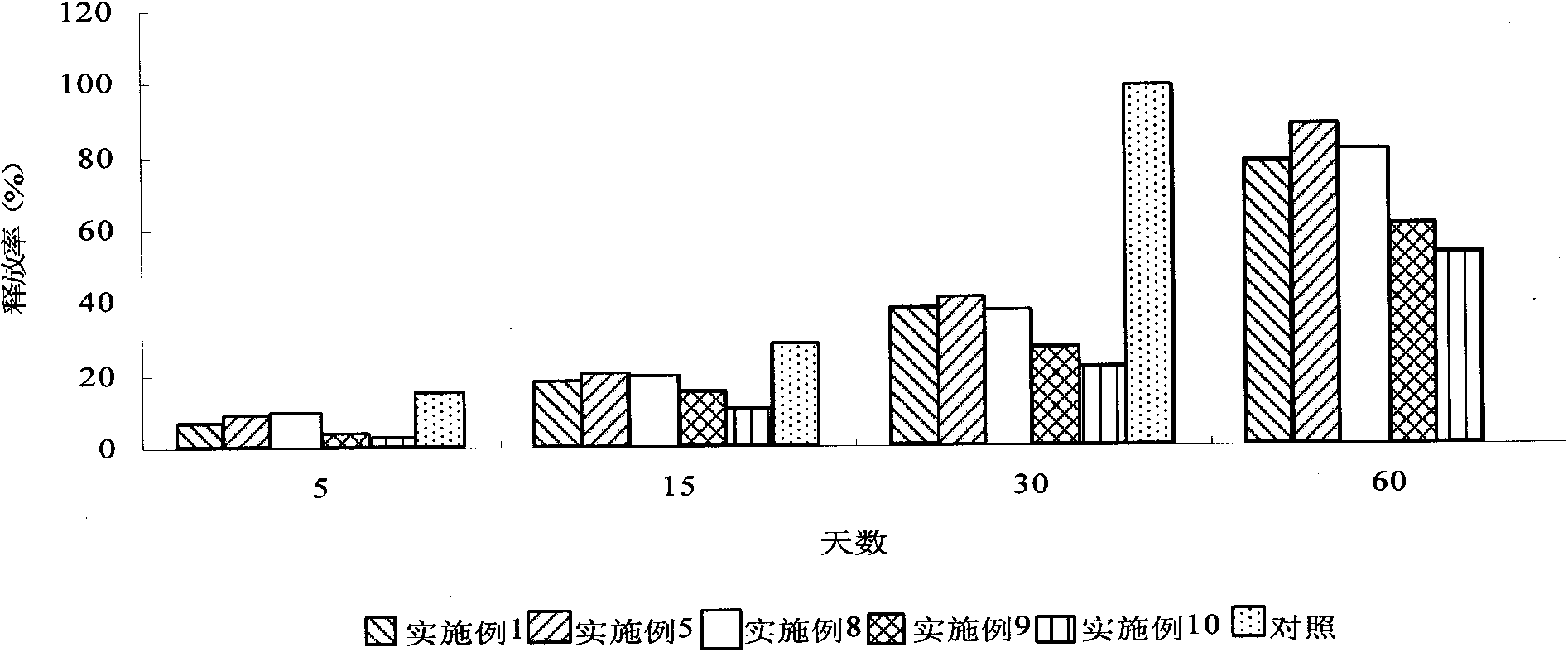

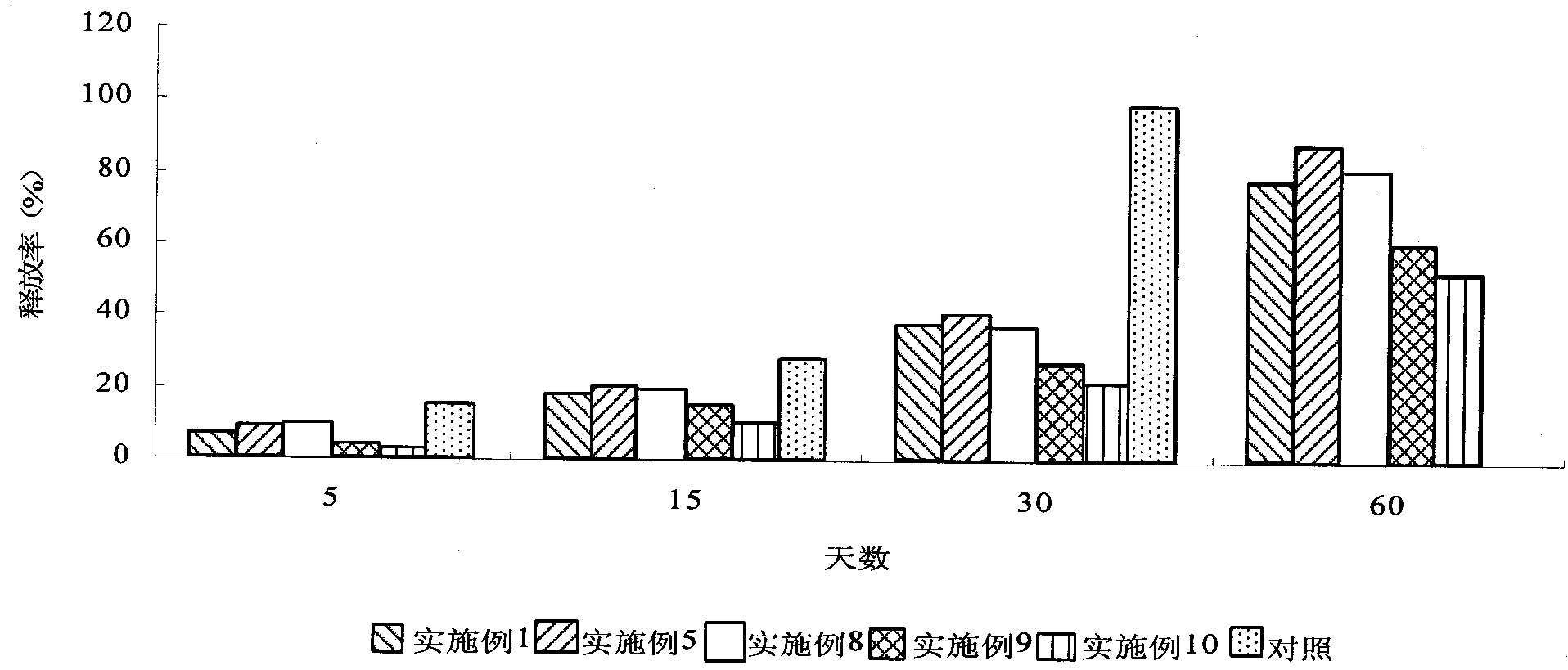

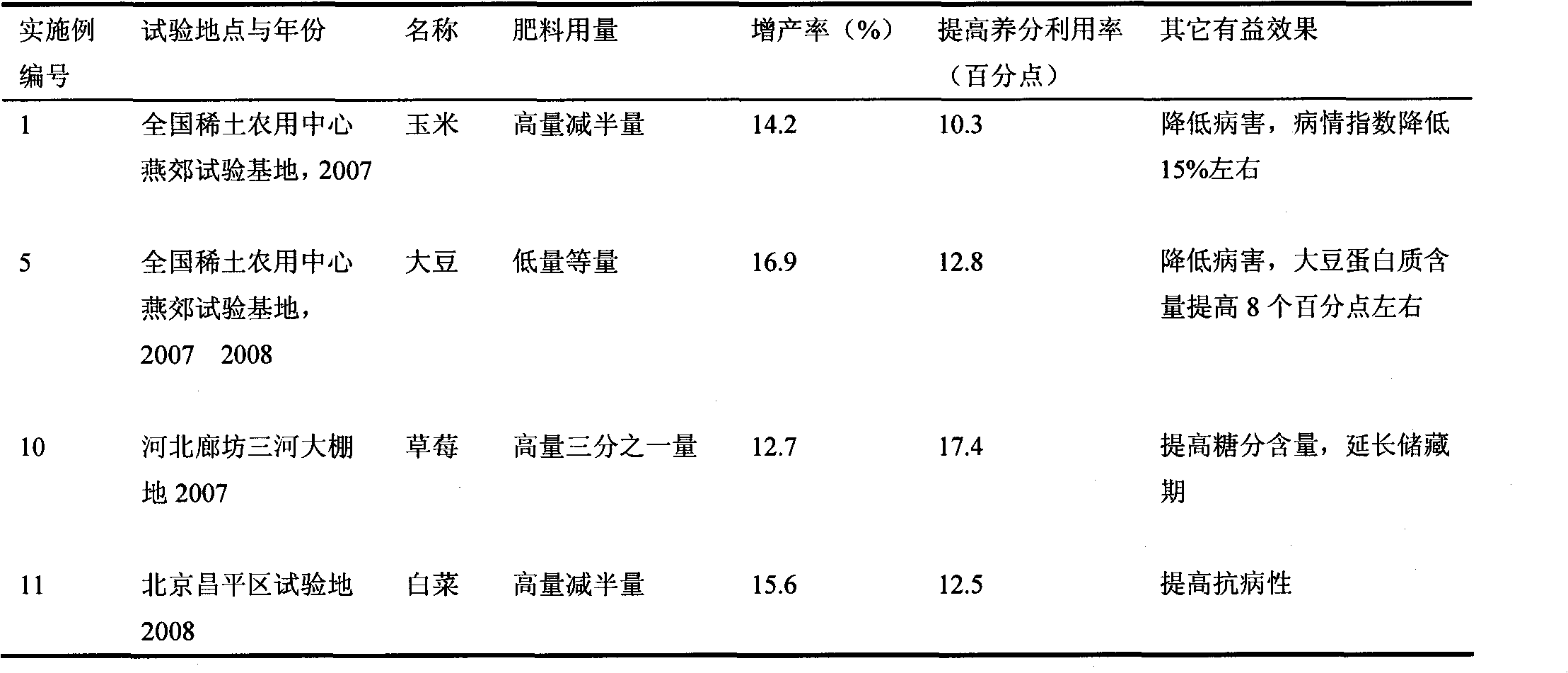

Ammonium magnesium phosphate slow release fertilizer and preparation method thereof

InactiveCN102249769AImprove utilization efficiencyPollution controlFertilizer mixturesPotassiumRare earth

The invention discloses an ammonium magnesium phosphate slow release fertilizer and a preparation method thereof, belonging to the technical field of waste water treatment. The ammonium magnesium phosphate slow release fertilizer contains at least one of potassium, iron, calcium, zinc, titanium and sulfur and a rare earth, wherein the rare earth is counted on the basis of the weight of an rare earth oxide (REO); the sum of the content of at least one of the potassium, iron, calcium, zinc, titanium and sulfur and the content of the REO is 0.01-10 percent by weight; the content of P2O5 is 15-49percent by weight; the content of N is 3-10 percent by weight; and the content of MgO is 16-26 percent by weight. In the preparation method, waste water is taken as a raw material, the ammonium magnesium phosphate slow release fertilizer is provided, so that valuable resources such as nitrogen, phosphorus, rare earth, magnesium and the like in the waste water are effectively recycled at low cost,the problem of waste water pollution is solved, and the valuable resources such as nitrogen, phosphorus, rare-earth, magnesium and the like in the waste water are effectively recycled at low cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

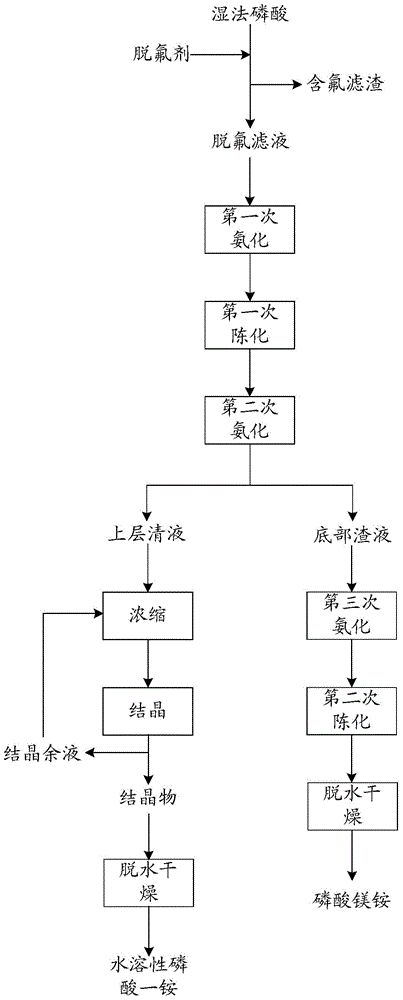

Method for producing fully water-soluble monoammonium phosphate and co-producing ammonium magnesium phosphate by wet process phosphoric acid

The invention provides a method for producing fully water-soluble monoammonium phosphate and co-producing ammonium magnesium phosphate by a wet process phosphoric acid. The method comprises the following steps: deflurinating the wet process phosphoric acid and taking deflurinating filtrate; carrying out first ammoniated treatment on the deflurinating filtrate until the pH value is 2.0-3.0, and then first ageing to obtain a first ageing solution; carrying out second ammoniated treatment on the first ageing solution until the pH value is 4.0-5.0, and carrying out solid-liquid separation to obtain supernatant liquid and bottom slag liquid; carrying out concentration, crystallization and crystal-liquid separation on the supernatant liquid to obtain a crystal substance which is a monoammonium phosphate product; and carrying out third ammoniated treatment on the bottom slag liquid until the pH value is 5.6-6.0, carrying out second ageing and drying to obtain an ammonium magnesium phosphate product. According to the method provided by the invention, products of the fully water-soluble monoammonium phosphate and the ammonium magnesium phosphate are produced by three ammoniated treatments and one separation, iron and aluminum crystals gradually grow by ageing for a period of time after the first ammoniated treatment, precipitate particle size is increased, filtering performance is improved, impurity ions can be totally precipitated by the second ammoniated treatment, and water solubility of the monoammonium phosphate product is improved remarkably.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Method for utilizing coal ash to prepare slow-release fertilizer

ActiveCN108976040APenetrate fastReduce evaporationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil propertiesPhosphoric acid

The invention discloses a method for utilizing coal ash to prepare slow-release fertilizer. The coal ash is levigated and sieved, sodium hydroxide and magnesium hydrate are added into the obtained screen underflow and mixed to be uniform, the mixture is placed into a rotary kiln to be calcinated, and a calcinated material is obtained; hot water is added into the calcinated material to pulpify thecalcinated material, then the product is filtered, first filtered liquid and first filtered residue are obtained, an ammonium sulfate solution is added into the obtained first filtered residue, then aphosphoric acid solution is added to condition the pH value of the solution, diammonium hydrogen phosphate is added and stirred to react, the product is filtered, and second filtered liquid and second filtered residue are obtained; and the second filtered residue is dried, crushed, and screened, and the slow-release fertilizer is obtained. The slow-release fertilizer is obtained by taking the coal ash as the carrier and loading ammonium magnesium phosphate on the coal ash, the fertilizer efficiency release time is improved by 20% or above than simple ammonium magnesium phosphate slow-releasefertilizer, the soil property can be improved as well, the soil is loosened, the water permeating speed of the soil is increased, and the fertilizer can adsorb water, and achieves the effect of waterconservation.

Owner:湖南斯多瑞农业发展有限公司

Ammonium magnesium phosphate sustained-release fertilizer containing rare-earth complex salts and preparation method thereof

InactiveCN102249768AImprove utilization efficiencyControl environmental pollutionFertilizer mixturesSulfate radicalsIndustrial waste water

The invention discloses an ammonium magnesium phosphate sustained-release fertilizer containing rare-earth complex salts and a preparation method thereof, and belongs to the technical field of fertilizer preparation. The sustained-release fertilizer contains rare-earth complex salts; the content of the rare-earth complex salts is 0.01 to 5.0 weight percent based on rare-earth oxides (REO); and the rare-earth complex salts are at least one of rare-earth complex sulfate, rare-earth complex carbonate, rare-earth complex nitrate and rare-earth complex oxalate. The preparation method comprises the following steps of: premixing waste solution containing rare-earth ions, magnesium ions and ammonium ions and waste solution containing at least one kind of ions of sulfate radical, nitrate radical, carbonate radical and oxalate radical, regulating the pH to be between 1 and 4.5, adding waste solution containing phosphate radical ions after reacting, regulating the pH to be between 8 and 11 by using an alkali substance, and performing post treatment on the sediment obtained by the reaction to obtain the ammonium magnesium phosphate sustained-release fertilizer containing rare-earth complex salts. The ammonium magnesium phosphate sustained-release fertilizer containing the rare-earth complex salts is prepared by using rare-earth industrial waste water and other industrial waste water, so that beneficial elements such as rare earth, nitrogen, phosphorus and the like are slowly released, and the utilization efficiency of the fertilizer is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

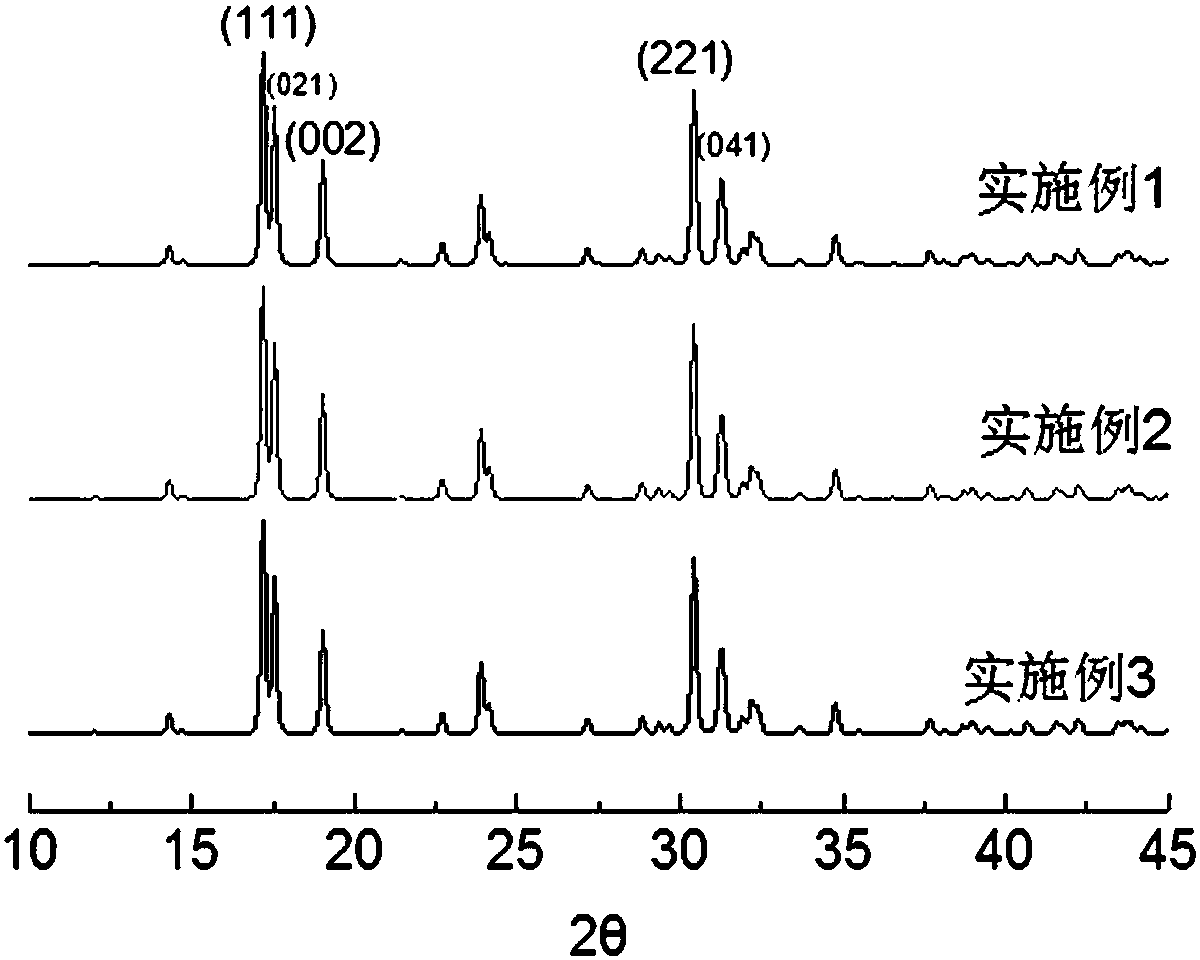

Method for preparing ammonium magnesium phosphate monohydrate slow-release fertilizer

InactiveCN101100398ANo pollution in the processFertilizer slow releasePhosphorus compoundsNuclear chemistryAmmonium magnesium phosphate

Production of ammonium magnesium phosphate monohydrate is carried out by putting monohydrate ammonium-magnesium phosphate 1500 kg, 90% magnesium hydrate 640 kg, and mono-ammonium phosphate 1150 kg into reactor, then adding into water 2000 kg, heating to 90 deg. C, agitating for 1 hr to generate ammonium-magnesium phosphate hexahydrate, centrifugal separating while depositing, drying by hot air at 105 deg. C for 3 hrs to obtain slow-release fertilizer 1550 kg. It has less labor strength and no environmental pollution.

Owner:TIANJIN HANGU DISTRICT FUXIANG FERTILIZER PROCESSING FACTORY

Wet desulfurization wastewater treatment method

InactiveCN109354248AHigh removal rateRaise the pHWater treatment compoundsWater contaminantsMagnesium phosphateFerrous salts

The invention belongs to the field of wastewater treatment, and particularly relates to a wet desulfurization wastewater treatment method. The wet desulfurization wastewater treatment method comprisesthe following steps that 1, the pH value of desulfurization wastewater is regulated to 2.25-4.5, then, the desulfurization wastewater is mixed and reacts with hydrogen peroxide and ferrite, and oxidized wastewater is obtained; 2, the oxidized wastewater and calcium peroxide are subjected to a mixed reaction, precipitates are removed, and a clear solution is obtained; 3, in the presence of Mg2+, the clear solution and diphosphate are subjected to a mixed reaction, precipitates are removed, and processed wastewater is obtained; the source of Mg2+ is additionally added Mg2+ and / or Mg2+ containedin the clear solution. By combining Fenton oxidation, calcium and silicon composite precipitates and zinc and magnesium phosphate precipitation technology, desulfurization wastewater is treated, andCOD and ammonia nitrogen in the wet desulfurization wastewater can be efficiently removed.

Owner:XIANGTAN UNIV

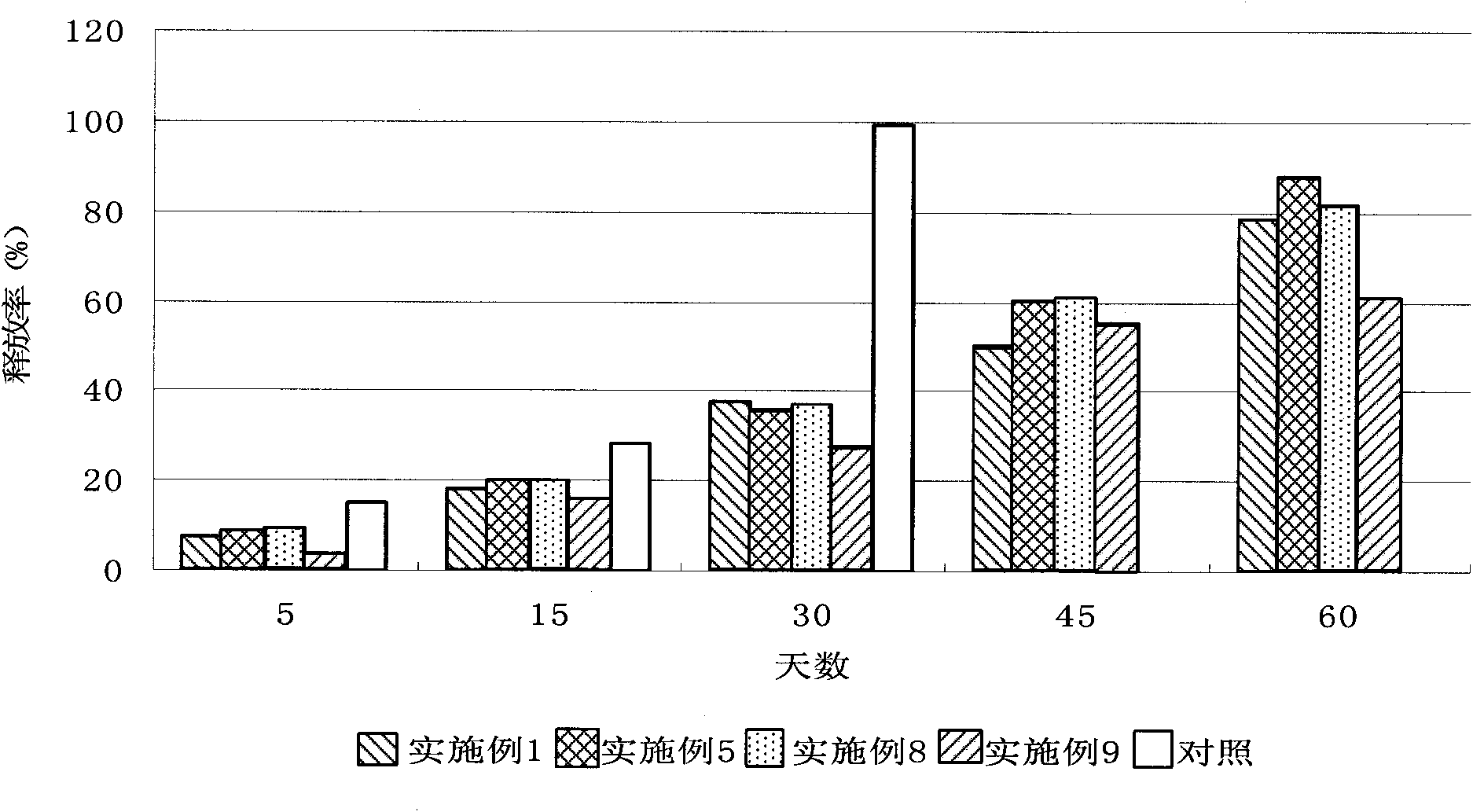

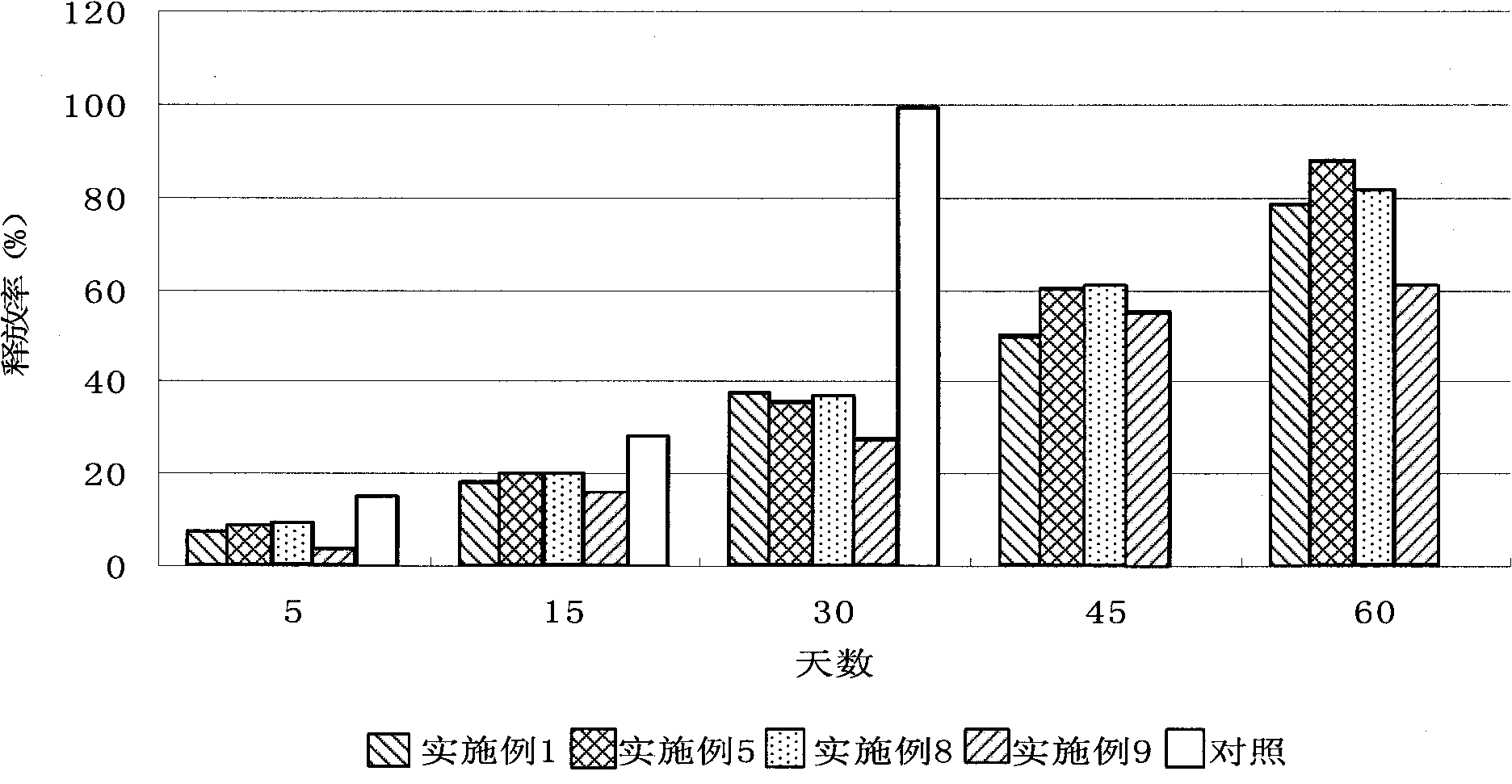

Coated fertilizer for improving acidic soil and preparation method thereof

InactiveCN107586205AEfficient use ofMeet needsFertilizer mixturesCarboxymethyl celluloseAttapulgus clay

The invention discloses coated fertilizer for improving acidic soil and a preparation method thereof. The preparation method comprises the following steps: (1) pre-heating fertilizer particles; (2) stirring and mixing ammonium magnesium phosphate, sodium carboxymethyl cellulose and oil to obtain coating homogenized paste; (3) uniformly spraying the coating homogenized paste on the surfaces of thefertilizer particles which are pre-heated in step (1); (4) after uniformly mixing biological charcoal powder and palygorskite powder, covering the mixture on the product obtained by step (3) to prepare the coated fertilizer. According to the coated fertilizer prepared by the preparation method, the fertilizer is coated with a special material, so that the aims of postponing a nutrient releasing speed and delaying the validity period of the fertilizer are realized. The coated fertilizer is convenient to apply; after the coated fertilizer is applied into soil, the fertilizer is gradually decomposed under the action of chemical and biological factors; nutrients are slowly released, and requirements of crops for the nutrients in a whole growth period can be met.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Compound fertilizer with sterilization function

InactiveCN105175128AThe preparation process is simpleShortened maturation timeFertilizer mixturesPoultry manureFurfural

The invention relates to a compound fertilizer with a sterilization function, which is prepared from the following components in parts by weight: 36 to 40 parts of ammonium dihydrogen phosphate, 38 to 42 parts of wormcast, 34 to 38 parts of bagasse, 38 to 42 parts of flour weevil powder, 34 to 38 parts of ground phosphate rock, 38 to 42 parts of heteroauxin, 34 to 38 parts of medical stone powder, 40 to 44 parts of livestock and poultry manure, 34 to 38 parts of ground corncob, 38 to 42 parts of ammonium magnesium phosphate, 34 to 38 parts of amino acid powder, 38 to 42 parts of itaconic acid, 34 to 38 parts of compound sodium nitrophenolate, 38 to 42 parts of algae powder, 34 to 38 parts of probiotics, 38 to 42 parts of chitin, 34 to 38 parts of picoxystrobin, 38 to 42 parts of propamocarb, 34 to 38 parts of furfural residue, 38 to 42 parts of benfuracarb, 34 to 38 parts of sodium molybdate, 38 to 42 parts of dodecyl polyglucoside and 1000 to 2000 parts of water. The compound fertilizer has excellent nutritive elements and good antibacterial and insecticidal properties, is suitable for being used in the field of agriculture, and shortens the ripening time of plants.

Owner:龚灿锋

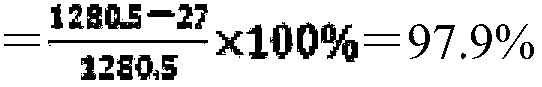

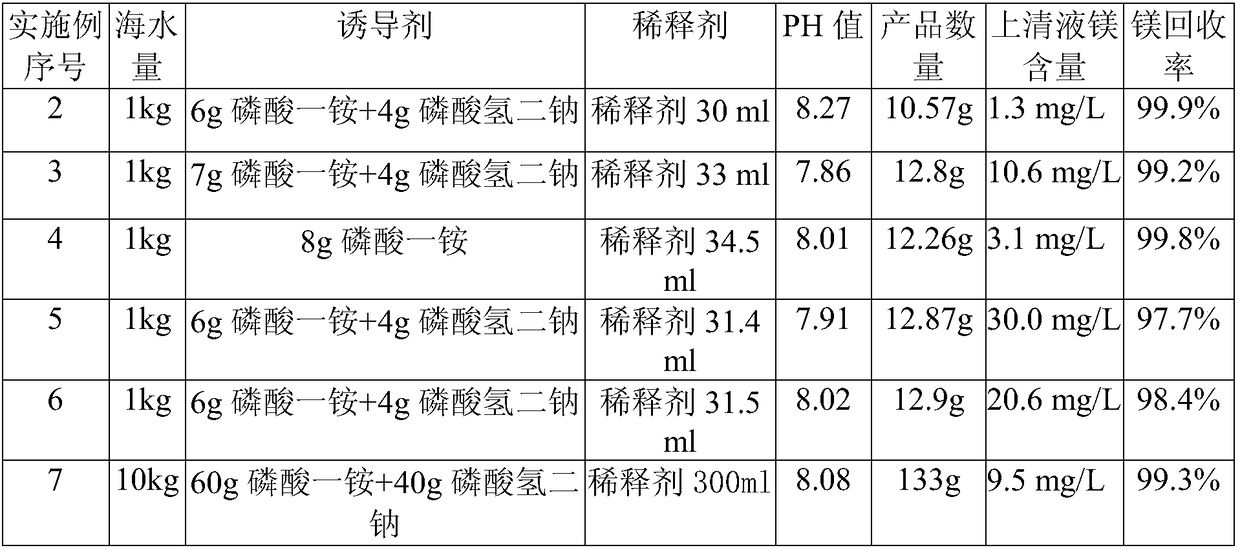

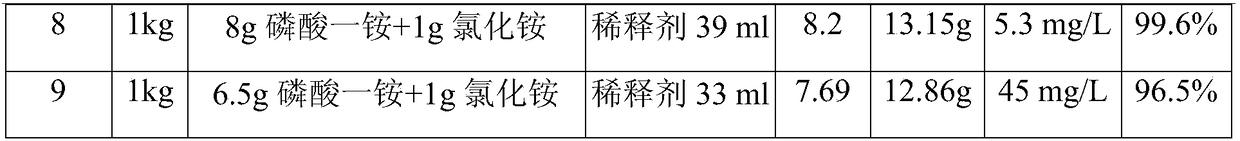

Method using sea water or brine to produce ammonium magnesium phosphate

ActiveCN108569684AHigh recovery rateEliminate the material basisPhosphorus compoundsSolubilityMagnesium phosphate

The invention relates to a method using sea water or brine to produce ammonium magnesium phosphate. The method includes the steps of firstly, adding an inducer into the sea water or brine, and evenlymixing; secondly, adding a diluent into the seawater or brine, and regulate pH to allow the pH to stably be 7-9; thirdly, performing standing settling for 1-12 hours, wherein the reaction system is divided into supernate and solid sediments after the standing settling; fourthly, performing solid-liquid separation to obtain the solid sediments, namely ammonium magnesium phosphate. Compared with theprior art, the method has the advantages that ammonium magnesium phosphate low in solubility product is produced to recycle magnesium ions, and high magnesium recycling rate is achieved; due to the fact that the ammonium magnesium phosphate is more expensive than magnesium hydroxide, the method is good in economic benefits; when the magnesium ions in the sea water or brine is recycled, other divalent (or above) ions are partially and completely precipitated, the material basis for forming water scale is basically eliminated in the supernate obtained after the sediments are separated, and convenience is brought to subsequent treatment.

Owner:山东和生海洋科技有限公司

High-latitude region stevia rebaudiana special-purpose fertilizer

InactiveCN106588460AAddress nutritional needsReasonable ratioMagnesium fertilisersAlkali orthophosphate fertiliserFiberGrape seed

The invention discloses a high-latitude region stevia rebaudiana special-purpose fertilizer. The high-latitude region stevia rebaudiana special-purpose fertilizer comprises the following raw materials in parts by weight: 25-35 parts of ammonium hydrogen phosphate, 5-15 parts of ammonium sulfate, 2-12 parts of rock phosphate, 10-18 parts of a kiln dust potash fertilizer, 0.2-0.8 parts of boron magnesium fertilizer zinc, 0.4-0.9 parts of hexaurea iron(III) trinitrate, 2-6 parts of ammonium magnesium phosphate, 0.5-1.2 parts of ammonium molybdate, 1-2 parts of a boron magnesium fertilizer, 5-10 parts of fermented corn straw, 2-8 parts of earthworm manure, 2-10 parts of Chinese medicine residue, 2-8 parts of bentonite, 20-40 parts of grape seed cake, 15-35 parts of rice bran, 5-15 parts of linen fiber composite clay, 1-4 parts of carbonized corncob powder, 1-2 parts of kaolin, 1-2 parts of fly ash, 2-4 parts of meerschaum, 1-6 parts of carboxymethyl cellulose, and 1-2 parts of brewer's grain. The nutrient element ratio is reasonable, the nutrition requirement problem of stevia rebaudiana can be solved after application, fertilizer utilization rate is increased, and the environment pollution due to fertilizer loss is reduced.

Owner:黄璜

Degradable slow release fertilizer containing magnesium sulfate and preparing method thereof

InactiveCN106699455AImprove adsorption capacityClosely connectedMagnesium fertilisersAlkali orthophosphate fertiliserAmmonium nitratePollution

The invention discloses a degradable slow release fertilizer containing magnesium sulfate. The fertilizer is prepared from, by weight, 10-20 parts of potassium phosphate, 10-20 parts of ammonium nitrate, 10-12 parts of ammonium dihydrogen phosphate, 5-10 parts of potassium nitrate, 10-15 parts of urea, 0.4-0.5 part of ammonium magnesium phosphate, 0.2-0.4 part of zinc sulfate, 0.2-0.4 part of magnesium sulfate, 0.2-0.3 part of ferric chloride, 0.1-0.2 part of manganese sulfate, 10-15 parts of charcoal, 5-10 parts of humic acid and 30-40 parts of coated material. The invention further discloses a preparing method of the degradable slow release fertilizer containing magnesium sulfate. The degradable slow release fertilizer containing magnesium sulfate is balanced in nutrition, can release nutrient slowly, and avoid pollution to the environment caused by nutrient loss; the water retention coated material can be degraded, which avoids secondary pollution to the environment, and meanwhile the material can retain water and fertilizer, improve the soil environment, and promote the crop growth.

Owner:芜湖市皖镁实业有限公司

Preparation method for ammonium-polyphosphate-doped magnesium aluminium hydrotalcite

InactiveCN104591238ALow costSimple processHydrotalciteAluminium oxides/hydroxidesSlurrySodium carbonate anhydrous

The invention discloses a preparation method for ammonium-polyphosphate-doped magnesium aluminium hydrotalcite. The preparation method comprises: fully grinding magnesium sulfate and aluminium nitrate in a mortar, putting the grinded mixed powder into deionized water for dissolving, adding sodium hydroxide and an anhydrous sodium carbonate solution with stirring, keep pH at 9-12, performing magnetic stirring at room temperature for 20 min, then adding urea and deionized water, heating to 50 DEG C and stirring for 1 h, after the reaction is finished, putting the slurry into a microwave extraction instrument, controlling the power to be 500 W, crystallizing at 150 DEG C, drying, grinding into a powder, putting the crystal powder into a reaction flask, adding deionized water and APP, heating to 120 DEG C, slowly stirring, after the reaction is finished, ageing in the pot for 10 h, cooling and drying, so as to obtain ammonium-polyphosphate-doped magnesium aluminium hydrotalcite. The method is economic and practical, low in cost, simple in technology, high in efficiency and high in quality.

Owner:CHANGZHOU UNIV

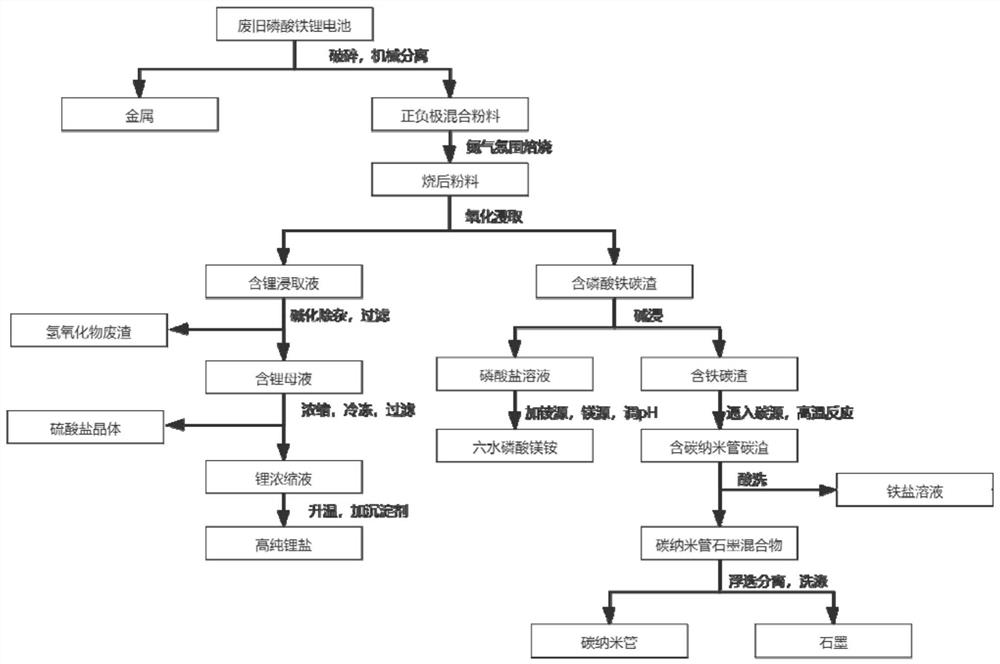

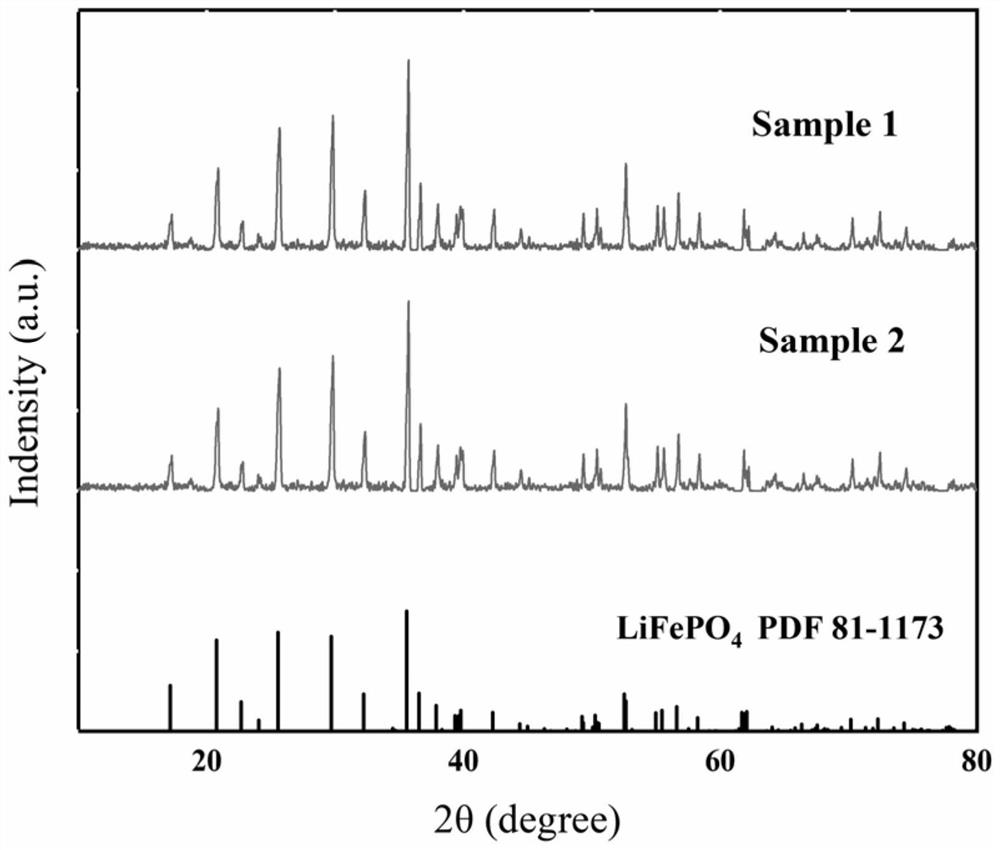

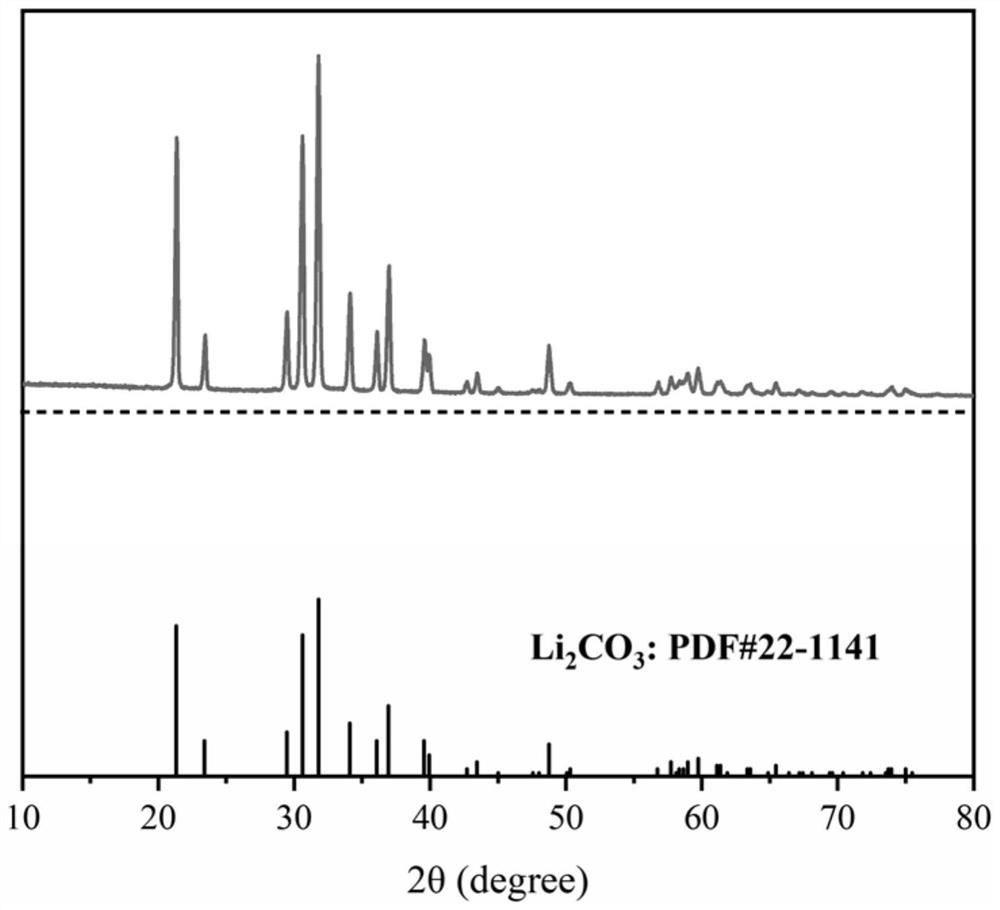

Method for recycling waste lithium iron phosphate battery

ActiveCN113793994AAvoid pollutionHigh economic valueGraphiteCarbon nanotubesMagnesium phosphatePtru catalyst

The invention discloses a method for recycling waste lithium iron phosphate batteries. The method comprises the following steps: (1) roasting: roasting to remove surface hydrophobic substances; (2) oxidation leaching: dissolving a Li metal element; (3) impurity removal: carrying out precipitating to remove Fe, Al and Cu elements in the filtrate; (4) lithium precipitation: precipitating and recovering a lithium compound; (5) phosphorus precipitation: precipitating the phosphorus element in the filtrate into ammonium magnesium phosphate hexahydrate; (6) growing of a carbon nano tube: introducing a gaseous carbon-containing substance to deposit and grow into the carbon nano tube; (7) pickling: removing the Fe element; (8) flotation separation: separating the carbon nanotube suspension from the graphite to obtain the carbon nanotube and the graphite. According to the method, the green and environment-friendly oxidizing agent is used, most of lithium and iron elements are selectively recycled to serve as catalysts for growing the carbon nanotubes, phosphorus is converted into slow-release fertilizer ammonium magnesium phosphate with good performance, waste graphite is recycled together, secondary pollution is avoided, and the problem that a traditional recycling process has negative economic benefits can be solved.

Owner:XI AN JIAOTONG UNIV

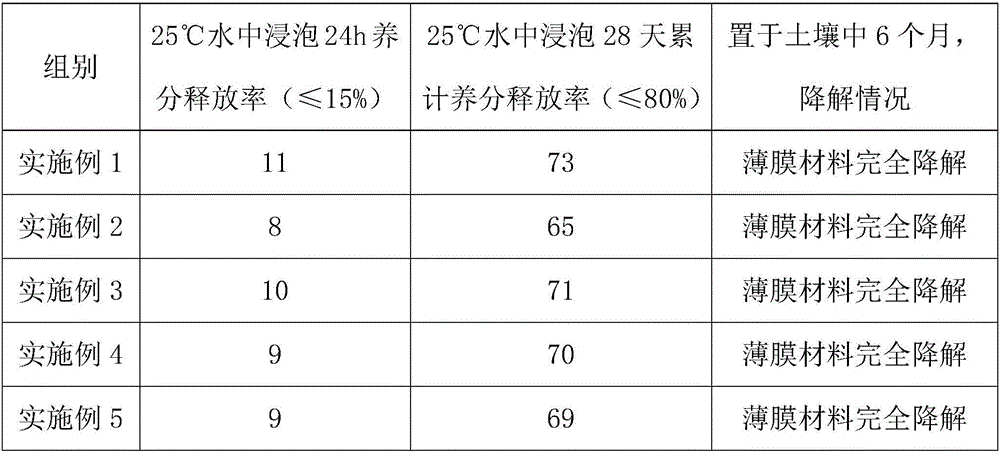

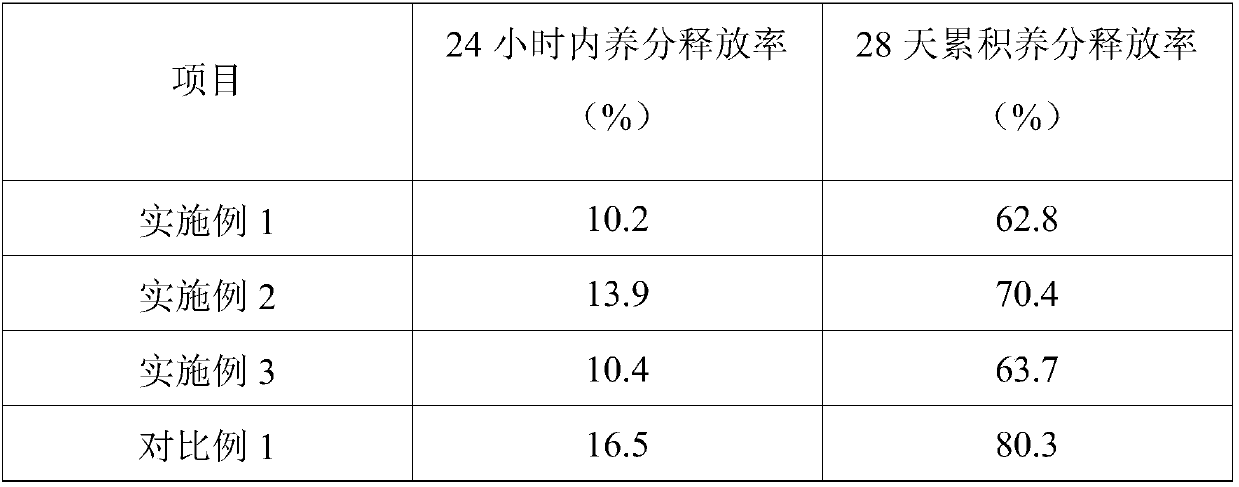

Ammonium magnesium phosphate-coated fertilizer and preparation method thereof

ActiveCN107652049ALong release periodReduce decompositionCalcareous fertilisersMagnesium fertilisersAmmonium magnesium phosphateNutrient

The invention discloses an ammonium magnesium phosphate-coated fertilizer and a preparation method thereof. The preparation method includes spraying ammonium magnesium phosphate powder on the surfacesof fertilizer granules sprayed with preheated binders evenly, drying and spraying a sealing agent on the fertilizer granules coated with the ammonium magnesium phosphate. The ammonium magnesium phosphate-coated fertilizer prepared according to the preparation method has the advantages that with paraffin as the sealing agent, the coating effect can be better and the nutrient release period of thefertilizer can be prolonged, brittleness of an ammonium magnesium phosphate coating can be reduced and impact resistance of the coated fertilizer is improved; the ammonium magnesium phosphate-coated fertilizer can be up to the standards of slow-release fertilizers, the initial nutrient release rate is not more than 15%, the accumulated nutrient release rate in 28 days is not more than 80%, and theaccumulated nutrient release rate in the nutrient release period is not less than 80%.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Method for producing phosphate concentrate from calcareous collophanite and by-producing gypsum whiskers and magnesium ammonium phosphate

PendingCN111483989AImprove Phosphorus TasteIncrease added valuePolycrystalline material growthFrom normal temperature solutionsMagnesium phosphateO-Phosphoric Acid

The invention provides a method for producing phosphate concentrate from calcareous collophanite and by-producing gypsum whiskers and magnesium ammonium phosphate, and the method comprises the following steps: separating the phosphate concentrate and calcium-rich and magnesium-rich tailings from the calcareous collophanite by flotation, and carrying out acidolysis on the calcium-rich and magnesium-rich tailings to extract available valuable elements in the tailings, thereby obtaining the gypsum whiskers and the ammonium magnesium phosphate product. The method comprises the following steps: firstly, carrying out flotation on the calcareous collophanite; comprehensively utilizing calcium, magnesium and phosphorus elements in the tailings obtained by flotation; the phosphorus taste of the collophanite is improved, the collophanite can be directly used for wet-process phosphoric acid production, meanwhile, a series of problems generated by the tailings are solved, the added value of the collophanite is increased, the negative influence on the environment is reduced, and a very good guiding effect is provided for development and utilization of the collophanite.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

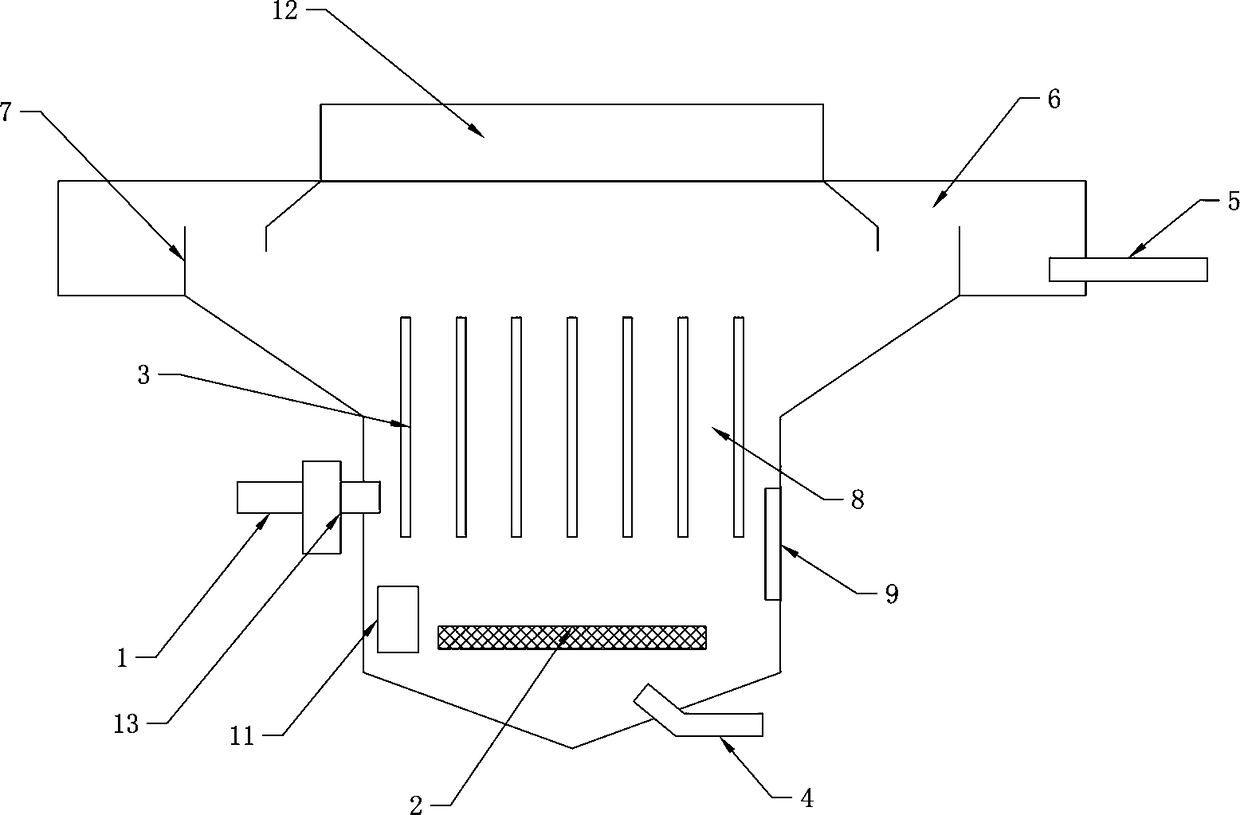

Phosphorus recycling integrated device for sludge digestion liquid and sludge filtrate

PendingCN108751529AAchieve recyclingLess impuritiesMultistage water/sewage treatmentWater/sewage treatment by degassingSludgeEngineering

The invention relates to the technical field of water treatment and relates to a phosphorus recycling integrated device for sludge digestion liquid and sludge filtrate and a method thereof. The sludgedigestion liquid and the sludge filter-press filtrate are pumped into a reactor by a water pump from a water inlet pipe; a phosphate ore crystallization zone, a sewage clarification zone and a sludgesedimentation zone are sequentially arranged in the reactor from top to bottom, a sludge discharging pipe is arranged at the bottom of the reactor, an aeration device is arranged on the reactor and above the sludge discharging pipe, and an ammonium magnesium phosphate crystallizing zone above the aeration device is provided with a stainless steel plate; a slope degree of an inclined face of an upper section of the reactor is 30 degrees to 60 degrees, the sewage clarification zone is arranged at the periphery of the upper section of the reactor, the periphery of the sewage clarification zone is communicated with a water outlet weir, the water outlet weir is communicated with a water outlet pipe, and liquid can be drained away through the water outlet pipe; the reactor is provided with an automatic chemical adding device and a pH meter.

Owner:广东正诚环境科技有限公司

Resource treatment method capable of reducing content of ammonia nitrogen, calcium ions and magnesium ions in manganese-containing wastewater

ActiveCN109851084APromotes the formation of precipitatesIncrease concentrationWater contaminantsMultistage water/sewage treatmentSolubilityResource recovery

The invention discloses a resource treatment method capable of reducing the content of ammonia nitrogen, calcium ions and magnesium ions in manganese-containing wastewater. The method comprises the steps: adding Mn(H2PO4)2.2H2O firstly, utilizing H2PO4<-> for ionization so as to obtain HPO4<2-> and PO4<3->, and performing reactions on the obtained HPO4<2-> and PO4<3-> with NH<4+> and Mg<2+> in themanganese-containing wastewater so as to produce ammonium magnesium phosphate precipitate, wherein the concentration of MnSO4 in the manganese-containing wastewater can be increased by Mn<2+> in Mn(H2PO4)2.2H2O, so that the repelling effect on CaSO4 is increased, and the solubility of CaSO4 is reduced; then adding MnSO4 so as to promote formation of CaSO4 precipitate and make Ca<2+> to precipitate in the form of CaSO4; and finally, introducing the manganese-containing wastewater through an adsorption material so as to achieve adsorption and collection of the remaining NH<4+>. Resource recovery of manganese, ammonia nitrogen and magnesium in the manganese-containing wastewater is achieved.

Owner:自然资源部天津海水淡化与综合利用研究所

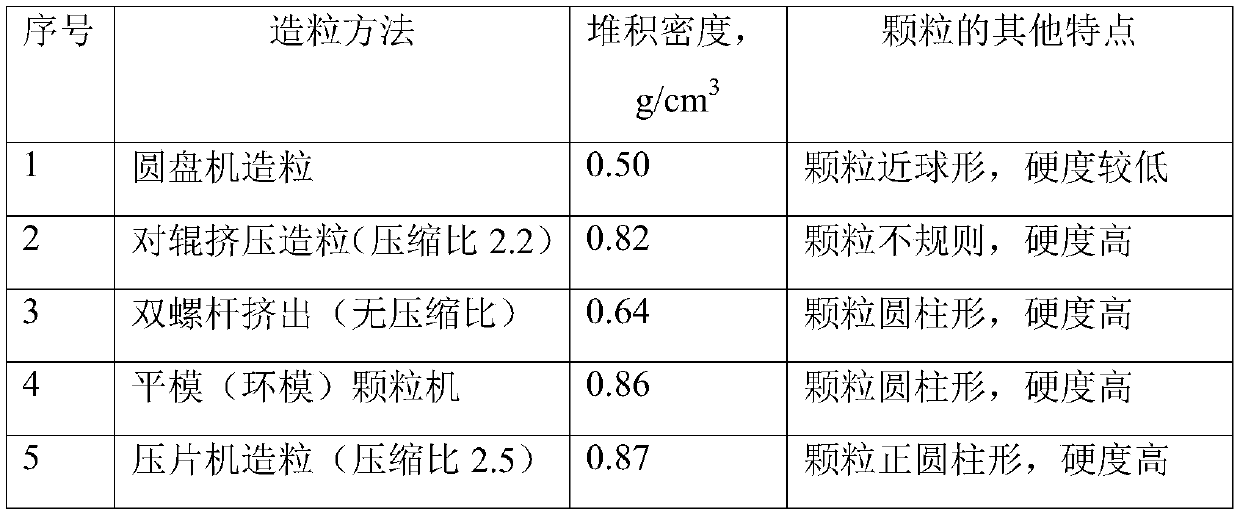

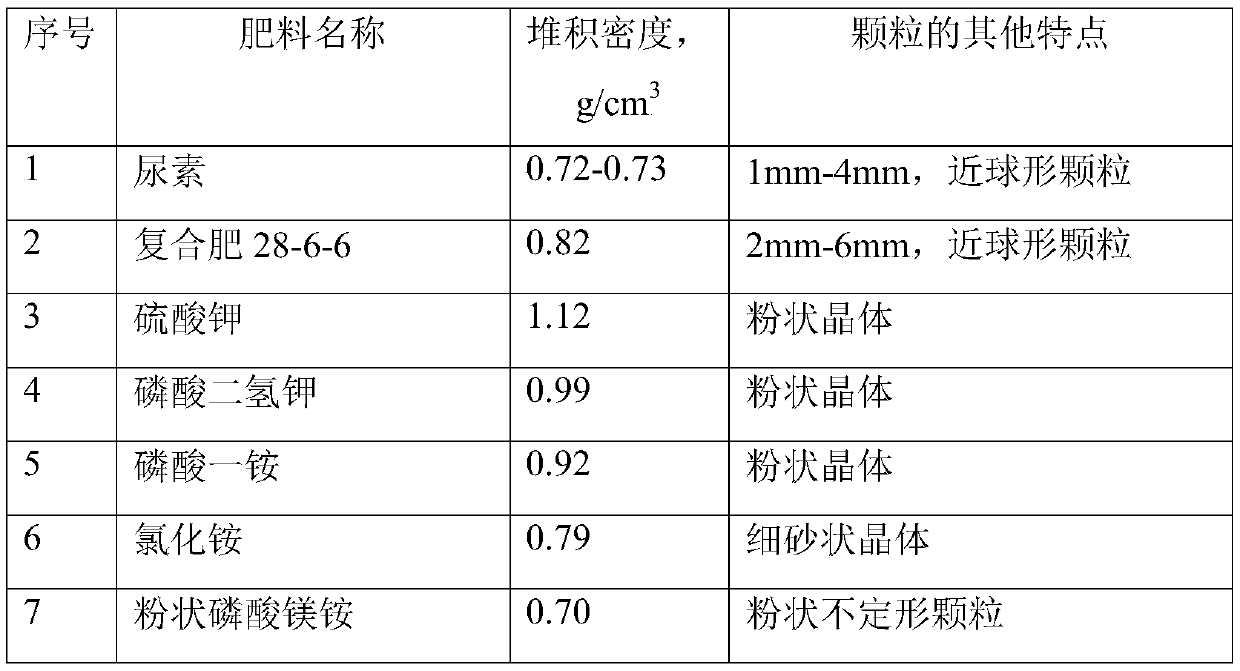

Ammonium magnesium phosphate particle not stratified when mixed and disintegrating in water and preparation method of ammonium magnesium phosphate particle

InactiveCN110372419ASolve the inability to disintegrate andSolve the problem of adequate soil mixingCalcareous fertilisersAlkali orthophosphate fertiliserDesiccantAdhesive

The invention discloses an ammonium magnesium phosphate particle not stratified when mixed and disintegrating in water and a preparation method of the ammonium magnesium phosphate particle, and belongs to the technical field of fertilizer manufacturing. According to the technical solution, the ammonium magnesium phosphate particleis prepared from the components: 90%-98% of ammonium magnesium phosphate, 1%-3% of a disintegrating agent, 1%-2% of a dispersant, 0%-2% of an adhesive and 0%-3% of a desiccant; and the stacking density of a particle is adjusted by granulation twice to obtain the2.0mm-4.0mm nearly spherical particle with the stacking density of 0.70g / cm<3>-0.75g / cm<3>,and thus the ammonium magnesium phosphate particle not stratified when mixed and disintegrating in water is obtained. According to the preparation method, by adding an auxiliary material into the ammonium magnesium phosphate and granulating twice,after mixing,no stratification of urea with the stacking density of0.72g / cm<3>-0.73g / cm<3>in a BB fertilizer is achieved, and the problem that ammonium magnesium phosphate particle cannot disintegrate and fully mix with soil in the moist environment is solved.

Owner:山东和生海洋科技有限公司

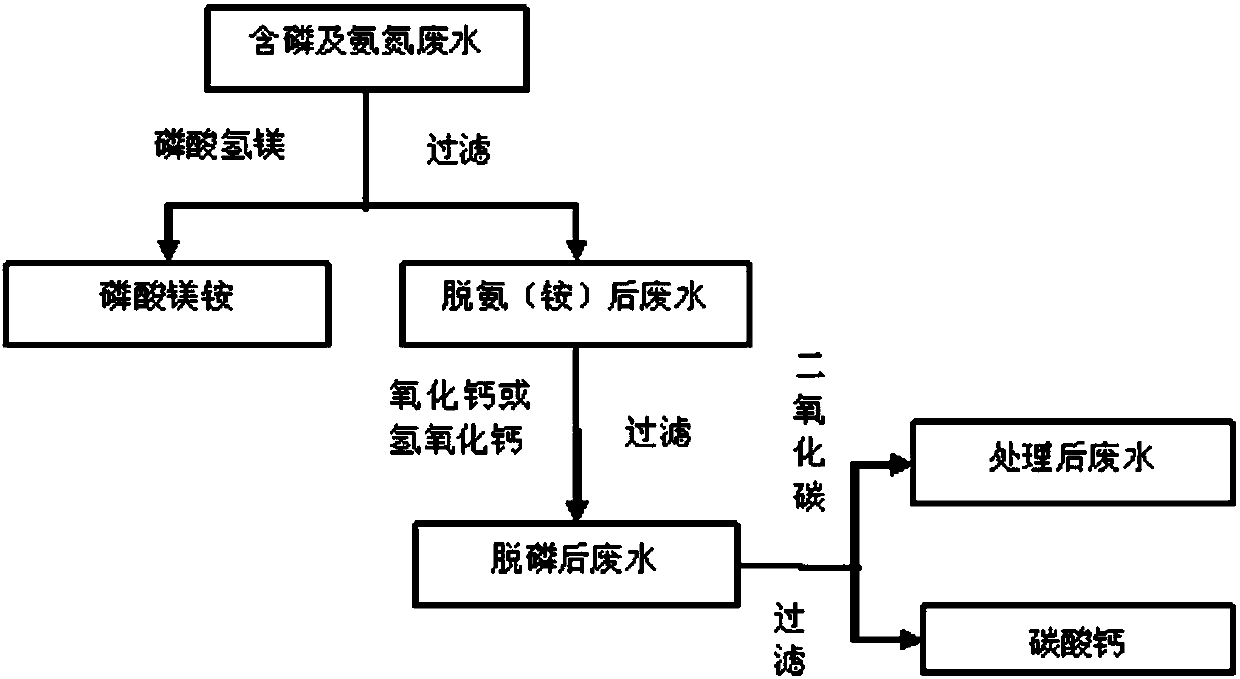

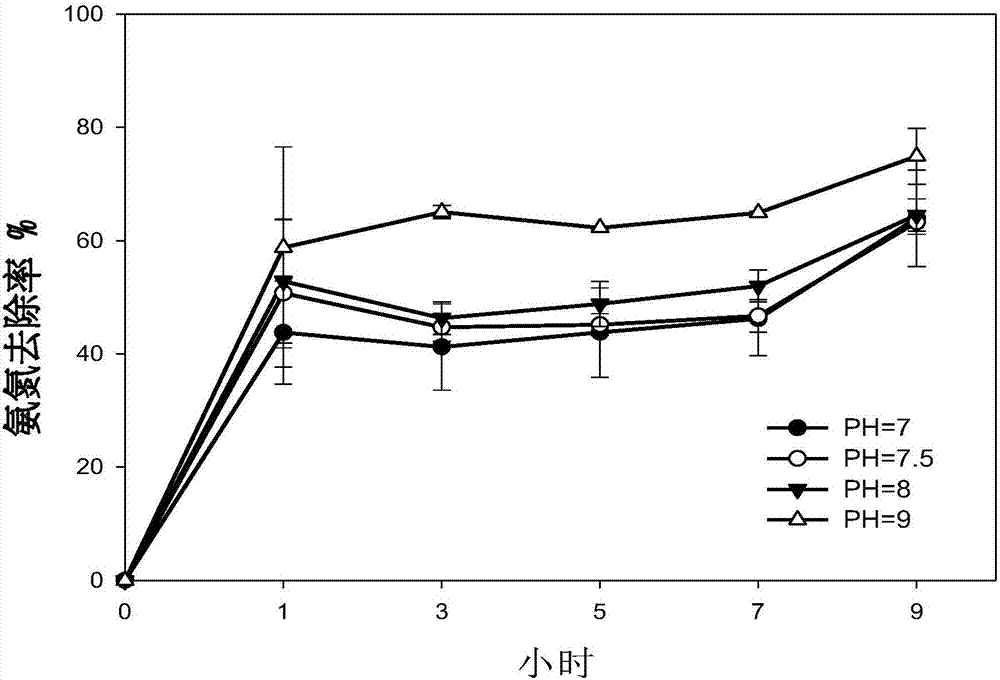

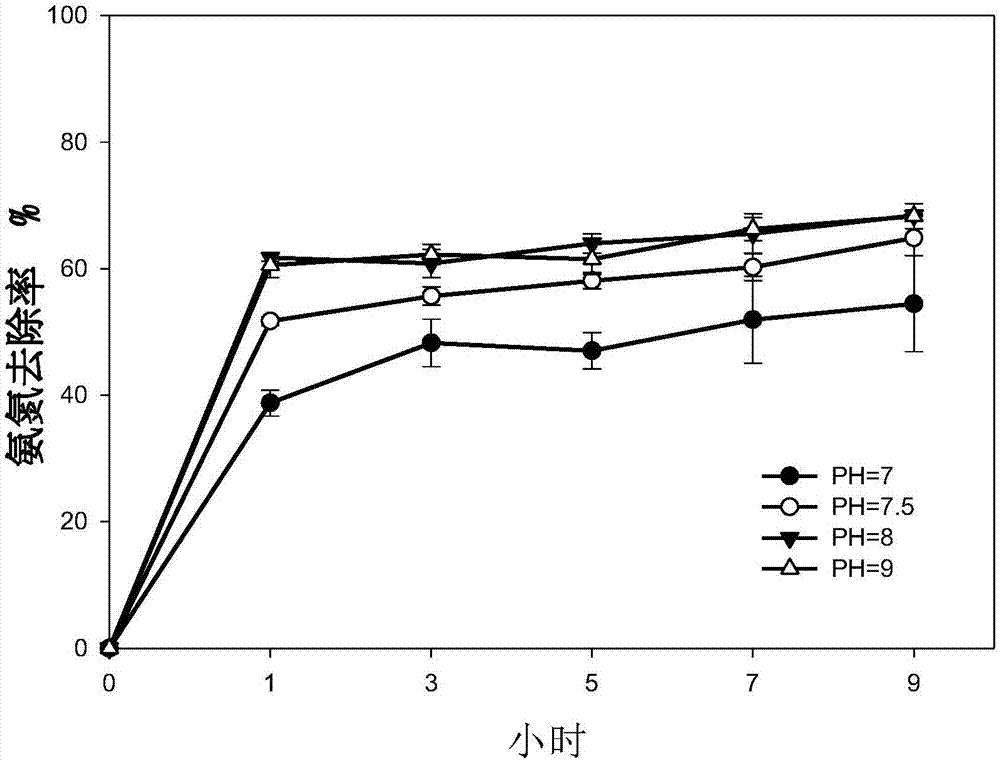

Phosphorus-containing and ammonia nitrogen wastewater treatment technology

InactiveCN107686192AEfficient removalRealize the allocation of local resourcesWater contaminantsMultistage water/sewage treatmentWater qualityTreated water

The invention provides a phosphorus-containing and ammonia nitrogen wastewater treatment technology. The phosphorus-containing and ammonia nitrogen wastewater treatment technology comprises the following steps: (1) adding magnesium hydrogen phosphate into phosphorus-containing and ammonia nitrogen wastewater to remove ammonia nitrogen, so as to obtain turbid liquid of ammonium magnesium phosphate;filtering and collecting ammonium magnesium phosphate sediment and filtrate I respectively; (2) adding lime into the filtrate I to remove phosphorus, so as to obtain turbid liquid containing calciumphosphate, magnesium hydroxide and less calcium hydroxide; filtering and collecting mixture sediment and filtrate II respectively; (3) introducing carbon dioxide into the filtrate II and removing residual calcium ions to obtain turbid liquid of calcium carbonate; filtering and collecting the calcium carbonate and filtrate III respectively, wherein the filtrate III is treated water without the phosphorus and the ammonia nitrogen. The phosphorus-containing and ammonia nitrogen wastewater treatment technology provided by the invention can be used for simultaneously and efficiently removing phosphorus and ammonia nitrogen harmful substances in the wastewater and the pH (Potential of Hydrogen) of the treated wastewater is nearly neutral; the content of the phosphorus is reduced to 1mg / L or lower and the content of the ammonia nitrogen is reduced to 25mg / L or lower; a valuable component ammonium magnesium phosphate is obtained; recycling preparation of a pollutant land is realized and the treated water quality is relatively good.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for eliminating ammonia inhibition in anaerobic fermentation process of livestock and poultry excrement

InactiveCN106865936AReduce consumptionRapid responseWaste water treatment from animal husbandryBiological sludge treatmentFecesVolatile fatty acids

The invention provides a method for eliminating ammonia inhibition in an anaerobic fermentation process of livestock and poultry excrement. According to the method, a struvite crystallization and sedimentation technology is used for detecting the concentration of NH<4+> in an ammonia inhibition system under the conditions that the pH value is 7-9, and the mass concentration ratio of volatile fatty acid to total inorganic carbon is less than 0.4; magnesium salt and phosphorus salt are added into a livestock and poultry excrement fermentation reaction system according to a molar ratio of the NH<4+> to Mg<2+> to PO4<3-> being equal to 1: 1: 1; the concentration of ammonia nitrogen is reduced to about a concentration value of the fermentation process without ammonia inhibition. The method for eliminating the ammonia inhibition in the anaerobic fermentation process of the livestock and poultry excrement is established by studying the influence factors of an ammonium magnesium phosphate reaction in the inner environment of an anaerobic fermentation tank and the self-limiting factors of the reaction. The method is simple in technology; furthermore, struvite precipitation produced in the reaction is slow release fertilizer, and not only can eliminate the ammonia nitrogen inhibition, but also can recover nutrients such as nitrogen and phosphorus, so that the operating cost is lowered.

Owner:CHINA AGRI UNIV

Garden controlled-release fertilizer and preparation method thereof

InactiveCN109265241ALong validity periodSlow structureCalcareous fertilisersMagnesium fertilisersAdhesiveAdditive ingredient

The invention discloses a garden controlled-release fertilizer which is prepared from compound fertilizer particles, an inhibitor layer, a microelement layer, an organic fertilizer layer and a controlled-release coating material layer, wherein the compound fertilizer particles are a compound fertilizer prepared from a plurality of fertilizers; the inhibitor layer is prepared from a urease inhibitor and a nitrification inhibitor; the microelement layer is prepared from industrial waste residues, tailing slag and attapulgite; the controlled-release coating material is prepared from ammonium magnesium phosphate and calcium carboxymethylcellulose. The controlled-release fertilizer is prepared from the following ingredients in parts by weight: 20 to 25 parts of urea, 10 to 15 parts of ammoniumphosphate, 10 to 15 parts of monopotassium phosphate, 15 to 20 parts of monoammonium phosphate, 5 to 10 parts of biochar, 5 to 10 parts of plant ash, 0.06 to 3 parts of inhibitor, 15 to 25 parts of microelements, 15 to 25 parts of organic fertilizer, 3 to 9 parts of controlled-release coating material and 2 to 6 parts of adhesive. The controlled-release fertilizer contains nitrogen, phosphorus andpotassium which are necessary to the plants, further contains microelements, can ensure that the quality and yield of plants are improved, can effectively inhibit nitrogen element loss, can improve soil tilth, has strong controlled-release capacity and water retention capacity and can prevent a soil structure from being damaged.

Owner:北京吉安奥德生物科技有限公司

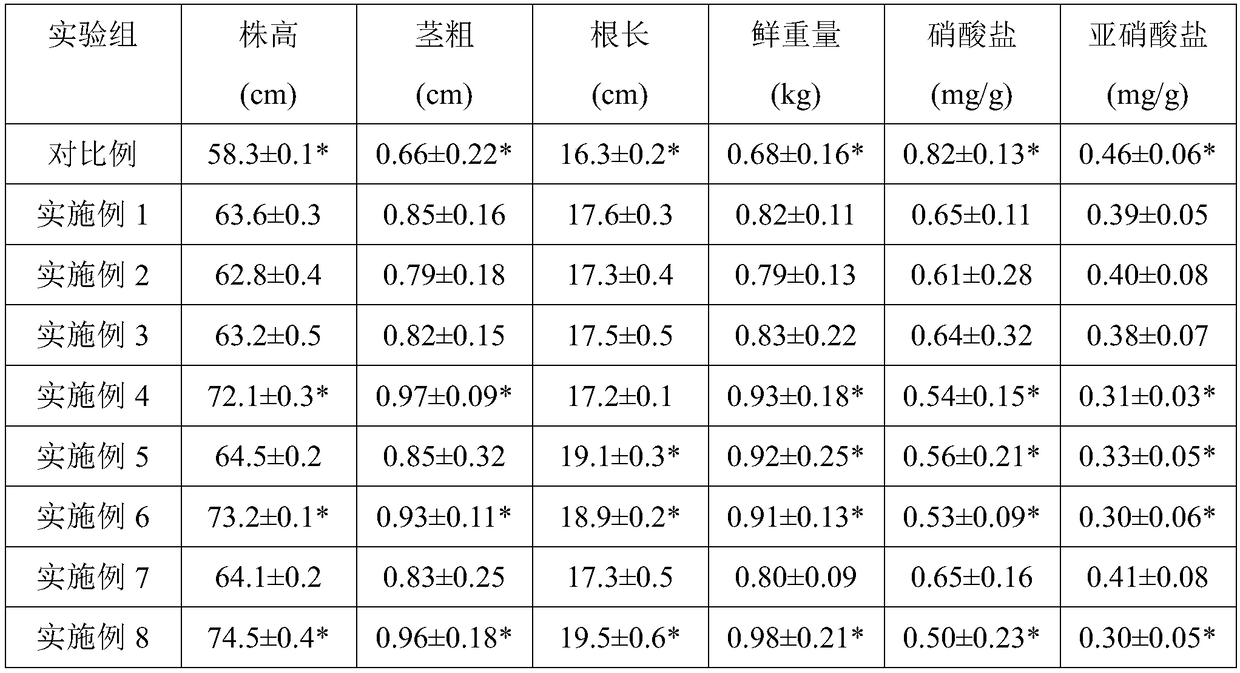

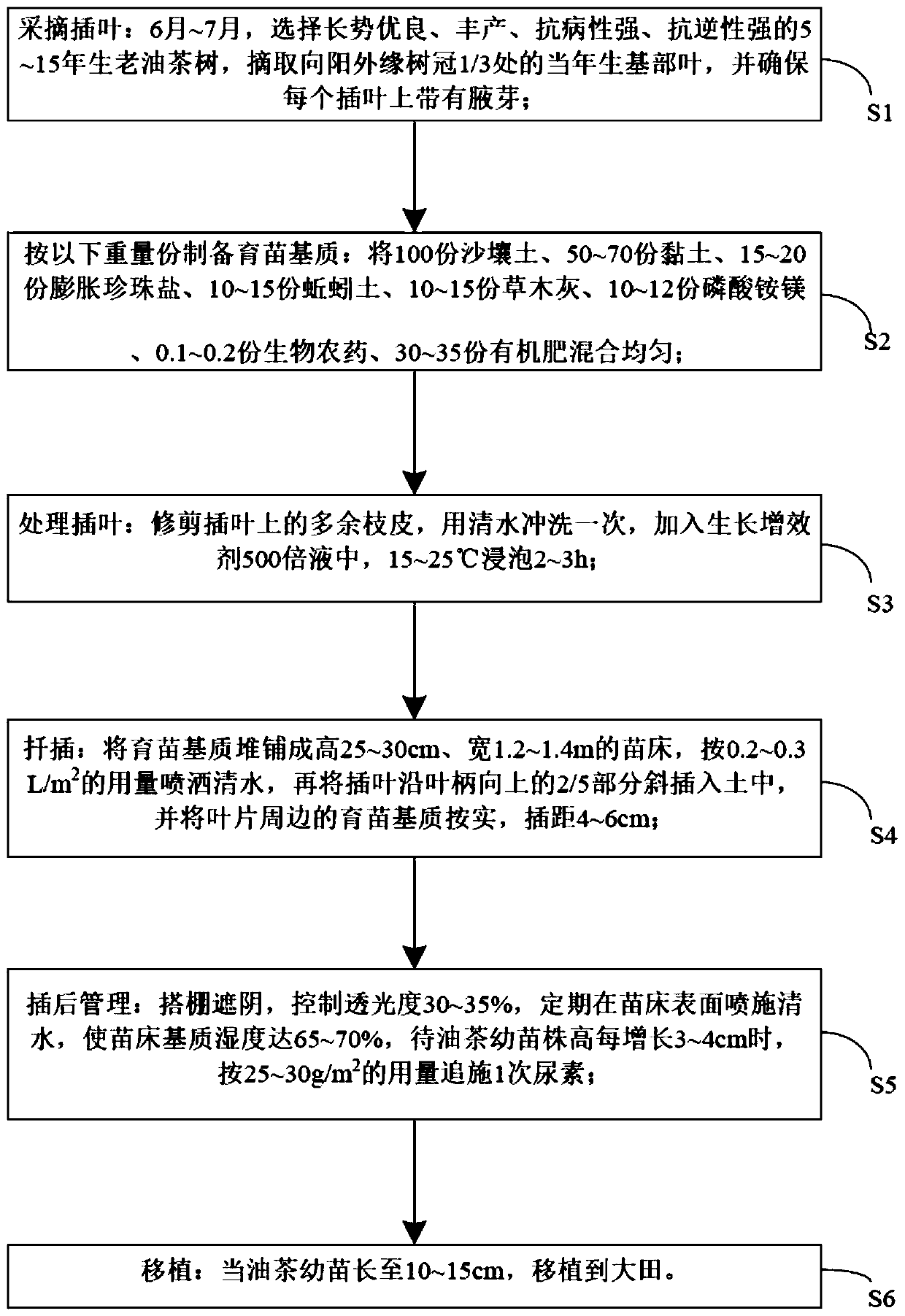

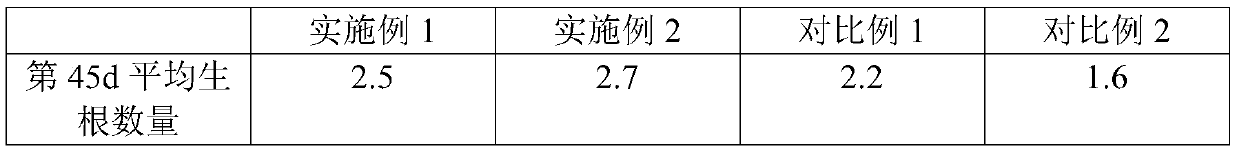

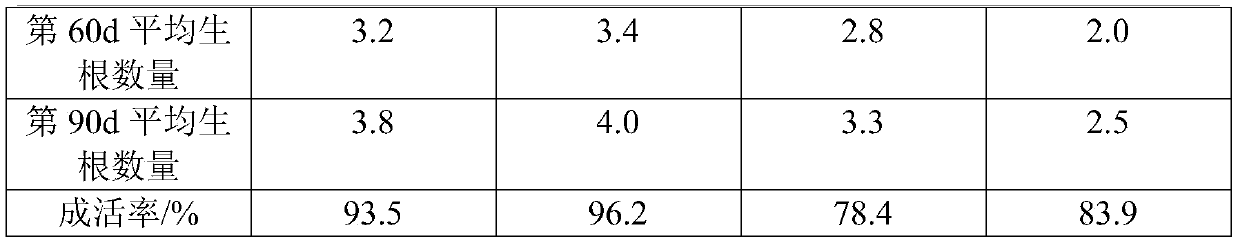

Seedling culture method for Camellia oleifera

InactiveCN110915520AImprove featuresGenetic stabilityBiocidePlant growth regulatorsBerberineCamellia oleifera

The invention discloses a seedling culture method for Camellia oleifera. The seedling culture method for Camellia oleifera comprises the following steps: (1) picking of cutting leaves; (2) preparationof a seedling culture substrate: mixing, in parts by weight, 100 parts of sandy loam, 50-70 parts of clay, 15-20 parts of expanded perlite, 10-15 parts of earthworm soil, 10-15 parts of plant ash, 10-12 parts of magnesium ammonium phosphate, 0.1-0.2 part of biological pesticide and 30-35 parts of organic fertilizer uniformly, wherein the biological pesticide comprises the following raw materials:in parts by weight, 4-8 parts of nano titanium oxide, 1-2 parts of Bacillus thuringiensis and 2-4 parts of Berberine; (3) treatment of the cutting leaves: adding the cutting leaves to a 500-fold growth enhancer solution, and performing soaking at 15-25 DEG C for 2-3 h; (4) cuttage; (5) management after cuttage: constructing a shed for sun shading, maintaining the humidity of the seedbed substrateat 65-70%, performing dressing of urea once at the dosage of 25-30 g / m<2> every time the plant height of Camellia oleifera seedlings is increased by 3-4 cm; and (6) transplantation. The cutting-leafseedling culturing method is adopted for vegetative propagation, excellent characteristics of mother Camellia oleifera trees can be maintained, stable inheritance and a high differentiation speed areachieved, and the survival rate of the cultured seedlings is 93.5% or above.

Owner:ANHUI YUMIN ECOLOGICAL AGRI

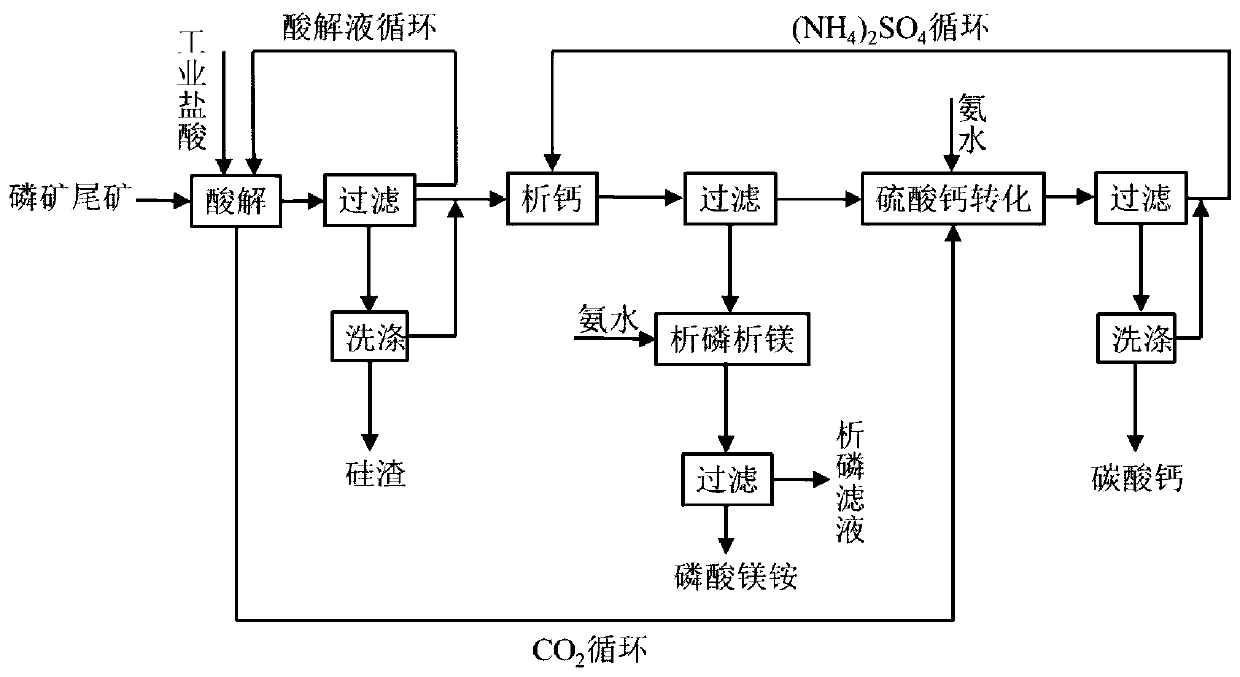

Method for preparing ammonium magnesium phosphate and CaCO3 from phosphate tailings and recycling byproducts (NH4) 2SO4 and CO2

PendingCN111498826AEfficient use ofIncrease added valueCalcium/strontium/barium carbonatesCarbon compoundsMagnesium phosphateMagnesium orthophosphate

The invention provides a method for preparing ammonium magnesium phosphate and CaCO3 from phosphate tailings and recycling byproducts (NH4) 2SO4 and CO2. The method comprises the following steps: performing acidolysis on the phosphate tailings; then, mixing a mixed acidolysis solution obtained by acidolysis with an ammonium sulfate solution; performing calcium separation reactions, and obtaining calcium sulfate and calcium precipitation mother liquor, wherein calcium sulfate and ammonia water are prepared into calcium sulfate slurry, CO2 generated by acidolysis reaction is introduced for carbonization reaction to obtain calcium carbonate and an ammonium sulfate solution, and the obtained ammonium sulfate solution can be circularly added into the mixed acidolysis solution for cyclic calciumprecipitation reaction; and finally, neutralizing the calcium precipitation mother solution by ammonia water and subjecting to phosphorus precipitation reaction to obtain ammonium magnesium phosphate. According to the invention, valuable elements in the high-magnesium phosphate tailings can be effectively utilized, wherein the recovery rates of calcium and phosphorus elements in the phosphate tailings reach 95% or above, the contents of effective components P2O5, MgO and total nitrogen in ammonium magnesium phosphate can reach 28%, 18% and 9% or above respectively, the purity of calcium carbonate reaches 97% or above, and the quality meets the qualified product requirements in the standard HG2226-91.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

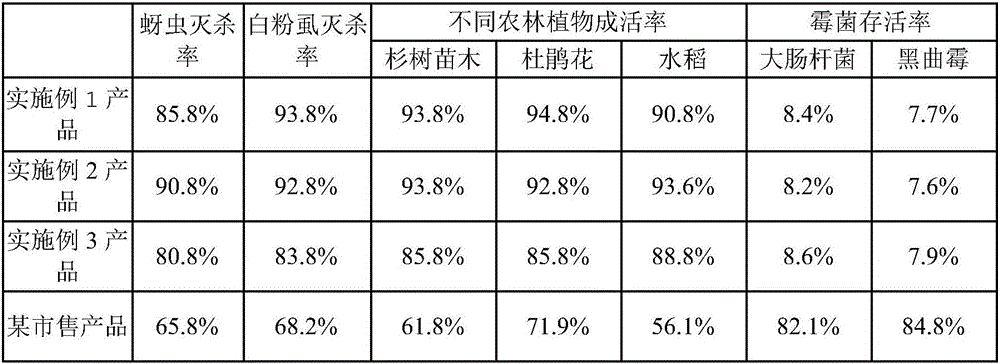

Antimicrobial pesticidal slow-release ecological fertilizer for agriculture and forestry

InactiveCN106747963AIncrease supplyImprove survival rateCalcareous fertilisersDi-calcium phosphate fertilisersBenzoic acidChelated zinc

The invention relates to an antimicrobial pesticidal slow-release ecological fertilizer for agriculture and forestry. The fertilizer is composed of ammonium sulfate, a potassium sulfate magnesium fertilizer, lutein ester, a potassium silicon fertilizer, potassium polyaspartate, oyster shell powder, deer manure, wormcast, duck manure, bean pulp, Chinese cabbage residues, Mepigtlat-chloride, sodium humate, squalene, forchlorfenuron, azone, amino acid chelated calcium, amino acid chelated zinc, copper oxide powder, calcium hydrogen phosphate dihydrate, ammonium magnesium phosphate, cupric nitrate powder, calcium sulfate powder, expanded vermiculite powder, sulfur powder powder, 2-(acetoxy)benzoic acid, ricinine, pepper powder, reglox, arabic gum, dimercaptopropanol, fermented vinegar, potassium fluozirconate and erythritol. The product has the advantages of simple preparation technique, excellent soil restoration capability and favorable pesticidal property, and is beneficial to supplying required nutrient elements to agriculture and forestry crops, thereby greatly enhancing the survival percent of planted agriculture and forestry crops and improving the use effect.

Owner:马鞍山三立生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com