Method for preparing ammonium magnesium phosphate and CaCO3 from phosphate tailings and recycling byproducts (NH4) 2SO4 and CO2

A magnesium ammonium phosphate and 2SO4 technology, which is applied in the field of waste resource utilization, can solve the problems of low added value of products and low utilization rate of phosphorus tailings, and achieve the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 6.24%, MgO: 13.8%, CaO: 31.91%, SiO 2 : 7.75%.

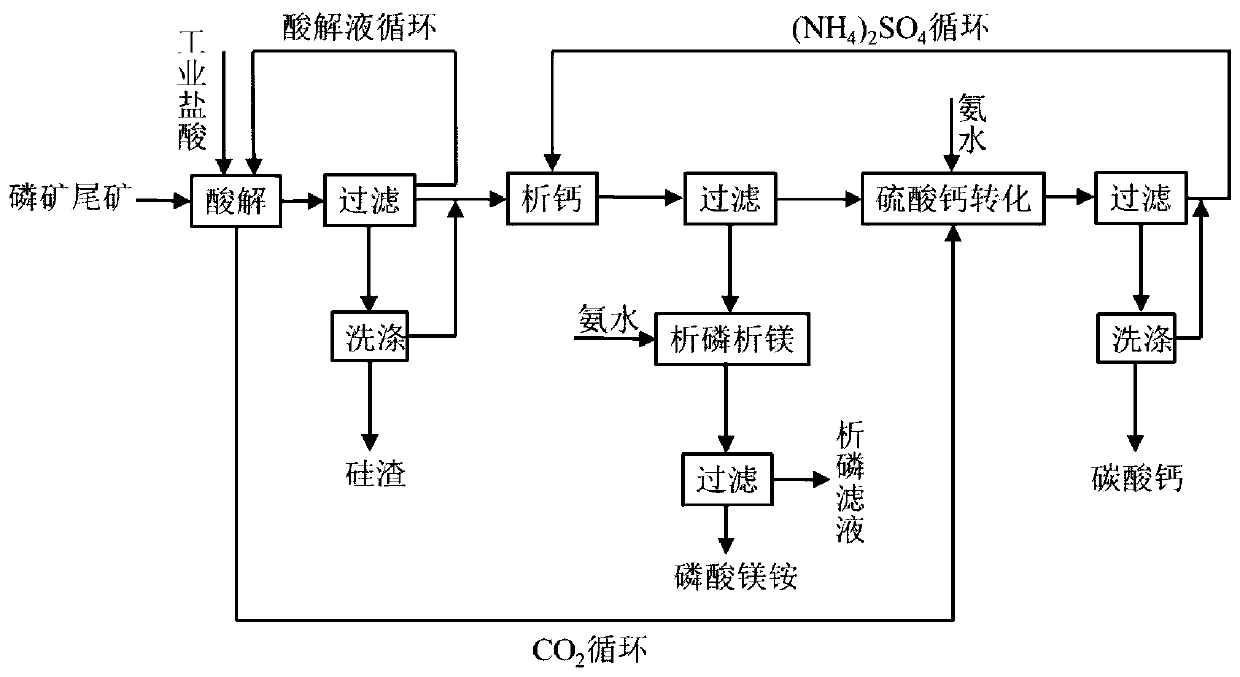

[0033] combine figure 1 Shown, the phosphorous tailings of present embodiment prepare magnesium ammonium phosphate and CaCO 3 and recycle by-products (NH 4 ) 2 SO 4 and CO 2 method, specifically including the following steps:

[0034] 1) Measure 232mL tap water and 232mL of mass fraction respectively and be 35% industrial hydrochloric acid (9.98mol / L) to be placed in the same clean three-necked flask, according to the mole of calcium and magnesium in industrial hydrochloric acid and high-magnesium phosphorus tailings 2.54:1 Take 100g of high-magnesium phosphorus tailings, gradually add high-magnesium phosphorus tailings into the three-necked flask, and simultaneously put the produced CO 2 Introduce the gas into the carbonization reactor in step 4), stir at 50°C, and after acidolysis for 30 minutes, heat-preserve and filter to obtai...

Embodiment 2

[0040] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 7.35%, MgO: 11.8%, CaO: 33.22%, SiO 2 : 8.67%.

[0041] to combine figure 1 Shown, the phosphorous tailings of present embodiment prepare magnesium ammonium phosphate and CaCO 3 and recycle by-products (NH 4 ) 2 SO 4 and CO 2 method, specifically including the following steps:

[0042] 1) Measure 200mL tap water and 232mL mass fraction respectively and be 35% industrial hydrochloric acid (9.98mol / L) to be placed in the same clean three-necked flask, according to the mole of calcium and magnesium in industrial hydrochloric acid and high-magnesium phosphorus tailings 2.9:1 Take 90g of high-magnesium phosphorus tailings, gradually add high-magnesium phosphorus tailings into the three-necked flask, and simultaneously remove the produced CO 2 Introduce the gas into the carbonization reactor in step 4), stir at 60°C, and after acidolysis for 30 minutes, heat-preserve and filter to obta...

Embodiment 3

[0048] In an embodiment, the raw ore chemical composition of phosphate rock is: P 2 o 5 : 9.5%, MgO: 14.5%, CaO: 38.26%, SiO 2 : 7.35%.

[0049] to combine figure 1 Shown, the phosphorous tailings of present embodiment prepare magnesium ammonium phosphate and CaCO 3 and recycle by-products (NH 4 ) 2 SO 4 and CO 2 method, specifically including the following steps:

[0050] 1) Measure 150mL of tap water and 232mL of mass fraction respectively and be 35% industrial hydrochloric acid (9.98mol / L) to be placed in the same clean three-necked flask. Take 65g of high-magnesium phosphorus tailings, gradually add high-magnesium phosphorus tailings into the three-necked flask, and simultaneously 2 Introduce the gas into the carbonization reactor in step 4), stir at 70°C, and after acidolysis for 30 minutes, heat-preserve and filter to obtain the acidolysis solution and silicon slag, and measure 80 mL according to the mass ratio of the total mass of washing water to the silicon s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com