Garden controlled-release fertilizer and preparation method thereof

A slow-release fertilizer and gardening technology, applied in the direction of organic fertilizers, inorganic fertilizers, calcium fertilizers, etc., can solve the problems of unreasonable application of chemical fertilizers, reduced slow-release capacity, flammability, etc., to ensure plant quality and yield increase, slow Strong release ability and water retention ability, and the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

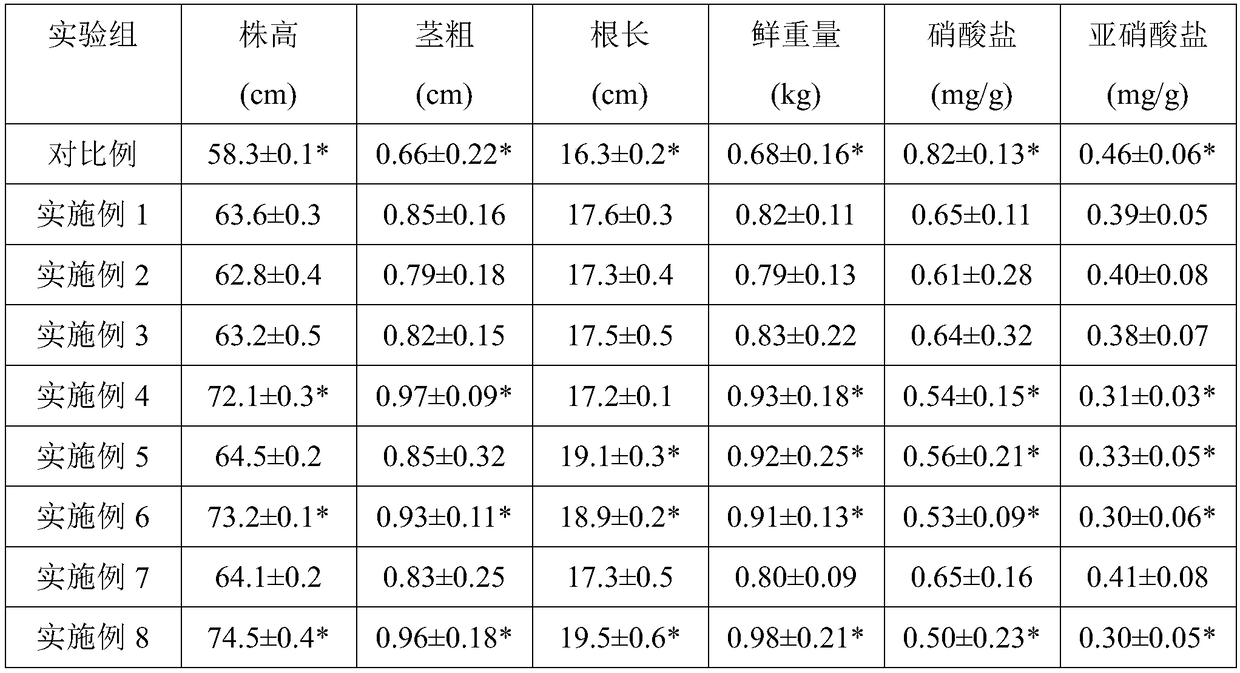

Examples

Embodiment 1

[0027] A garden slow-release fertilizer, comprising the following raw materials in parts by weight: urea 22.5kg, ammonium phosphate 12.5kg, potassium dihydrogen phosphate 12.5kg, ammonium dihydrogen phosphate 17.5kg, biochar 7.5kg, plant ash 7.5kg, N- Butylthiophosphoric triamide 0.5kg, 2-chloro-6-trichloromethylpyridine 1kg, manganese slag 8kg, borate tailings slag 8kg, attapulgite 4kg, ammoniated peat 3kg, weathered coal 3kg, peat 4kg , seaweed 4kg, leguminous plant straw 6kg, magnesium ammonium phosphate 2kg, carboxymethyl cellulose calcium 4kg, polyvinyl alcohol solution 4kg.

[0028] The preparation method of the above-mentioned slow-release fertilizer for gardens is carried out according to the following steps:

[0029] (1) Compound fertilizer granulation: put 22.5kg of urea, 12.5kg of ammonium phosphate, 12.5kg of potassium dihydrogen phosphate, 17.5kg of ammonium dihydrogen phosphate, 7.5kg of biochar, and 7.5kg of plant ash into the ball mill according to the parts by...

Embodiment 2

[0035] A slow-release fertilizer for gardens, comprising the following raw materials in parts by weight: urea 20kg, ammonium phosphate 10kg, potassium dihydrogen phosphate 10kg, ammonium dihydrogen phosphate 15kg, biochar 5kg, plant ash 5kg, N-butyl phosphorothioate Triamine 0.02kg, 2-chloro-6-trichloromethylpyridine 0.04kg, zinc slag 6kg, magnesium iron silicate tailings slag 6kg, attapulgite 3kg, ammoniated peat 2kg, weathered coal 2kg, peat 3kg, Seaweed 3kg, legume straw 5kg, magnesium ammonium phosphate 1kg, carboxymethyl cellulose calcium 2kg, polyvinyl alcohol solution 2kg.

[0036] The preparation method of the above-mentioned slow-release fertilizer for gardens is carried out according to the following steps:

[0037] (1) Compound fertilizer granulation: According to parts by weight, 20kg of urea, 10kg of ammonium phosphate, 10kg of potassium dihydrogen phosphate, 15kg of ammonium dihydrogen phosphate, 5kg of biochar, and 5kg of plant ash were put into a ball mill for ...

Embodiment 3

[0043] A garden slow-release fertilizer, comprising the following raw materials in parts by weight: urea 25kg, ammonium phosphate 15kg, potassium dihydrogen phosphate 15kg, ammonium dihydrogen phosphate 20kg, biochar 10kg, plant ash 10kg, N-butyl phosphorothioate Triamine 1kg, 2-chloro-6-trichloromethylpyridine 2kg, zinc slag 10kg, magnesium iron silicate tailings slag 10kg, attapulgite 5kg, ammoniated peat 4kg, weathered coal 4kg, peat 5kg, seaweed 5kg 1. Legume straw 7kg, magnesium ammonium phosphate 3kg, carboxymethylcellulose calcium 6kg, polyvinyl alcohol solution 6kg.

[0044] The preparation method of the above-mentioned slow-release fertilizer for gardens is carried out according to the following steps:

[0045] (1) Compound fertilizer granulation: according to parts by weight, 25kg of urea, 15kg of ammonium phosphate, 15kg of potassium dihydrogen phosphate, 20kg of ammonium dihydrogen phosphate, 10kg of biochar, and 10kg of plant ash were put into a ball mill for dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com