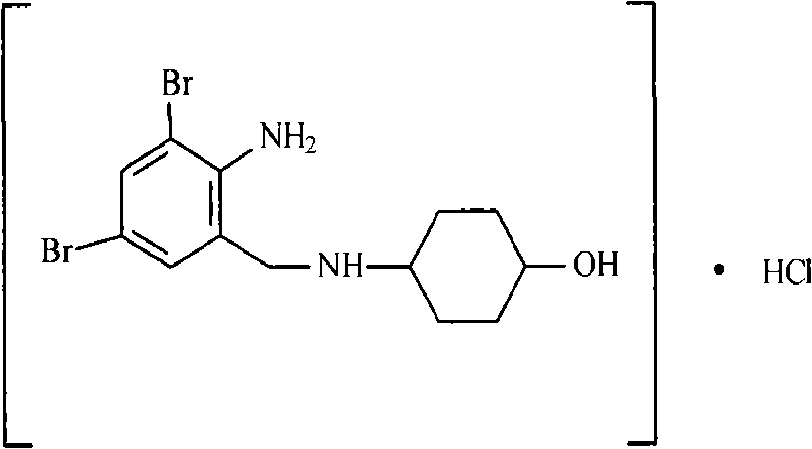

Method for refining injection-level ambroxol hydrochloride, product and injection thereof

A technology of ambroxol hydrochloride and refining method, which is applied in the field of refining and purification of ambroxol hydrochloride crude drug, to achieve the effects of improving quality, refining process safety, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

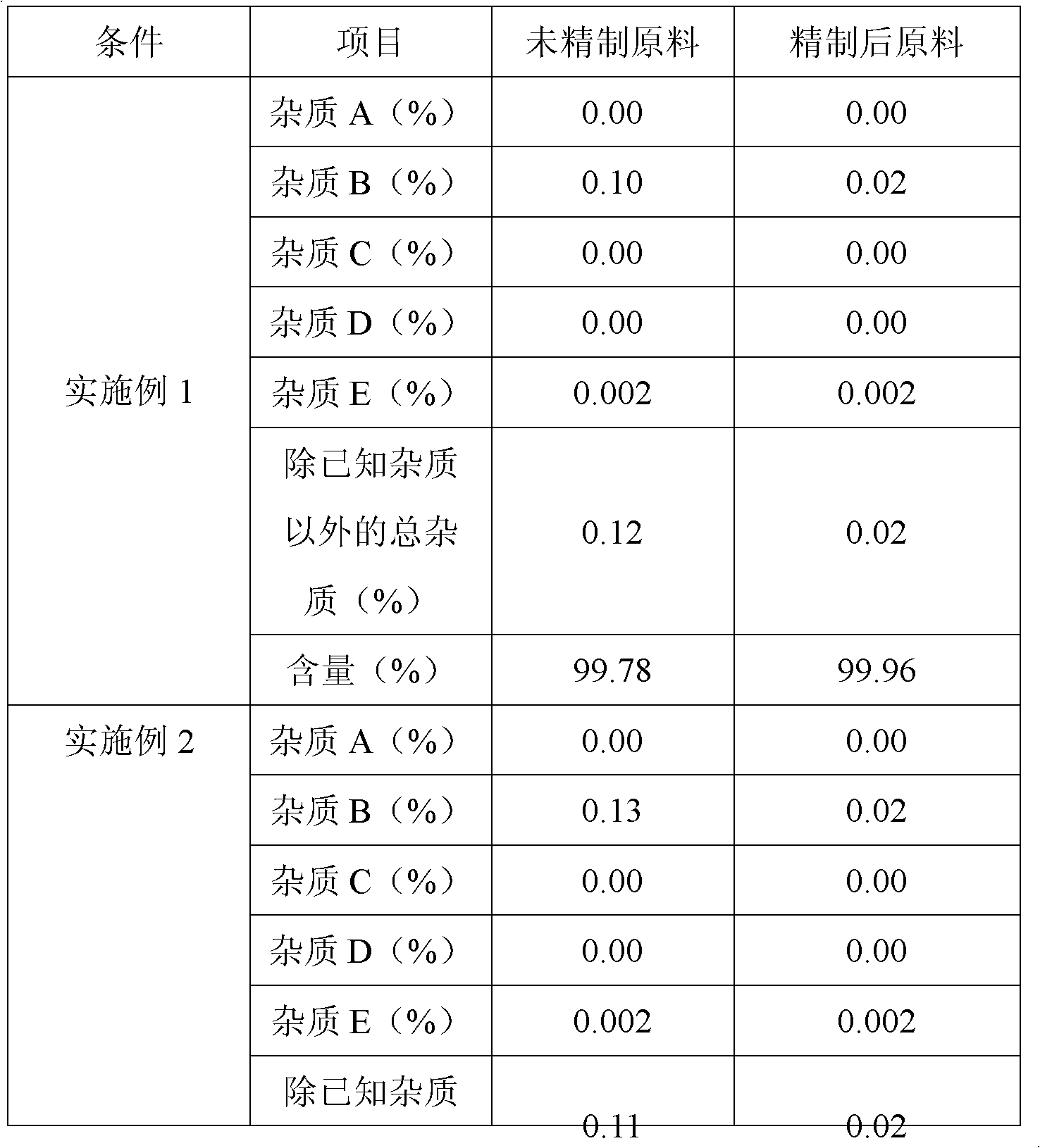

Examples

Embodiment 1

[0026] injection grade ambroxol hydrochloride refining method, get the ambroxol hydrochloride raw material 100g that purity is 99.78%, slowly add the aqueous ethanol solution of 550ml88% under stirring, be heated to 80-85 ℃ after back distillation 20 minutes, Ambroxol hydrochloride is completely dissolved in the solvent; stop heating, place it at 6-8°C for 4 hours and then crystallize; filter off the solvent to obtain crystals, dry at 80°C for 4-8 hours, take out and weigh. With 79g of the refined ambroxol hydrochloride raw material in this step, slowly add 435ml of 88% ethanol aqueous solution under stirring; after heating to 60-65° C. in a water bath for 60 minutes, ambroxol hydrochloride is completely dissolved in the solvent; Stop heating, place at 6-8°C for 4 hours and crystallize out; filter off the solvent to obtain crystals, dry at 80°C for 4-8 hours, then take out.

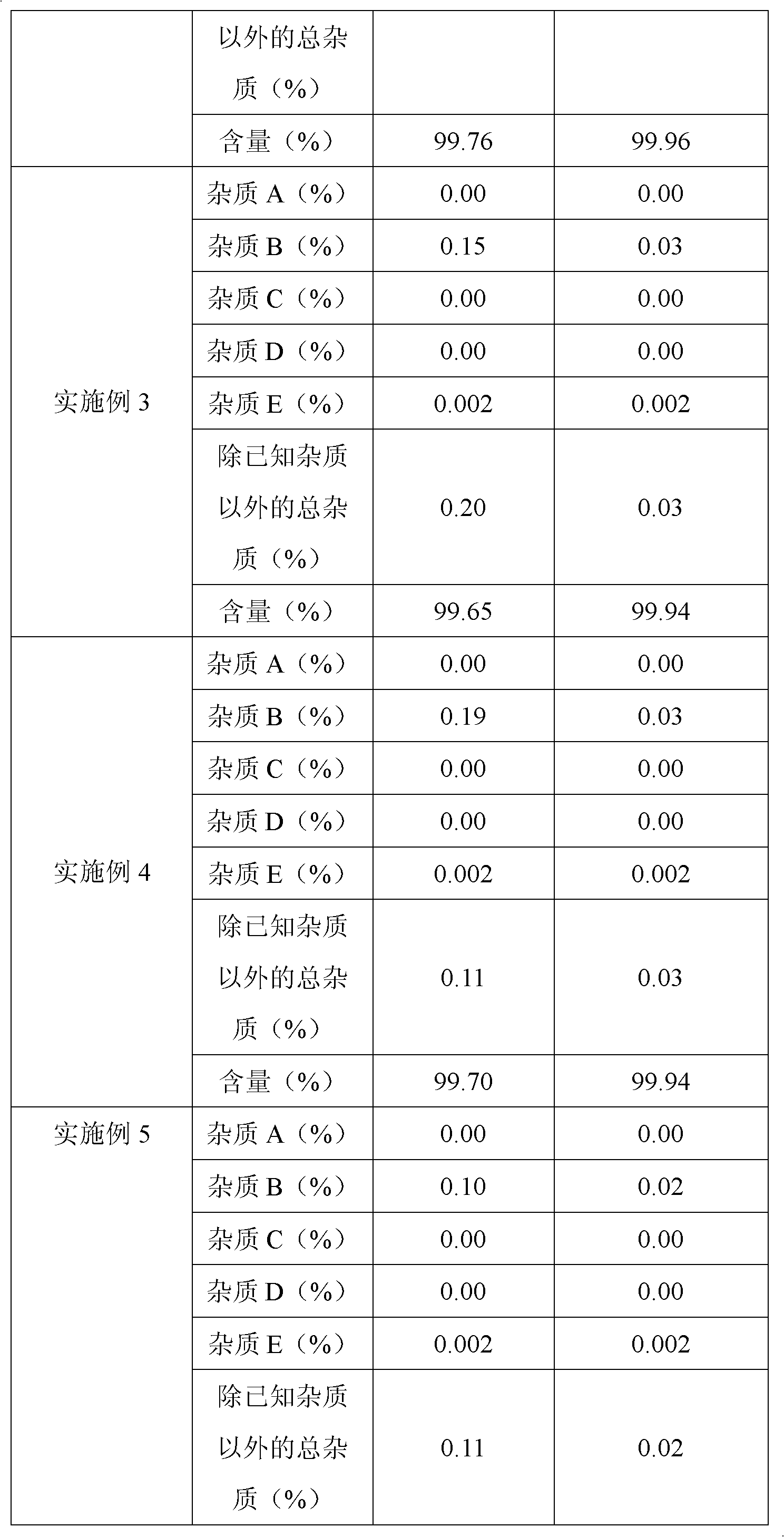

Embodiment 2

[0027] injection grade ambroxol hydrochloride refining method, get the ambroxol hydrochloride raw material 100g that purity is 99.76%, slowly add the aqueous ethanol solution of 550ml88% under stirring, after heating in 85-90 ℃ of water baths 30 minutes, Ambroxol hydrochloride is completely dissolved in the solvent; stop heating, place it at 3-5°C for 4 hours and then crystallize; filter off the solvent to obtain crystals, dry at 80°C for 4-8 hours, and then take it out.

Embodiment 3

[0028] Injection grade ambroxol hydrochloride refining method, get the ambroxol hydrochloride crude drug 100g that purity is 99.65%, slowly add the ethanol aqueous solution of 760ml81% under stirring, be heated to 85-90 ℃ after back distillation 30 minutes , Ambroxol hydrochloride is completely dissolved in the solvent; stop heating, place it at 6-8°C for 4 hours and then crystallize; filter off the solvent to obtain crystals, dry at 80°C for 4-8 hours, and then take it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com