Phosphorus-containing and ammonia nitrogen wastewater treatment technology

An ammonia nitrogen wastewater treatment technology, applied in the field of environmental chemistry, can solve the problems of poor nitrogen and phosphorus comprehensive efficiency, high removal rate, limited application pH range, etc., and achieve the effect of good water quality and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

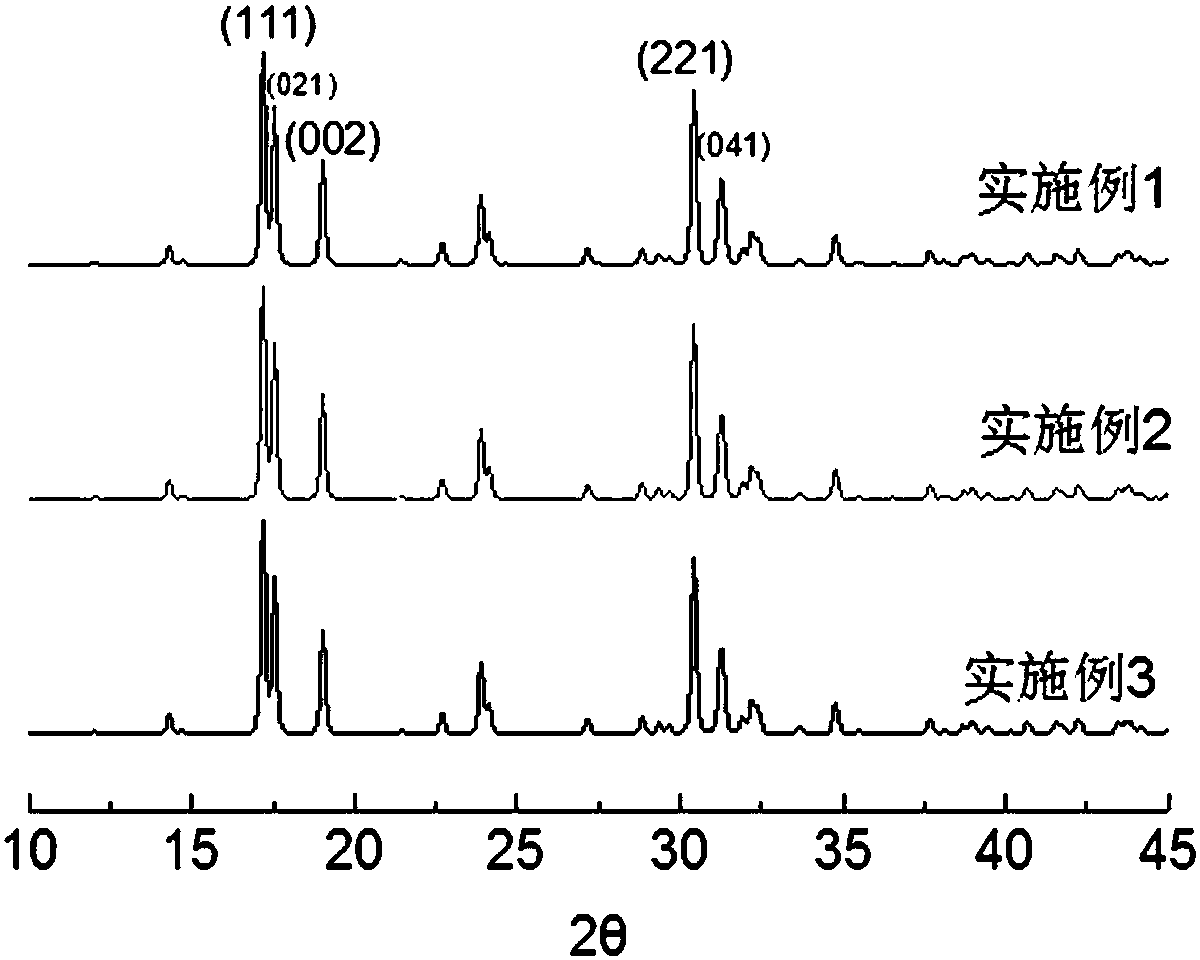

Embodiment 1

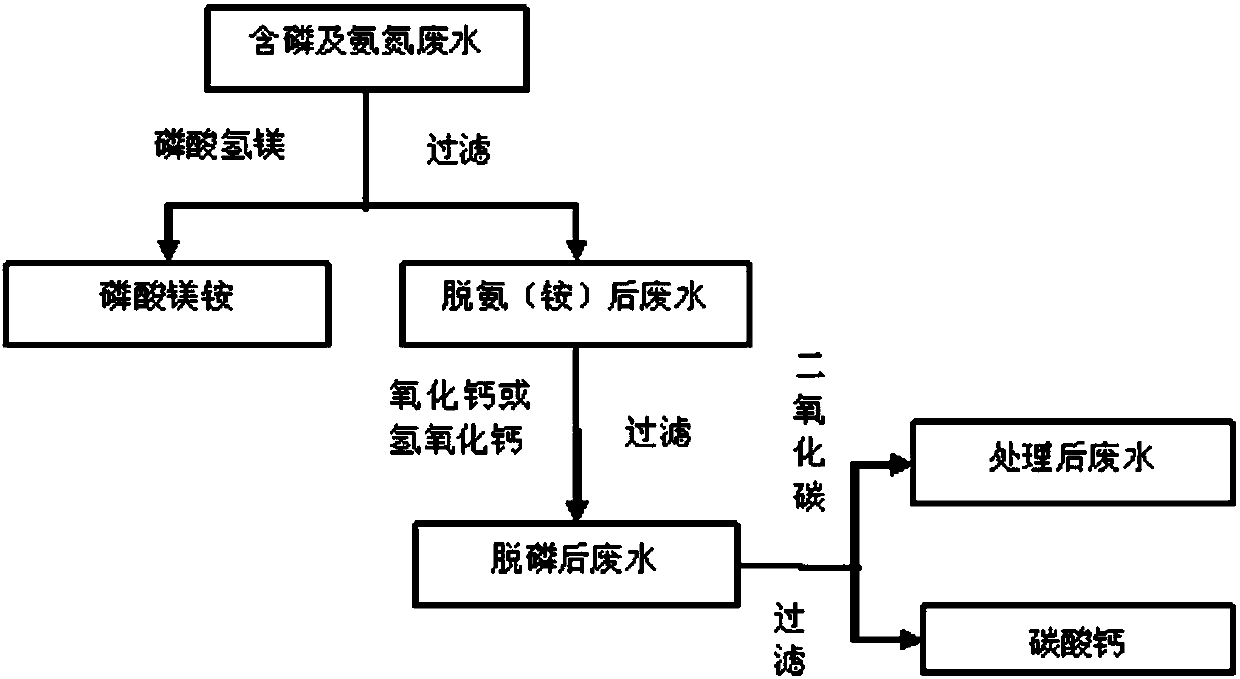

[0030] Phosphorus and ammonia nitrogen-containing wastewater contains 360mg / L of ammonia nitrogen (equivalent to N content), phosphorus content of 560mg / L (equivalent to P content), and pH of 5.7. This process is used to treat the wastewater with a treatment capacity of 100L. Process flow chart Such as figure 1 shown, including the following steps:

[0031] (1) Add magnesium hydrogen phosphate trihydrate to remove ammonia nitrogen in phosphorus and ammonia nitrogen wastewater, wherein the addition amount of magnesium hydrogen phosphate trihydrate is: the molar ratio of magnesium hydrogen phosphate trihydrate and ammonia nitrogen ion is 1.2: 1, and the reaction time is 2h, stirring rate is 600rpm, obtain the suspension of magnesium ammonium phosphate, filter, collect magnesium ammonium phosphate precipitation and filtrate one respectively;

[0032] (2) Add slaked lime to remove phosphorus in filtrate one, wherein the addition amount of lime is: the molar ratio of calcium eleme...

Embodiment 2

[0035] Phosphorus and ammonia nitrogen-containing wastewater contains 175mg / L of ammonia nitrogen (equivalent to N content), phosphorus content of 230mg / L (equivalent to P content), and pH of 7.6. This process is used to treat the wastewater with a treatment capacity of 500L. Process flow chart Such as figure 1 shown, including the following steps:

[0036] (1) Add magnesium hydrogen phosphate trihydrate to remove ammonia nitrogen in wastewater containing phosphorus and ammonia nitrogen, wherein the addition amount of magnesium hydrogen phosphate trihydrate is: the mol ratio of magnesium hydrogen phosphate trihydrate and ammonia nitrogen ion is 2.1: 1, and the reaction time is 1.5h, stirring rate is 200rpm, obtain the suspension of magnesium ammonium phosphate, filter, collect magnesium ammonium phosphate precipitation and filtrate one respectively;

[0037] (2) add slaked lime to remove phosphorus in filtrate one, wherein the addition amount of lime is: the mol ratio of calc...

Embodiment 3

[0040] Phosphorous and ammonia nitrogen containing wastewater contains 85mg / L of ammonia nitrogen (equivalent to N content), phosphorus content of 97mg / L (equivalent to P content), and pH of 8.7. This process is used to treat the waste water with a treatment capacity of 1T. Process flow chart Such as figure 1 shown, including the following steps:

[0041](1) Add magnesium hydrogen phosphate trihydrate to remove ammonia nitrogen in wastewater containing phosphorus and ammonia nitrogen, wherein the addition amount of magnesium hydrogen phosphate trihydrate is: the molar ratio of magnesium hydrogen phosphate trihydrate and ammonia nitrogen ion is 2.5: 1, and the reaction time is 1h, stirring rate is 480rpm, obtains the suspension of magnesium ammonium phosphate, filters, and collects magnesium ammonium phosphate precipitation and filtrate one respectively;

[0042] (2) add slaked lime to remove phosphorus in filtrate one, wherein the addition amount of lime is: the mol ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com