Degradable slow release fertilizer containing magnesium sulfate and preparing method thereof

A technology of magnesium sulfate and slow-release fertilizer, which is applied in the field of degradable slow-release fertilizer containing magnesium sulfate and its preparation, can solve the problems of non-degradable coating material, eutrophication of water body, secondary pollution of the environment, etc. The effect of water retention capacity, growth promotion, and soil environment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

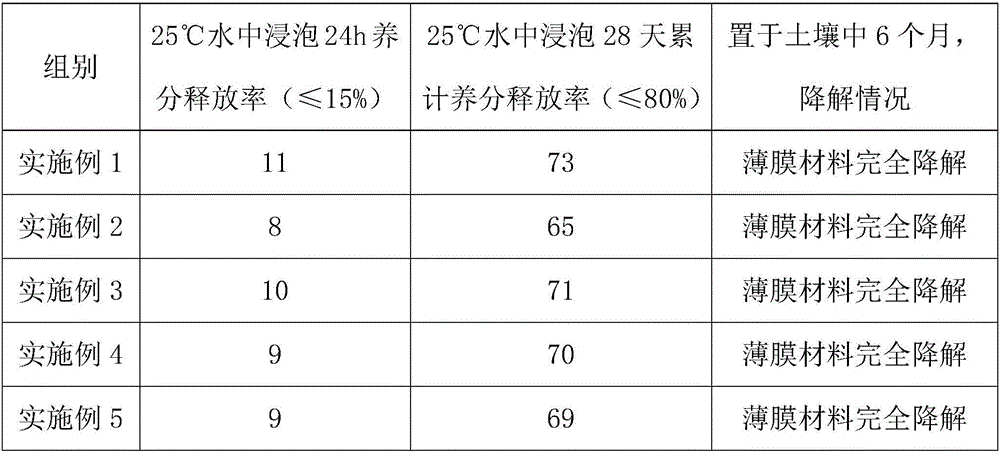

Examples

Embodiment 1

[0018] A degradable slow-release fertilizer containing magnesium sulfate, its raw materials include by weight: 15 parts of potassium phosphate, 15 parts of ammonium nitrate, 11 parts of ammonium dihydrogen phosphate, 7 parts of potassium nitrate, 13 parts of urea, and 0.45 parts of ammonium magnesium phosphate , 0.3 parts of zinc sulfate, 0.3 parts of magnesium sulfate, 0.25 parts of ferric chloride, 0.15 parts of manganese sulfate, 12 parts of biochar, 7 parts of humic acid, and 35 parts of coating materials.

[0019] The preparation method of the above-mentioned degradable slow-release fertilizer containing magnesium sulfate comprises the following steps: spraying atomized water to the urea to make the surface of the urea wet, adding potassium phosphate, ammonium nitrate, ammonium dihydrogen phosphate, potassium nitrate, ammonium magnesium phosphate, sulfuric acid Mix zinc, magnesium sulfate, ferric chloride, manganese sulfate, biochar, and humic acid to obtain intermediate p...

Embodiment 2

[0021] A degradable slow-release fertilizer containing magnesium sulfate, the raw materials of which include by weight: 10 parts of potassium phosphate, 20 parts of ammonium nitrate, 10 parts of ammonium dihydrogen phosphate, 10 parts of potassium nitrate, 10 parts of urea, and 0.5 parts of ammonium magnesium phosphate , 0.2 parts of zinc sulfate, 0.4 parts of magnesium sulfate, 0.2 parts of ferric chloride, 0.2 parts of manganese sulfate, 10 parts of 800 mesh biochar, 10 parts of humic acid, 30 parts of coating material;

[0022] Among them, in the preparation process of the coating material, carboxymethyl chitosan and humic acid are added to dissolve in water, and then sodium persulfate, N, N-methylenebisacrylamide and 800 mesh biochar are added and mixed to obtain Solution A: Dissolve itaconic acid in water, adjust pH=7 with aqueous sodium hydroxide solution to obtain solution B; add solution B dropwise to solution A in a nitrogen atmosphere, heat up to 80°C, keep stirring f...

Embodiment 3

[0025] A degradable slow-release fertilizer containing magnesium sulfate, the raw materials of which include by weight: 20 parts of potassium phosphate, 10 parts of ammonium nitrate, 12 parts of ammonium dihydrogen phosphate, 5 parts of potassium nitrate, 15 parts of urea, and 0.4 parts of ammonium magnesium phosphate , 0.4 parts of zinc sulfate, 0.2 parts of magnesium sulfate, 0.3 parts of ferric chloride, 0.1 part of manganese sulfate, 15 parts of 600 mesh biochar, 5 parts of humic acid, 40 parts of coating material;

[0026] Among them, in the preparation process of the coating material, carboxymethyl chitosan and humic acid are added to dissolve in water, and then sodium persulfate, N, N-methylenebisacrylamide and 600 mesh biochar are added and mixed to obtain Solution A: Dissolve itaconic acid in water, adjust pH=7.5 with aqueous sodium hydroxide solution to obtain solution B; add solution B dropwise to solution A in a nitrogen atmosphere, heat up to 70°C, keep stirring fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com