Method for preparing gypsum whiskers, magnesium chloride, ammonium magnesium phosphate and ammonium chloride from phosphate tailings

A technology of gypsum whisker and magnesium ammonium phosphate is applied in the field of magnesium ammonium phosphate and magnesium chloride, the resource utilization of phosphorus tailings, magnesium chloride, and the preparation of gypsum whiskers, which can solve the problem that the poor quality of phosphogypsum cannot be utilized and the utilization of phosphorus tailings is difficult. and other problems, to achieve the effect of high added value, good product quality and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

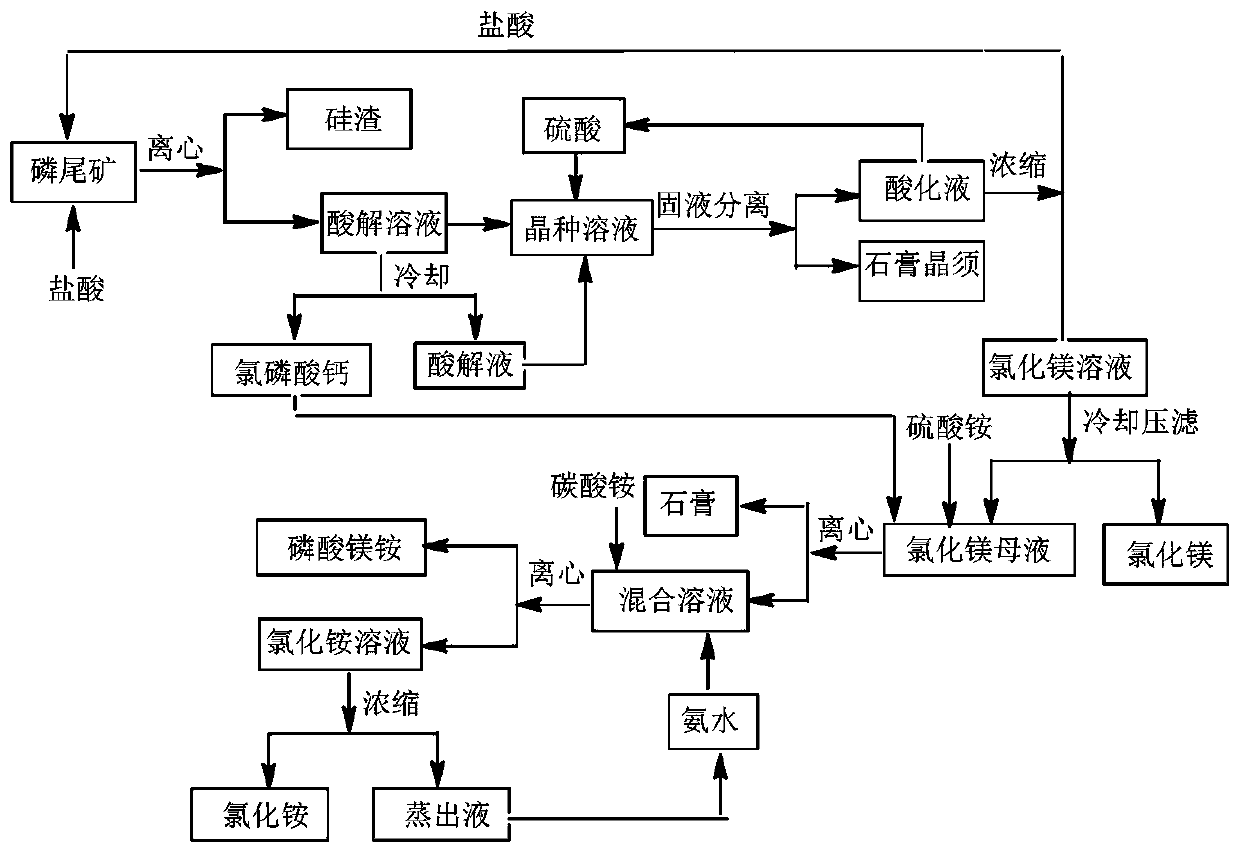

Method used

Image

Examples

Embodiment 1

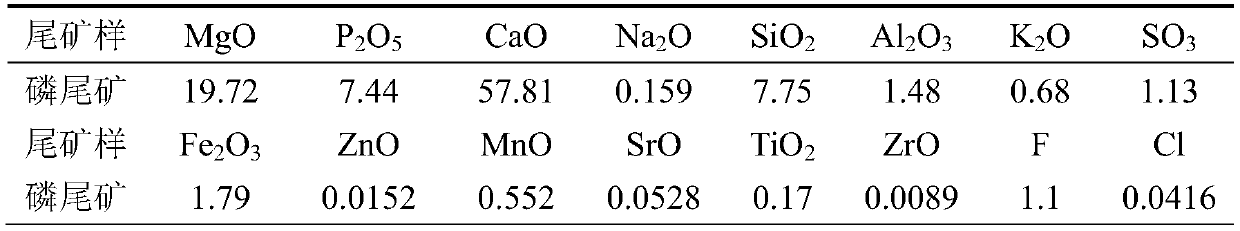

[0023] XRF elemental analysis results of flotation phosphorous tailings of a company in Hubei

[0024]

[0025] Turn on the agitator, add 100g of tailings in batches to 255mL of acidizing solution (2.50mol / L HCl) at a rotating speed of 250r / min, raise the temperature to 60°C, and add 245mL of industrial hydrochloric acid (9.65 mol / LHCl), after the dropwise addition, react at this temperature for 30 minutes, and filter while hot to obtain 7.40g of silicon slag and acidolysis solution, wash with 50mL gypsum washing water for 3 times, and the first washing liquid is incorporated into the acidolysis solution 500 mL of acid solution was obtained. The second wash was used for the first wash of the next experiment, and the third wash was used for the second wash of the next experiment. The acidolysis solution was cooled, and 1.7g of calcium chlorophosphate was precipitated, and the acidolysis solution was used to produce gypsum whiskers.

[0026] Carefully add 25.5mL of concentr...

Embodiment 2

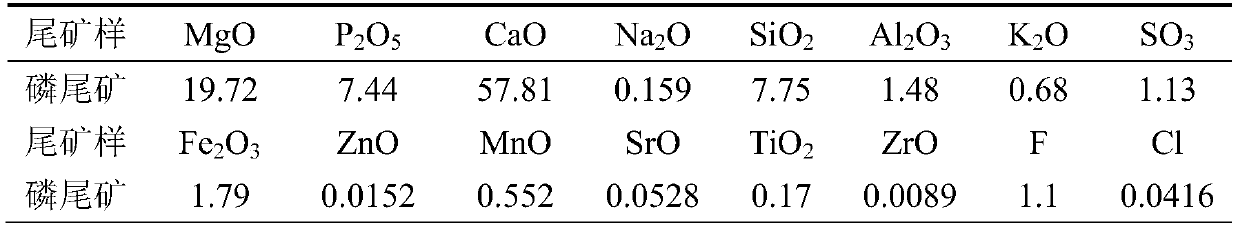

[0032] XRF elemental analysis results of flotation phosphorous tailings of a company in Hubei

[0033]

[0034]Turn on the agitator, add 200g of tailings in batches to 510mL of acidizing solution (2.50mol / L HCl) at a speed of 300r / min, raise the temperature to 60°C, and add 490mL of industrial hydrochloric acid (9.65 mol / L HCl), after the dropwise addition, react at this temperature for 30 minutes, and filter while hot to obtain 15.0 g of silicon slag and acid hydrolysis solution, wash 3 times with 100 mL of gypsum washing water, and add the acid solution to the first washing The solution was acid solution 1000mL. The second wash was used for the first wash of the next experiment, and the third wash was used for the second wash of the next experiment. The acid hydrolysis solution was cooled, and 3.6g of calcium chlorophosphate was precipitated, and the acid hydrolysis solution was used to produce gypsum whiskers.

[0035] Carefully add 51mL concentrated sulfuric acid (98%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com