Ammonium magnesium phosphate particle not stratified when mixed and disintegrating in water and preparation method of ammonium magnesium phosphate particle

A technology of magnesium ammonium phosphate and magnesium ammonium phosphate powder, which is used in ammonium orthophosphate fertilizer, phosphate fertilizer granulation/granulation, ammonium nitrate fertilizer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of the mixed magnesium ammonium phosphate particles that are not layered and meet water disintegration of the present embodiment may further comprise the steps:

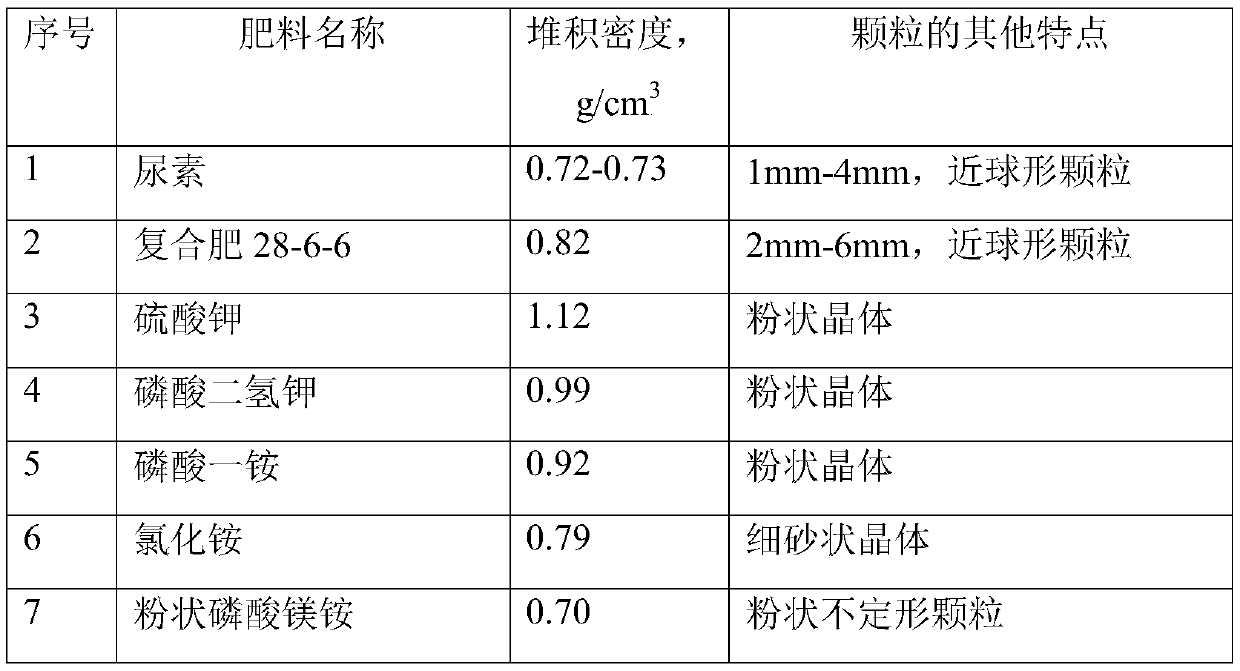

[0053] (1) The magnesium ammonium phosphate powder is dried and passed through a 32-mesh sieve, containing 1.5% of free water; in the magnesium ammonium phosphate powder, a disintegrating agent, a dispersant, a binding agent, and a desiccant auxiliary are added (the auxiliary agent is Cross 32 mesh sieves), stir and mix evenly to obtain the mixture, the specific formula of fertilizer: magnesium ammonium phosphate 95%, polyvinyl alcohol 17-88 3%, potassium sulfate 1%, bentonite 1%;

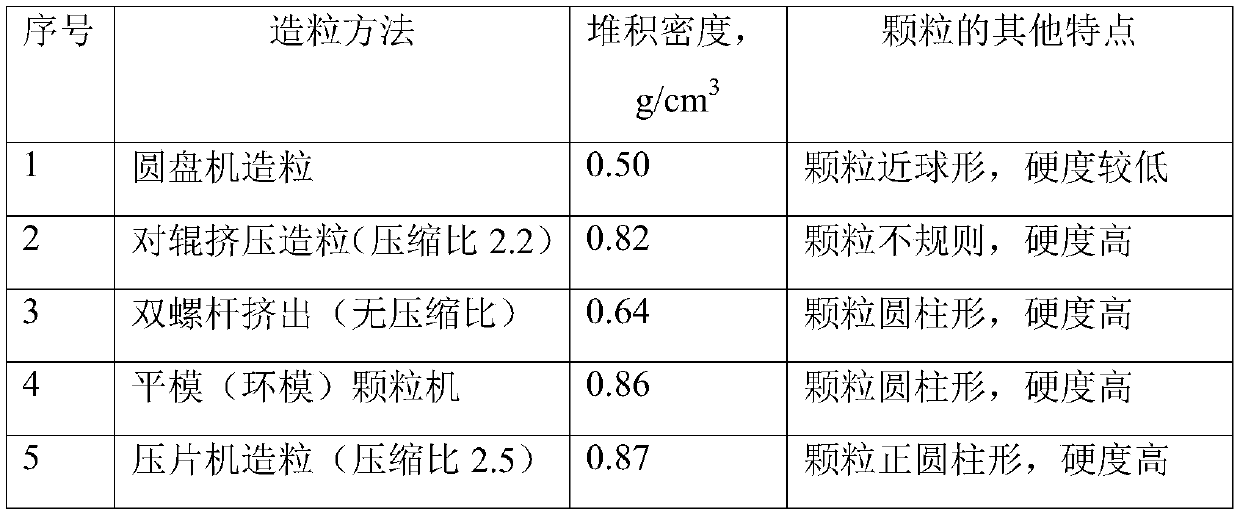

[0054] (2) Primary granulation: start the double-roll extrusion granulator (rated compression ratio 2.5), put 10kg of the mixture prepared in step (1) into the hopper of the double-roll extrusion granulator, and squeeze it into slice, crush, and sieve to obtain irregular particles of 1.5mm-3.5mm (bulk density...

Embodiment 2

[0059] The preparation method of this example is basically the same as that of Example 1, except that the feeding ratio of the secondary granulation is adjusted to 1:1, that is, 10kg of irregular particles and 10kg of mixture.

[0060] Qualified nearly spherical magnesium ammonium phosphate particles have a bulk density of 0.63g / cm 3 , Disintegrate completely within 10 minutes in water.

[0061] It can be seen that the present example increases the content of the mixture during the secondary granulation, resulting in too little bulk density of the magnesium ammonium phosphate particles, so the ratio of the mixture should be reduced during the secondary granulation, thereby increasing the bulk density.

Embodiment 3

[0063] The preparation method of the present embodiment is basically the same as that of Example 1, except that the fertilizer formula is adjusted in step (1): 95% magnesium ammonium phosphate (containing free water 3%), polyvinyl alcohol 17-88 1%, urea 2%, Bentonite 2%.

[0064] One-time granulation to obtain 1.5mm-3.5mm irregular particles with a bulk density of 0.84g / cm 3 , the qualified particle granulation rate of one operation cycle of secondary granulation is 83.5%.

[0065] Qualified nearly spherical magnesium ammonium phosphate particles have a packing density of 0.73g / cm 3 , put into water and disintegrate within 60 minutes, because the content of the disintegrating agent is reduced in this embodiment, which affects the disintegration effect of the granules, so the disintegration speed is obviously prolonged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com