Method for producing phosphate concentrate from calcareous collophanite and by-producing gypsum whiskers and magnesium ammonium phosphate

A technology for by-product gypsum and magnesium ammonium phosphate, which is applied in the field of waste resource utilization, can solve the problems of low product added value and low utilization rate of collophosphate rock, so as to increase added value, improve phosphorus taste, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

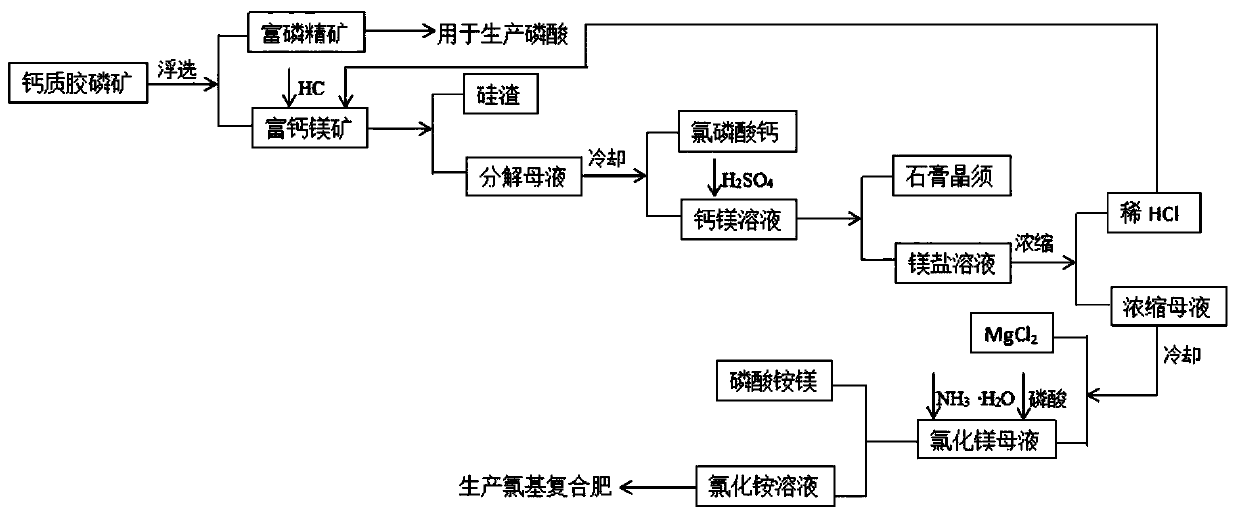

[0035] combine figure 1 As shown, the method for producing phosphate concentrate and by-product gypsum whiskers and magnesium ammonium phosphate from calcareous collophosphine of the present embodiment specifically includes the following steps:

[0036] 1) Take 500g of calcareous collophosphine and place it in the flotation machine, add 800ml of water and stir it evenly to obtain the ore pulp; add 8kg / t of sulfuric acid, 5kg / t of phosphoric acid, and 0.8kg / t of the pulp in the flotation machine in sequence After the addition of the sulfo fatty acid collector, stir for 5 minutes, then ventilate and scrape for 10 minutes to carry out reverse flotation, then drain the concentrate product and tailings product to obtain phosphorous concentrate and calcium-magnesium-rich ore. Phosphate concentrate can be used to produce phosphoric acid;

[0037] 2) Put the calcium-magnesium-rich ore obtained in step 1) into a 1000ml three-neck flask, add 195ml of hydrochloric acid with a mass fract...

Embodiment 2

[0044] combine figure 1 As shown, the method for producing phosphate concentrate and by-product gypsum whiskers and magnesium ammonium phosphate from calcareous collophosphine of the present embodiment specifically includes the following steps:

[0045] 1) Take 500g of calcareous collophosphine and place it in the flotation machine, add 850ml of water and stir it evenly to obtain the pulp; add 7kg / t of sulfuric acid, 6kg / t of phosphoric acid, and 2.2kg / t of the pulp in the flotation machine in sequence t sulfo fatty acid collector, after adding, stir for 5 minutes, then, ventilate and scrape bubbles for 12 minutes, carry out reverse flotation, then, the concentrate product and tailings product are drained to obtain phosphorus concentrate and calcium-magnesium-rich ore, phosphorus Concentrates are used to produce phosphoric acid;

[0046] 2) Put the calcium-magnesium-rich ore obtained in step 1) into a 1000ml three-necked flask, add 186ml of hydrochloric acid with a mass fract...

Embodiment 3

[0053] combine figure 1 As shown, the method for producing phosphate concentrate and by-product gypsum whiskers and magnesium ammonium phosphate from calcareous collophosphine of the present embodiment specifically includes the following steps:

[0054] 1) Take 500g of calcareous collophosphine and place it in the flotation machine, add 900ml of water and stir it evenly to obtain a pulp; add 9kg / t of sulfuric acid, 7kg / t of phosphoric acid, and 3.5kg / t of the pulp in the flotation machine in sequence After the addition of the sulfo fatty acid collector, stir for 10 minutes, then blow and bubble with air for 8 minutes, and carry out reverse flotation. Concentrates are used to produce phosphoric acid;

[0055] 2) Put the calcium-magnesium-rich ore obtained in step 1) into a 1000ml three-necked flask, add 202ml of hydrochloric acid with a mass fraction of 30.0% (10.18mol / L), and perform acidolysis reaction at 60°C for 20min, then heat-preserve and filter at 60°C to obtain decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com