Ammonium magnesium phosphate-coated fertilizer and preparation method thereof

A magnesium ammonium phosphate coating and magnesium ammonium phosphate technology, which is applied to ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, ammonium salt fertilizers, etc., can solve the problems of complex production process and short fertilizer release cycle, and achieve extended release cycle, reduce brittleness, and improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

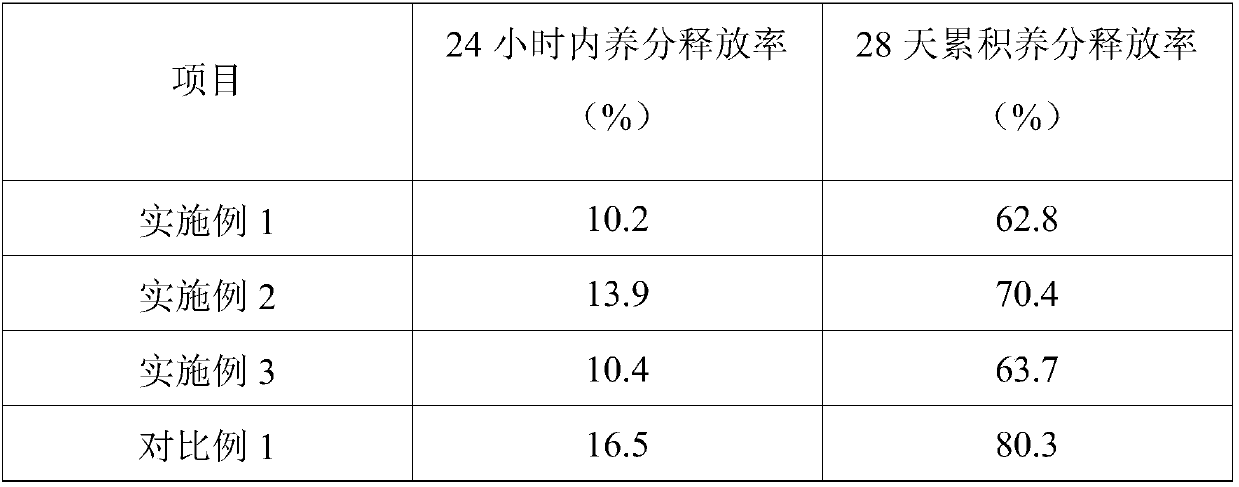

Examples

Embodiment 1

[0028] 100kg of fertilizer with a particle size of 3-4mm is added to the blast fluidized bed, preheated at 80°C, and 5kg of soybean oil preheated at 80°C is sprayed on the surface of the fertilizer. Spray 18kg of ammonium magnesium phosphate powder with a particle size of 200-270 mesh on the surface of the fertilizer sprayed with binder, dry at 80°C for 60 minutes, and finally spray 4kg of paraffin wax melted at 80°C on the fertilizer wrapped with ammonium magnesium phosphate, Prepare magnesium ammonium phosphate coated fertilizer.

[0029] Among them, the fertilizer granules include: ammonium phosphate 16wt%, ammonium sulfate 40wt%, potassium dihydrogen phosphate 34wt%, chelated copper 0.4wt%, chelated iron 0.4wt%, chelated magnesium 0.8wt%, chelated 0.4wt% of zinc, 0.5wt% of chelated calcium, 0.5wt% of borax and 7wt% of palygorskite powder. The particle size of the palygorskite powder is 200-300 mesh, and water is added to granulate by drum granulation.

Embodiment 2

[0031] 100kg of fertilizer with a particle size of 3-4mm is added to the blast fluidized bed, preheated at 65°C, and 3kg of cottonseed oil preheated at 65°C is sprayed on the surface of the fertilizer. Spray 15kg of ammonium magnesium phosphate powder with a particle size of 200-270 mesh on the surface of the fertilizer coated with binder, dry at 65°C for 30 minutes, and finally spray 2kg of paraffin wax melted at 65°C on the fertilizer wrapped with ammonium magnesium phosphate. Prepare magnesium ammonium phosphate coated fertilizer.

[0032] Among them, the fertilizer granules include: ammonium phosphate 15wt%, ammonium sulfate 35wt%, potassium dihydrogen phosphate 25wt%, chelated copper 0.2wt%, chelated iron 0.2wt%, chelated magnesium 0.7wt%, chelated 0.2wt% of zinc, 0.4wt% of chelated calcium, 0.5wt% of borax, and 3wt% of palygorskite powder. The particle size of the palygorskite powder is preferably 200-300 mesh, and water is added to granulate by drum granulation.

Embodiment 3

[0034] 100kg of fertilizer with a particle size of 3-4mm is added to the blast fluidized bed, preheated at 85°C, and 5kg of palm oil preheated at 85°C is sprayed on the surface of the fertilizer. Spray 20kg of ammonium magnesium phosphate powder with a particle size of 200-270 mesh on the surface of the fertilizer sprayed with binder, dry at 85°C for 60 minutes, and finally spray 4kg of paraffin wax melted at 85°C on the fertilizer wrapped with ammonium magnesium phosphate, Prepare magnesium ammonium phosphate coated fertilizer.

[0035] Among them, the fertilizer granules include: ammonium phosphate 20wt%, ammonium sulfate 35wt%, potassium dihydrogen phosphate 30wt%, chelated copper 0.5wt%, chelated iron 0.5wt%, chelated magnesium 0.9wt%, chelated 0.4wt% of zinc, 0.5wt% of chelated calcium, 0.7wt% of borax, and 10wt% of palygorskite powder. The particle size of the palygorskite powder is preferably 200-350 mesh, and water is added to granulate by drum granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com