Pretreatment method for wastewater of ammonia nitrogen in high density

A pretreatment technology for ammonia nitrogen wastewater, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that ammonia nitrogen cannot be recycled and reused, and achieve fast reaction speed and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

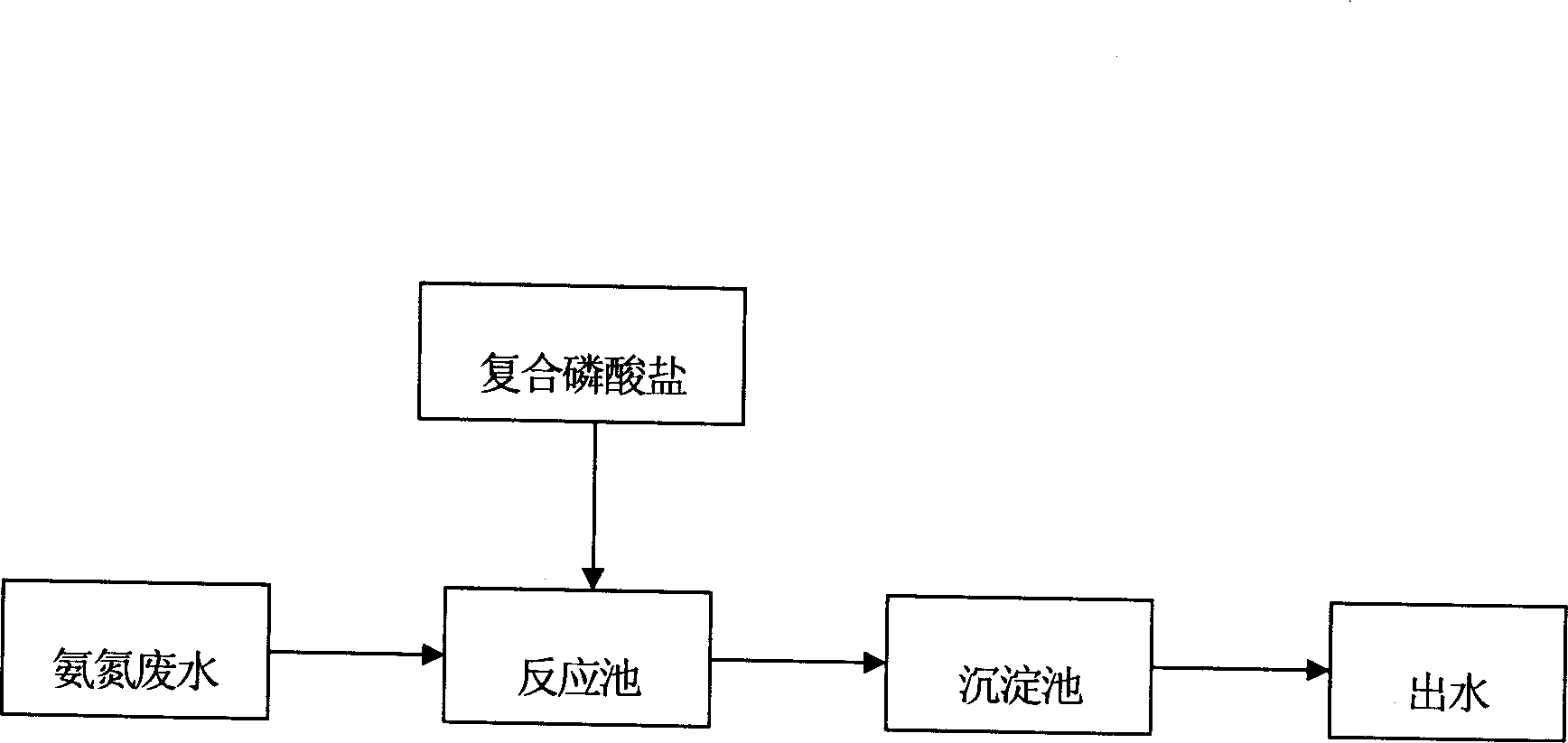

[0010] Embodiment 1: The treatment process of this embodiment is completed in a contact reactor, and the specific process flow is: ammonia nitrogen wastewater enters the reaction tank, and by adding compound phosphate in the reaction tank, the compound phosphate is formed by phosphoric acid salt, dihydrogen phosphate, hydrogen phosphate, a mixture of two or more of phosphoric acid and magnesium salt, and the molar ratio of each component in the reaction system is controlled to be magnesium salt: phosphate, dihydrogen phosphate, A mixture of two or more of hydrogen phosphate and phosphoric acid: ammonia nitrogen = 0.1 to 10: 0.1 to 10: 1.0, wherein the reaction time is 10 to 60 minutes, the pH value is 8.0 to 9.5, and then the gravity settles for 10 to 20 minutes. The supernatant is discharged from the system to complete the sewage purification. The process flow is attached figure 1 shown.

[0011] In this embodiment, the magnesium salt is magnesium chloride, magnesium oxide ...

specific Embodiment approach 2

[0020] Specific embodiment two: in the waste water that influent ammonia nitrogen concentration is 200mg / L, initial pH is 7.46, add composite phosphate, make magnesium: composite phosphate (HPO 4 2- and PO 4 3- The molar ratio is 1:3): nitrogen=1.4:0.9:1.0 (molar ratio), the system does not adjust the pH separately, the concentration of ammonia nitrogen in the effluent drops below 39.14mg / L, the removal rate is above 80.42%, and the pH of the system after the reaction is 9.23.

[0021] Specific embodiment three: adding composite phosphate to make magnesium: composite phosphate (HPO 4 2- and PO 4 3- The molar ratio is 2:1): nitrogen = 1.4:0.9:1.0 (molar ratio), the pH of the system is not adjusted separately, the concentration of ammonia nitrogen in the effluent drops below 20.93mg / L, the removal rate is 89.54%, and the pH of the system after the reaction is 9.42 .

[0022] Specific embodiment four: in the waste water that influent ammonia nitrogen concentration is 200m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com