Method for recycling waste lithium iron phosphate battery

A lithium iron phosphate battery, waste technology, applied in the direction of waste collector recycling, process efficiency improvement, carbon nanotubes, etc., can solve the problems of inability to recycle battery materials, limited practical application, environmental pollution, etc., and achieve good industrial application. Prospects, economic benefits, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

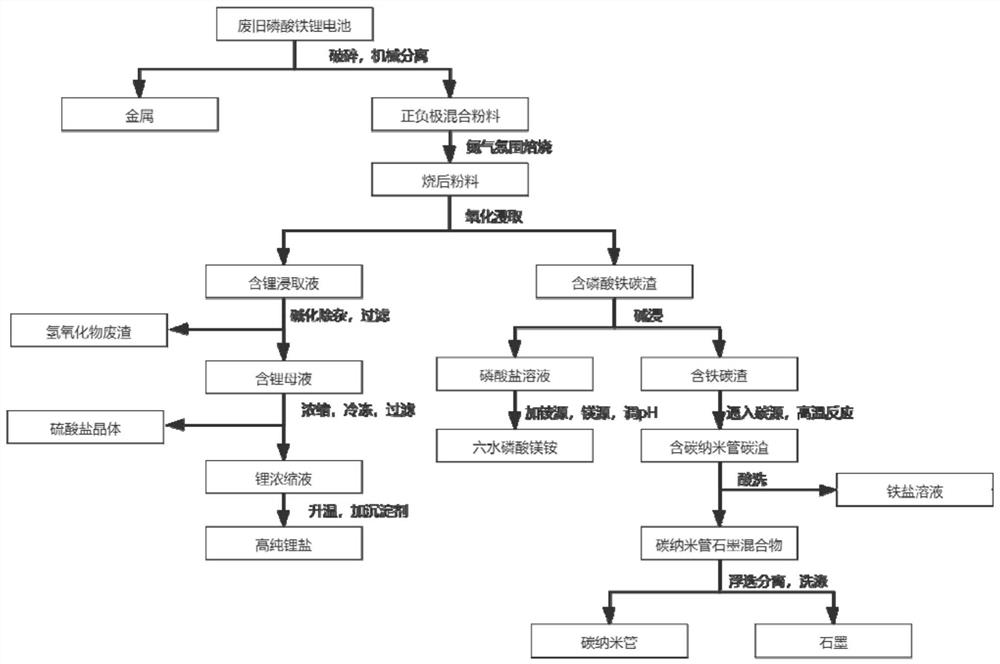

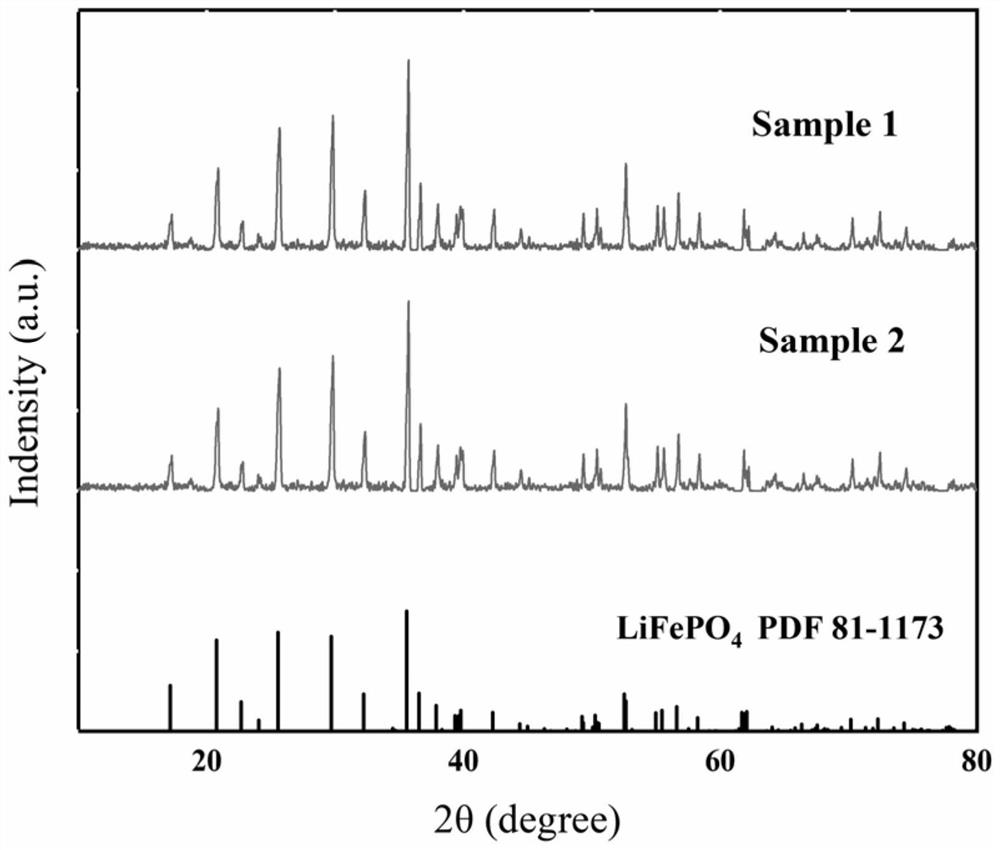

[0038] (1) if figure 1 In order to recycle the flow chart of the waste lithium iron phosphate battery method, the waste lithium iron phosphate battery to be recycled is disassembled and peeled off to obtain the mixed powder of positive and negative electrodes, which is placed in a porcelain boat without other impurities, and the porcelain boat is placed in nitrogen gas atmosphere, calcined in a kiln at a temperature of 500°C for 2h. After the treatment, the hydrophobic substances on the powder surface are removed, such as figure 2 It is the XRD pattern of lithium iron phosphate after heat treatment.

[0039] (2) Add the powder obtained in step (1) into a 0.2mol / L sodium persulfate solution with a solid-to-liquid ratio of 100g / L, stir at 25°C for 1 hour to fully dissolve the lithium in the powder in the solution, and filter.

[0040] (3) Get the filtrate after step (2) treatment, slowly add 0.1mol / L sodium hydroxide solution, adjust the pH value of filtrate to 8-9, make the ...

Embodiment 2

[0048] (1) Disassemble and peel off the waste lithium iron phosphate battery to be recycled to obtain the mixed powder of positive and negative electrodes, put it in a porcelain boat without other impurities, and place the porcelain boat in a kiln with a nitrogen atmosphere and a temperature of 500°C Calcined for 2.5h. After the treatment, the hydrophobic substances on the powder surface are removed, such as figure 2 It is the XRD pattern of lithium iron phosphate after heat treatment.

[0049] The firing temperature is 200-1000°C, preferably 300-800°C, more preferably 400--600°C. The firing time is 1-5 hours, preferably 1.5-4 hours, more preferably 2-3 hours.

[0050] (2) Take the powder obtained in step (1) and add it to a 0.4mol / L sodium persulfate solution with a solid-to-liquid ratio of 150g / L, stir at 35°C for 1 hour to fully dissolve the lithium in the powder in the solution, and filter.

[0051] (3) Get the filtrate after step (2) treatment, slowly add 0.15mol / L so...

Embodiment 3

[0059] (1) Disassemble and peel off the waste lithium iron phosphate battery to be recycled to obtain the mixed powder of positive and negative electrodes, put it in a porcelain boat without other impurities, and place the porcelain boat in a kiln with a nitrogen atmosphere and a temperature of 700°C Calcination 2h. After the treatment, the hydrophobic substances on the powder surface are removed.

[0060] (2) Add the powder obtained in step (1) into a 0.3mol / L sodium persulfate solution with a solid-to-liquid ratio of 200g / L, stir at 40°C for 1.5h to fully dissolve the lithium in the powder in the solution, and filter.

[0061] (3) Get the filtrate after step (2) treatment, slowly add 0.2mol / L sodium hydroxide solution, adjust the pH value of filtrate to 8-9, make the iron, aluminum, copper ion in the filtrate with the concentration of hydroxide The formal precipitate was removed and filtered.

[0062] (4) Concentrate the filtrate treated in step (3) to half of its original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com