Black membrane biogas digester

A biogas collection pipe and anti-seepage membrane technology, which is applied to gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problem of high cost of biogas digesters, and achieve the effects of low construction cost, convenient and simple construction, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with the accompanying drawings the specific embodiment of the present invention is further described as follows:

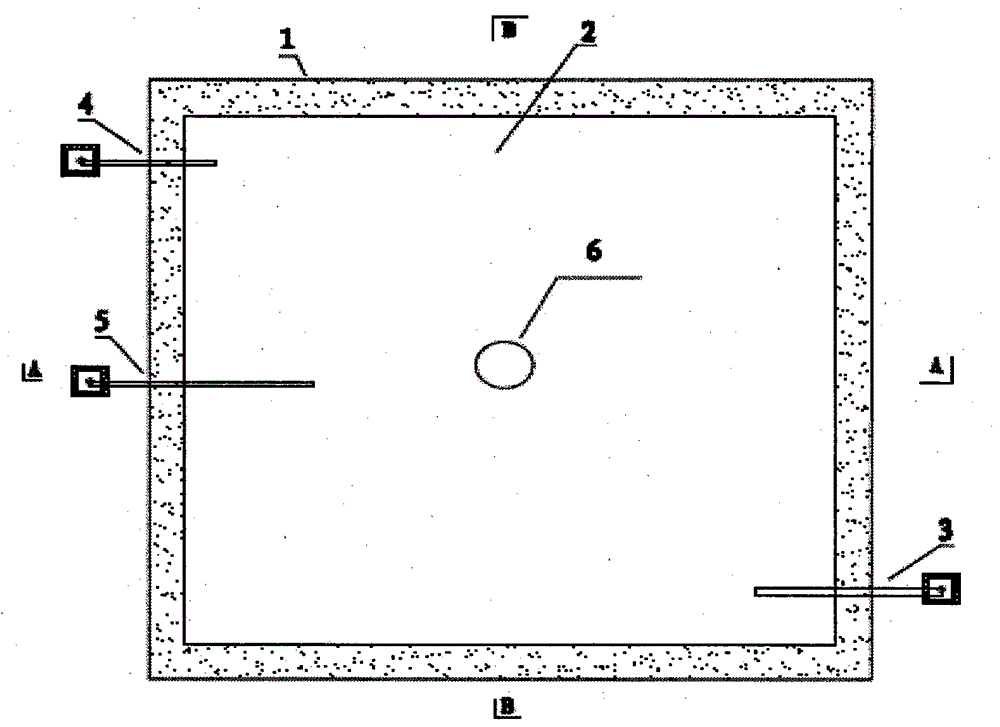

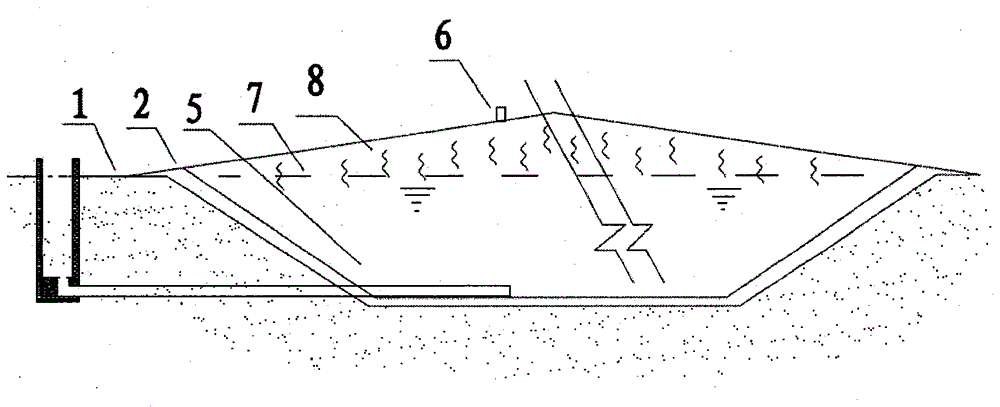

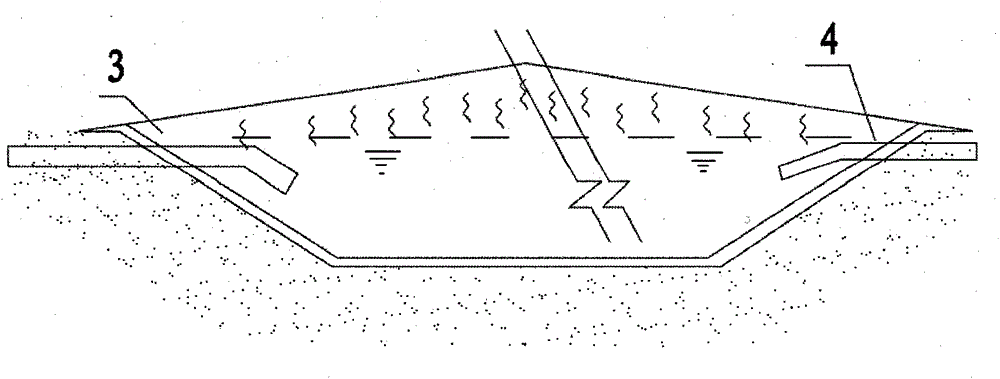

[0017] From figure 1 and image 3 It can be seen that the present invention is a black-membrane biogas digester, which mainly includes: 1 soil pit 2 HDPE anti-seepage membrane 3 water inlet 4 water outlet 5 slag pumping pipe 6 biogas collection pipe 7 fermentation liquid level 8 biogas, 3 water inlets in the figure 4 water outlet 5 slag pumping pipe 6 biogas collecting pipe 7 fermentation liquid level 8 biogas, these are the same features shared by biogas digesters in my country, so they will not be described in detail. The earth pit 1 is an ordinary earth pit dug by an excavator according to requirements, and is built below the ground level or semi-underground, and the depth is determined according to the geological conditions of each place. Lay a layer of HDPE anti-seepage film 2 in the excavated earth pit, cover the upper mouth of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com