Method for producing methane by carrying out co-digestion on pig manure and tea-oil tree shell

A technology of camellia oleifera shell and biogas production, which is applied in the petroleum industry, gas fuel, waste fuel, etc. It can solve the problems of secondary pollution, low added value of products, and low input and output, so as to increase gas production and improve raw material utilization rate and energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

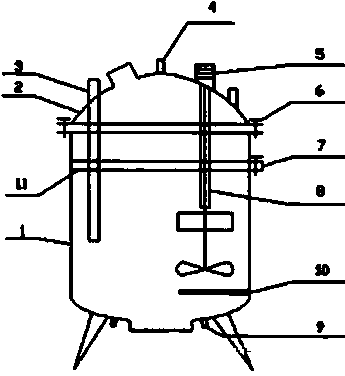

[0026] assembled as figure 1 The controllable thermostatic anaerobic stainless steel fermenter shown has a total volume of 30L and an effective volume of 24L. The device has a built-in heating rod to heat up, and the temperature is controlled by a thermocouple inserted into the tank, and the generated gas is connected to a gas flow meter through the gas outlet to measure the daily gas production. The generator speed is set at 27r / min, and it keeps rotating all the time, and the amount of gas produced is measured once a day by a gas flow meter.

[0027] The design temperature of this example is 50°C, pH=6~8, fermentation broth TS=6%, hydraulic retention time 15 days, add 720g pig manure and 4.7L inoculum (the TS of the inoculum is negligible) into the fermenter, and wait for When the fermentation gas production tends to be stable, the mixed raw materials of camellia oleifera husk and pig manure will be input semi-continuously.

[0028] Crush the camellia oleifera shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com