Biomass gasification furnace

A gasification furnace and biomass technology, applied in the field of stoves, can solve the problems of affecting gas production, inability to supply gas, and the position of the gasification layer is not fixed, so as to achieve the effect of uniform gas production and increased calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

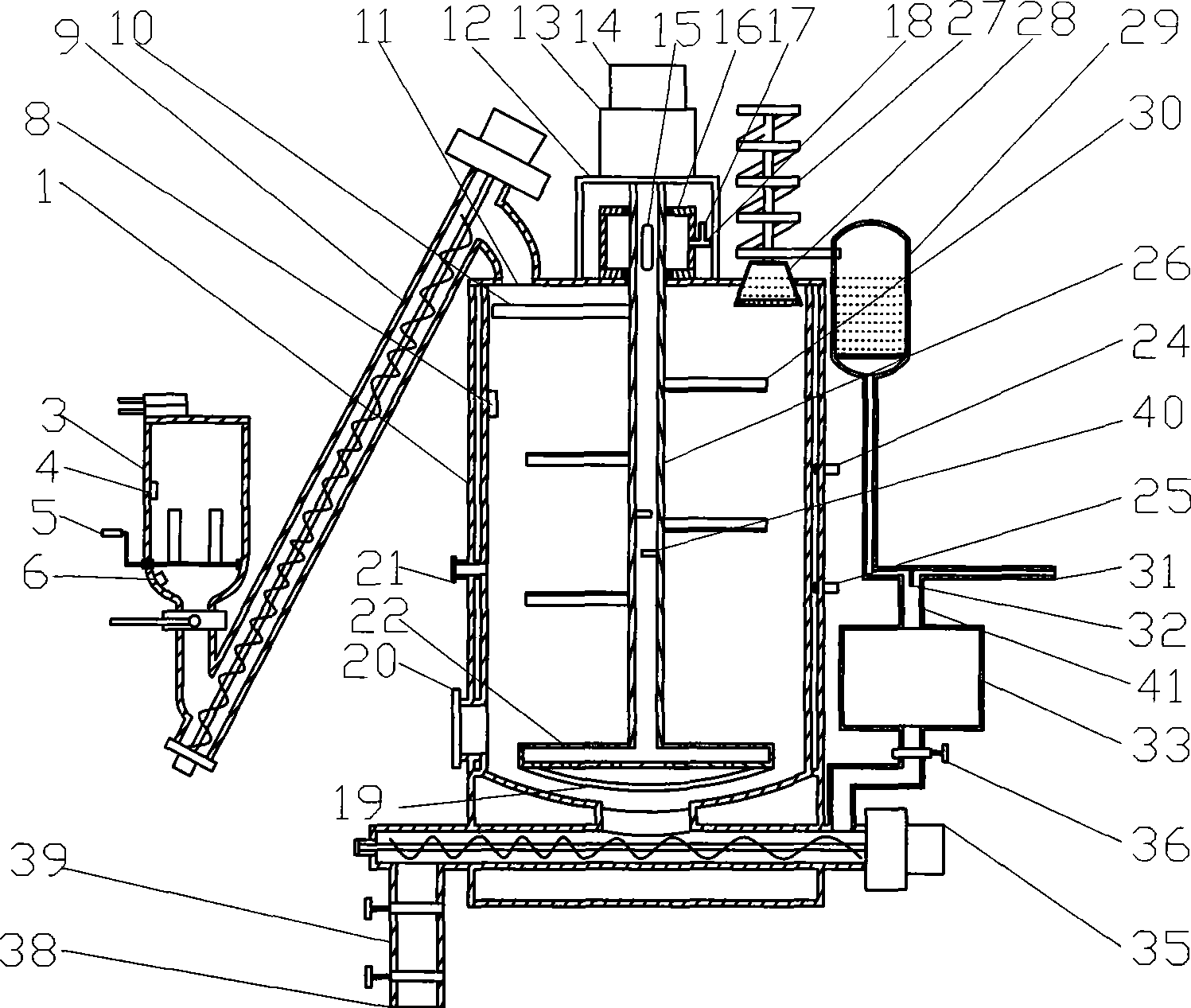

[0023] Further description will be made below in conjunction with the accompanying drawings, but not limited thereto.

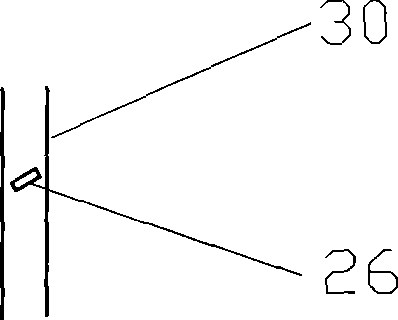

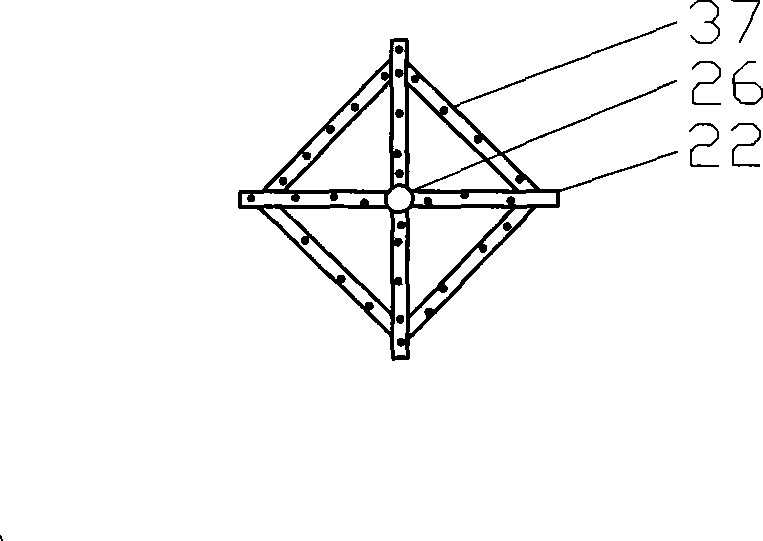

[0024] Such as figure 1 , 2 , 3, the present invention comprises a body of furnace 1, a feed inlet 11 opened on the top of the body of furnace 1 and a filter 28 embedded in its top, a fire viewing port 21 and an ignition port 20 opened on the side wall of the body of furnace 1, and The water inlet pipe 25 and the water outlet pipe 24 of the body of furnace 1 interlayer water supply and drainage, the radiator 27 connected with the filter 28, the purifier 29 connected with the radiator 27, the gas outlet pipe 31 connected with the purifier 29, and the furnace The ash outlet 38 connected to the bottom of the body 1, and the stirring shaft 26, the stirring tooth 30 on the stirring shaft 26 in the body of heater 1, the stirring shaft motor 14 coaxial with the stirring shaft 26 outside the body of furnace 1, Stirring shaft reducer 13, support frame 12 supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com