Method for producing biogas by aid of intensified anaerobic fermentation of circular backflow sludge in microwave and alkali combined treatment

A technology of combined treatment and recirculation, which is applied in the field of solid waste recycling, can solve the problems that the anaerobic digestion process has not received attention, limits the advantages of anaerobic digestion technology, and the sludge has a long residence time, so as to promote the recycling of sludge , shorten the residence time, the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

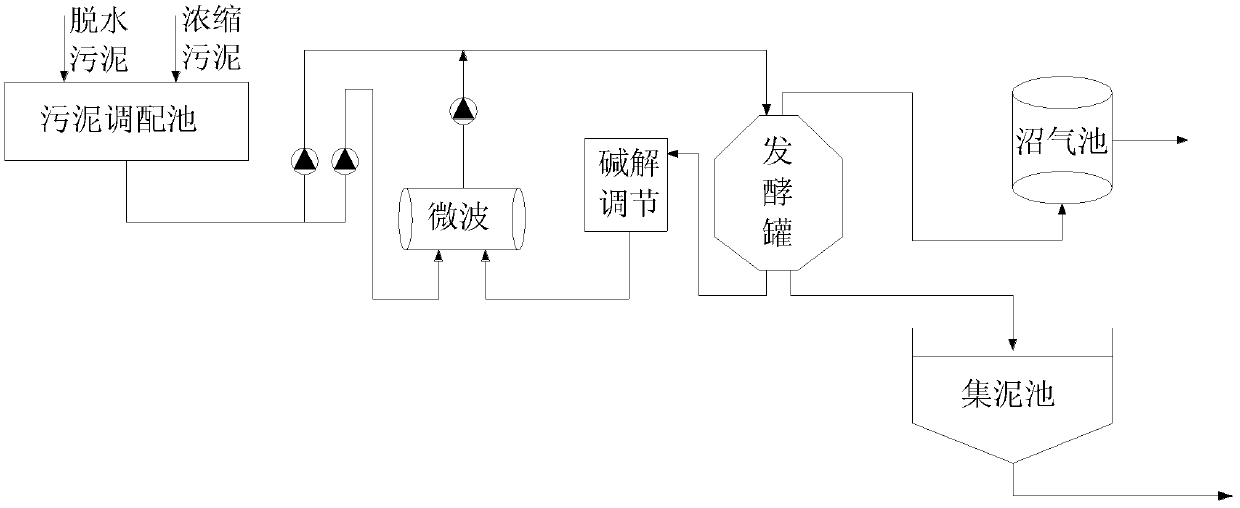

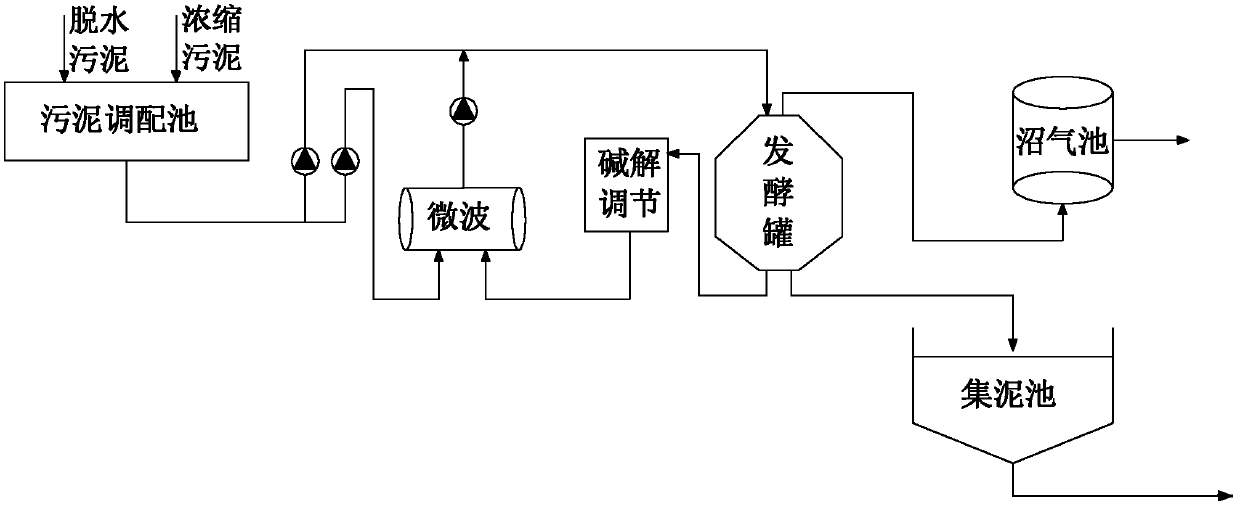

[0024] figure 1 A flow chart showing the method of the present invention for combined microwave and alkali treatment of circulating sludge to enhance anaerobic fermentation to generate biogas.

[0025] Take the concentrated sludge and dewatered sludge from a sewage treatment plant in a certain place and prepare mixed sludge with a water content of 92% and a VS / TS of 0.45 in a sludge blending tank. The daily normal feeding and discharging are as follows: Take 1L of the above mixed sludge and put it into a 20L effective volume fermenter, and discharge 1L into the sludge collection tank at the same time (the corresponding residence time is 20d). In addition, a circulation outlet is set at the lower end of the fermenter, and 1L of cooked mud (reflux ratio is 5%) is reflowed to the alkali hydrolysis regulating device by gravity every day, and NaOH is added under the stirring condition of 120rpm, and the dosage of NaOH is 0.05g / gVS, and then put it into the microwave irradiation d...

Embodiment 2

[0030] Take the concentrated sludge and dewatered sludge from a sewage treatment plant in a certain place and prepare mixed sludge with a water content of 98% and a VS / TS of 0.75 in a sludge blending tank. The daily normal feeding and discharging are as follows: Take 2L of the above mixed sludge and put it into a 60L effective volume fermenter, and discharge 2L into the sludge collection tank at the same time (the corresponding residence time is 30d). In addition, a circulation outlet is set at the lower end of the fermenter, and 4L cooked mud (reflux ratio is 6.7%) is reflowed to the alkaline hydrolysis regulating device by gravity every day, and CaO is added under the stirring condition of 120rpm, and the dosage of CaO is 0.10g / gVS, and then put it into the microwave irradiation device, the microwave frequency is 2450MHz, after 10 minutes of microwave irradiation under the condition of 600W, adjust the pH to 7.5±0.5 by adding hydrochloric acid, and pump it into the fermenter...

Embodiment 3

[0035] Take the concentrated sludge and dewatered sludge from a sewage treatment plant in a certain place and prepare mixed sludge with a moisture content of 88% and a VS / TS of 0.33 in a sludge blending tank. The daily normal input and output are as follows: take 800mL of the above mixed sludge and put it into a 20L effective volume fermenter, and at the same time discharge 1L into the sludge collection tank (the corresponding residence time is 25d). In addition, a circulation outlet is set at the lower end of the fermenter, and 2L of cooked mud (reflux ratio is 10%) is reflowed to the alkaline hydrolysis regulating device by gravity every day, and Ca(OH) is added under the stirring condition of 120rpm 2 , Ca(OH) 2 The dosage is 0.15g / gVS, and then put into the microwave irradiation device, the microwave frequency is 2450MHz, after 5 minutes of microwave irradiation under the condition of 800W, the pH is adjusted to 7.5±0.5 by adding hydrochloric acid, and the sludge is circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com