Methods and apparatus to generate liquid ambulatory oxygen from an oxygen concentrator

a technology of liquid oxygen and concentrator, which is applied in the direction of containers discharging from non-pressured vessels, non-pressured vessels, and packaged goods. it can solve the problems of not being able to leave the home, cumbersome and unwieldy, and both gaseous oxygen and liquid oxygen options have substantial drawbacks. , to achieve the effect of small liquid film thickness and enhanced condensation rate per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

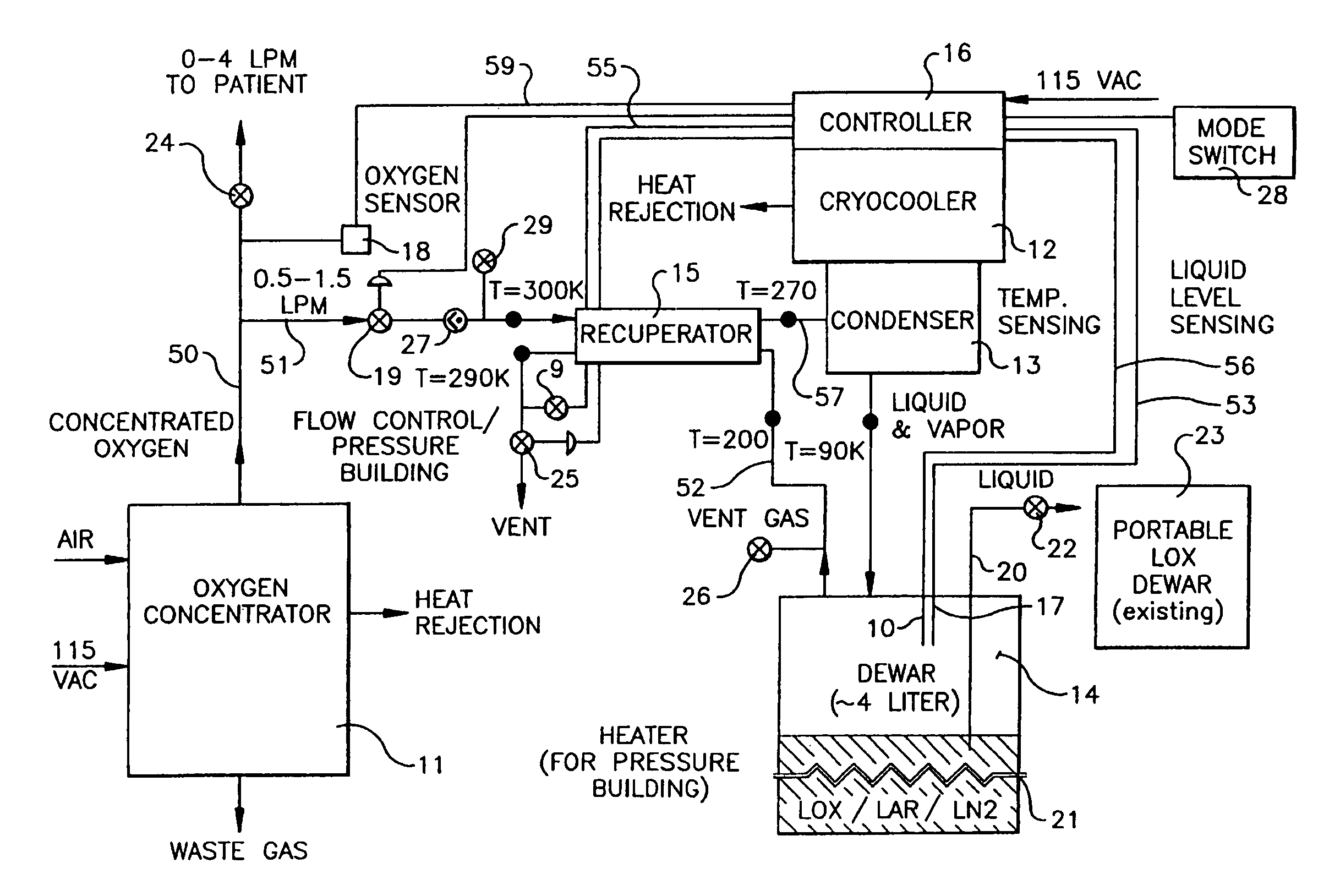

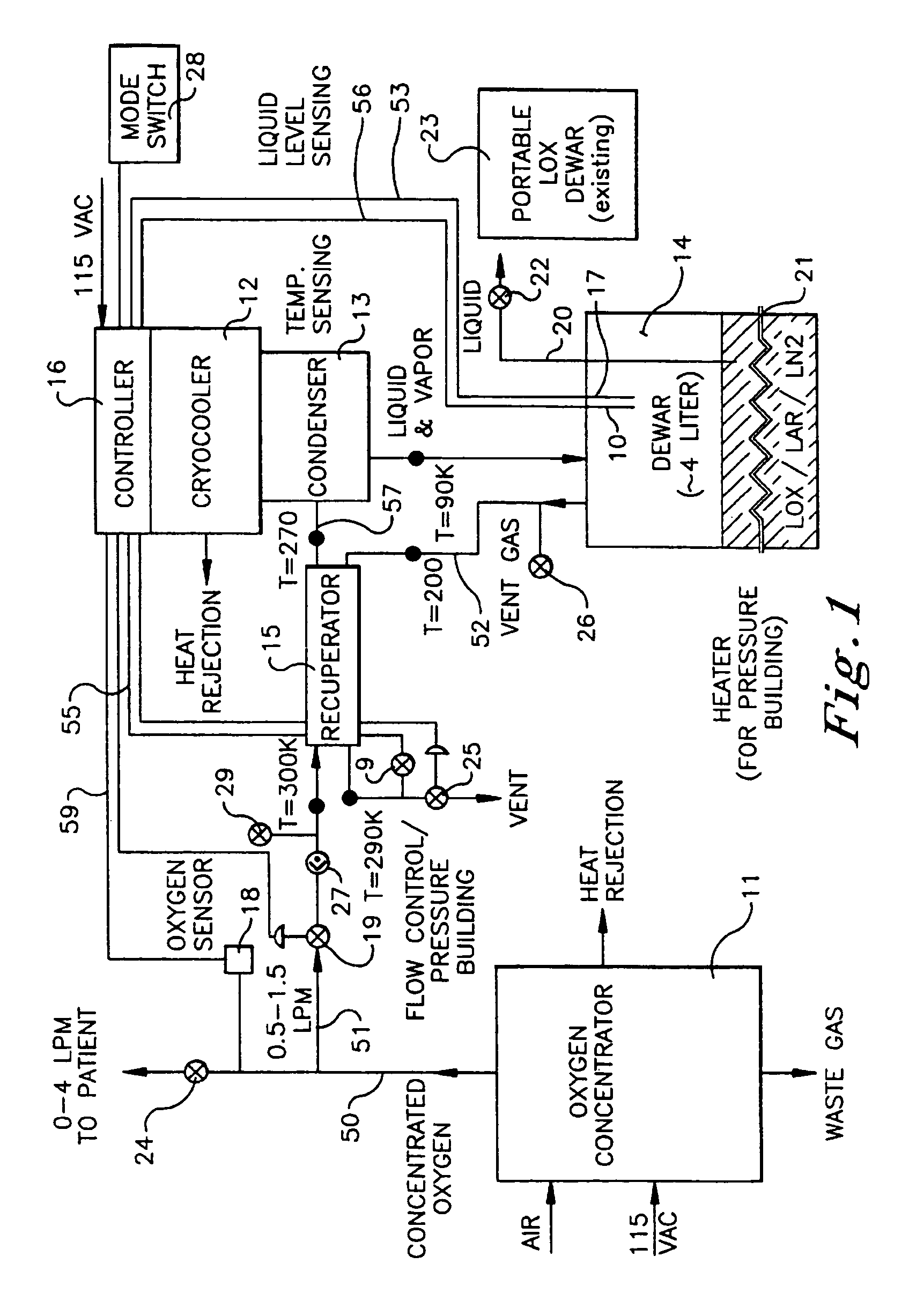

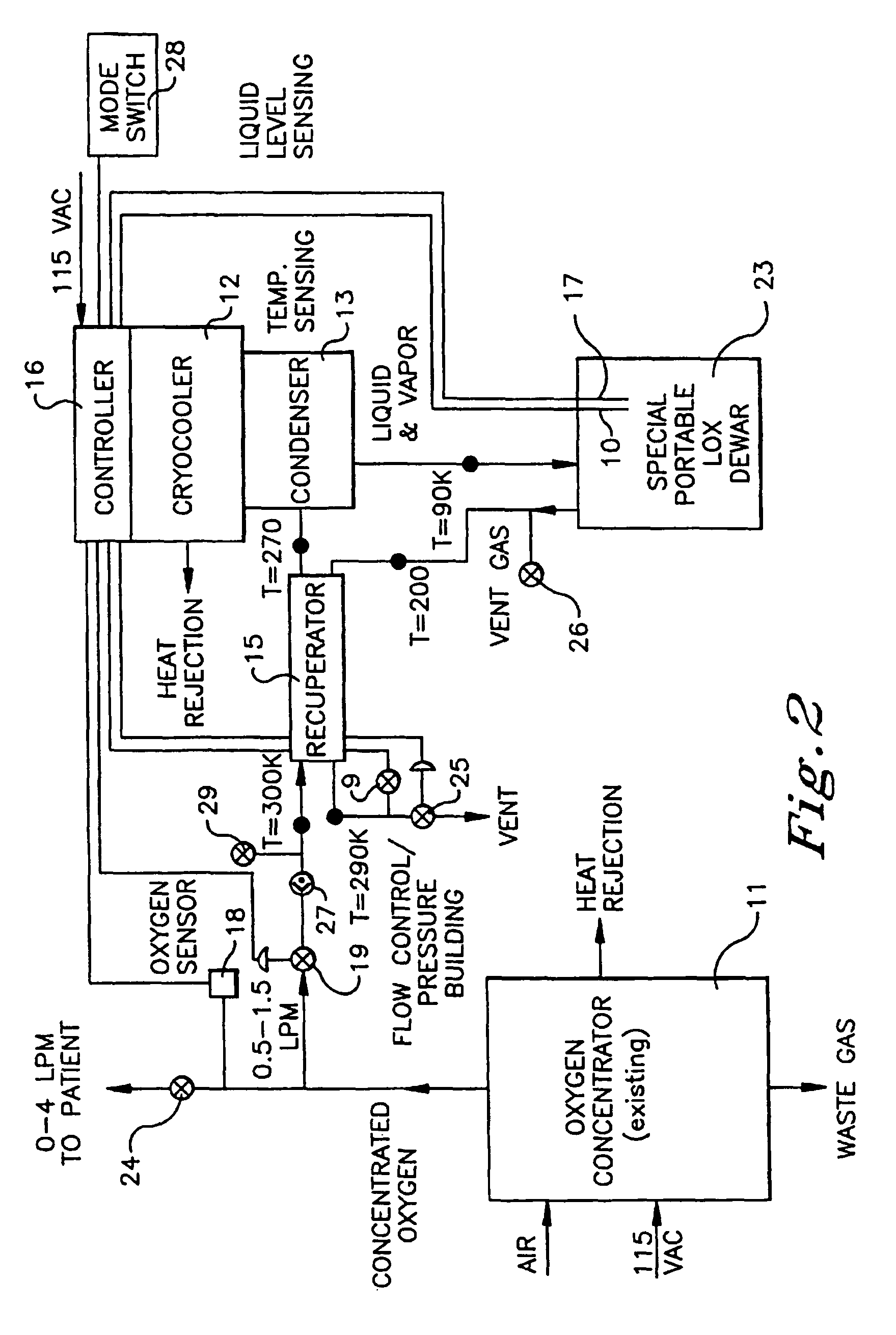

[0076]A flow chart of the preferred embodiment of the invention is set out in FIG. 1. Its main components include an oxygen concentrator 11, a cryocooler 12, a condenser 13, and a storage / collection dewar or vacuum insulated container 14. In the preferred embodiment, the oxygen concentrator 11 operates on a pressure swing adsorption cycle and essentially strips all or most of the nitrogen from air along with other minor components such as H2O, CO2, CO, NOx, etc. The result is a stream of dry gas with high oxygen concentration (˜92%) flowing in fluid outlet 50. A portion of the gas from this output in fluid outlet 50 is routed to a condenser 13 in association with a cryocooler (or cryogenic refrigerator) 12 through flow lines 51 and 57. The cryocooler provides cooling of the condenser heat exchanger 13 to liquefaction temperatures, causing the oxygen in contact therewith to go from the gaseous to the liquid phase. The condenser 13 typically must be insulated from ambient heating and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| boiling points | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com