LED chip electrode, LED chip structure and fabrication methods of LED chip electrode and LED chip structure

An LED chip and manufacturing method technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as failure of light-emitting diodes, decreased luminous efficiency, abnormal light decay, etc., to increase migration rate, save manufacturing costs, and simplify process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A light emitting diode with wrapped electrodes is prepared through the following process steps.

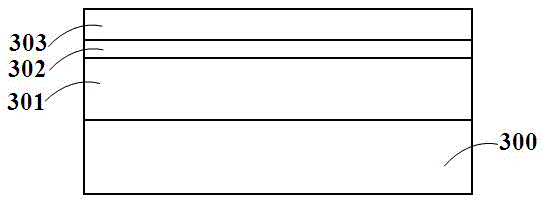

[0054] Such as image 3 As shown, a substrate is provided, and the substrate can be a substrate or a light-emitting epitaxial layer or a combination of the two. In this implementation, the preferred substrate is a sapphire substrate; on the sapphire substrate 300, metal organic compound chemical vapor deposition (English Abbreviated as MOCVD) light-emitting epitaxial layer, which sequentially includes an N-type layer 301 , a light-emitting layer 302 , and a P-type layer 303 from bottom to top.

[0055] Such as Figure 4 As shown, in the light-emitting epitaxial layer, a partially exposed N-type layer 301 is etched downward from the surface of the P-type layer 303 by using a mask and dry etching technology.

[0056] Such as Figure 5 As shown, a current spreading layer 304 is formed on the surface of the P-type layer 303 of the light-emitting epitaxial layer material, and...

Embodiment 2

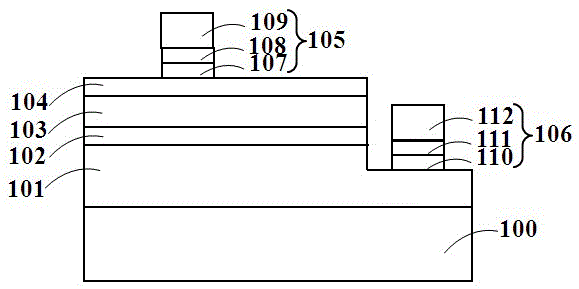

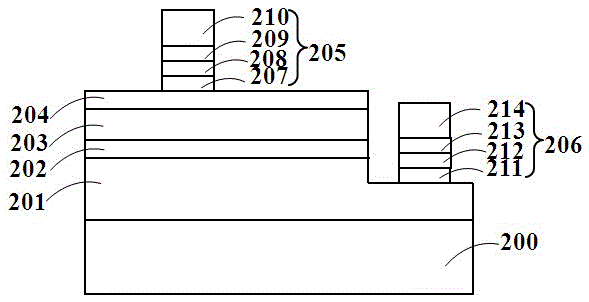

[0063] Such as Figure 10 As shown, the difference from Embodiment 1 is that the reflective structure of this embodiment is formed by sputtering, that is, the metal reflective layers 407 and 412, the first metal isolation layers 408 and 413, and the second metal isolation layer 409 are sequentially sputtered. The metal reflective structure composed of 414 and 414, the sides of each structural layer are inclined, and the cross-sectional view of the metal reflective structure is a trapezoidal shape with a narrow top and a wide bottom, so that the metal surface layer formed by the subsequent ion source plating method is better coated on the metal reflector. Structurally, the contact between the oxidant and the metal Al or Ag in the reflective structure is isolated, and good coating can also alleviate the migration and precipitation of the metal Al or Ag, thereby further improving the reliability of the light emitting diode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com