Moving arm, chemical mechanical grinding trimmer and grinding equipment

A technology of arms and shells, which is applied in the field of semiconductor manufacturing, can solve problems such as droplet drop and achieve the effect of preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

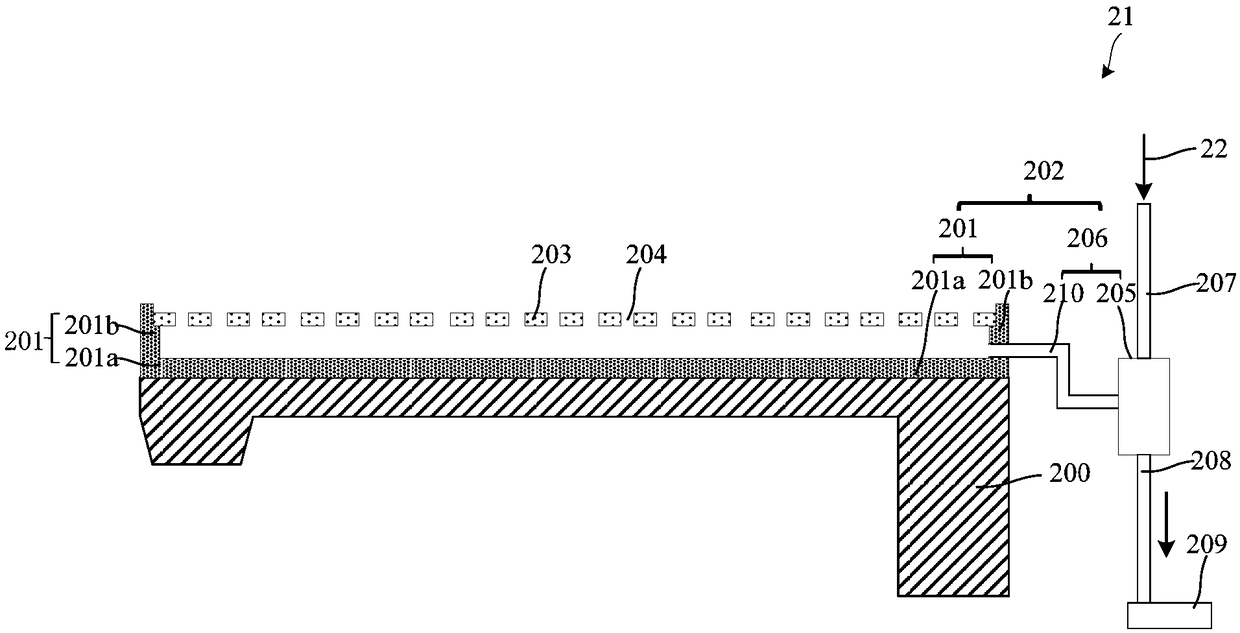

[0030] refer to figure 1 , the mobile arm 21 includes: an arm body, a shell 200 covering the arm body, and a liquid storage device 202 located on the surface of the shell 200, the liquid storage device 202 is used to store the liquid droplets accumulated on the shell, and the stored The droplets drain into downcomer 209 .

[0031] The arm body of the moving arm 21 includes a support component, transmission components, drive components, liquid pipelines and / or related circuits installed on the support component, so that the arm has functions such as moving, holding or absorbing. The movement includes horizontal movement, vertical movement, rotation, or stretching, and the holding or absorbing includes holding or absorbing the trimming disk and the liquid ejection head.

[0032] In one embodiment, the transmission component comprises a shaft transmission, a gear transmission or a belt transmission. The driving device includes a motor driving device or an air cylinder driving d...

no. 2 example

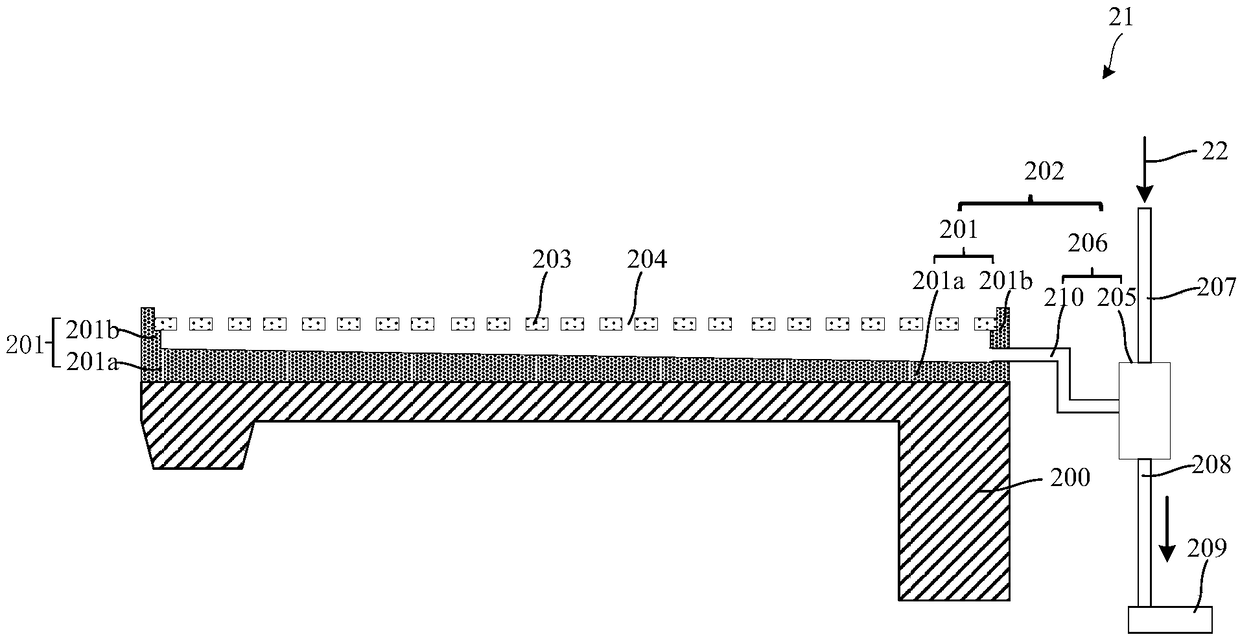

[0045] refer to figure 2 The difference between this embodiment and the previous embodiments is that the bottom plate 201a in this embodiment has an inclined surface, and the inclined surface is inclined toward the direction of the liquid discharge part 206, so that the liquid flowing from the cover plate 203 on the bottom plate 201a The liquid droplets can easily flow to the direction of the drain pipe 210 , and are conveniently discharged from the liquid discharge pipe 210 , so that the liquid droplets will not be left on the bottom plate 201 a and keep the bottom plate 201 a dry.

[0046] In one embodiment, the inclination angle of the surface of the bottom plate 201a is 30-80°.

[0047] It should be noted that, the definition or description of the same or similar structure in this embodiment as in the previous embodiment will not be repeated in this embodiment, and please refer to the definition or description of the corresponding part in the previous embodiment for detai...

no. 3 example

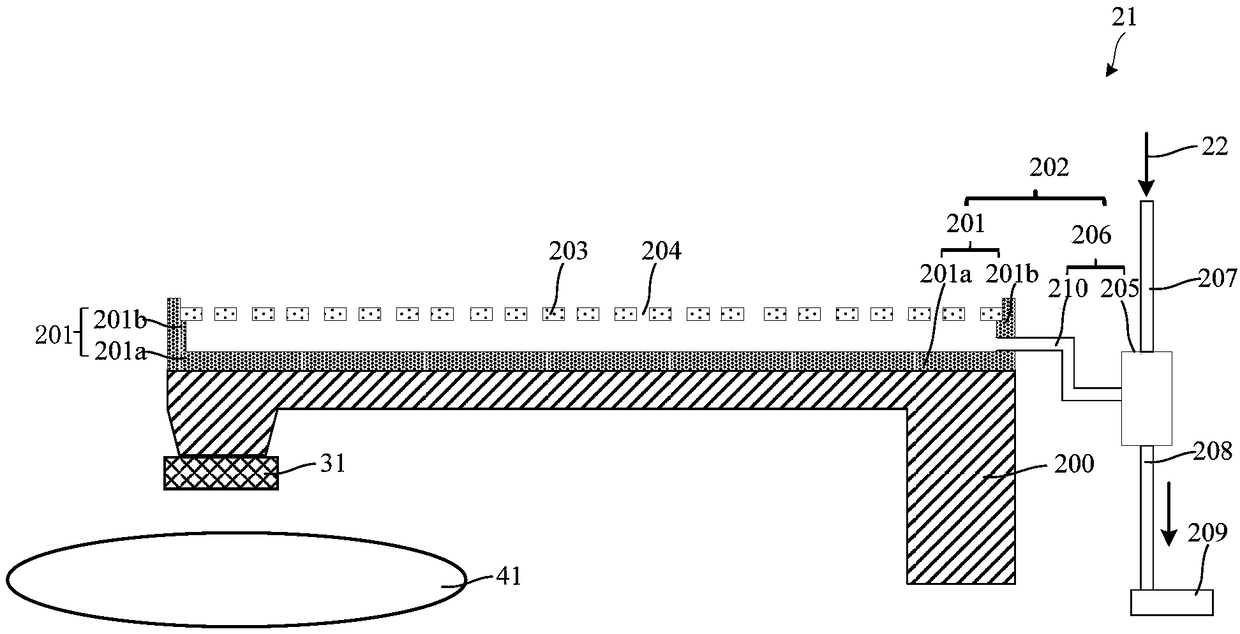

[0049] refer to image 3 , the present invention also provides a chemical mechanical abrasive dresser, including the moving arm 21 described in the foregoing embodiments; the head of the moving arm 21 is equipped with a dressing disc 31 .

[0050] In this embodiment, the moving arm 21 can perform one or more actions of vertical movement, horizontal movement and rotation. Both the vertical movement and the horizontal movement are linear movements.

[0051] The conditioning disc 31 is rotatable.

[0052] When the dresser of the embodiment of the present invention is used for dressing, the liquid droplets on the arm can be prevented from dripping onto the grinding pad to be dressed below.

[0053] It should be noted that, the definition or description of the same or similar structures in this embodiment and the foregoing embodiments will not be repeated in this embodiment. For details, please refer to the definitions or descriptions of corresponding parts in the foregoing embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com