Method for preparing hydrogen-rich fuel gas through high-humidity sludge gasification based on blast furnace slag waste heat recovery

A technology of waste heat recovery and sludge gasification, which is applied in the field of sludge resource utilization, can solve the problems of large energy consumption, difficulty in generating economic value, high water content of sludge, etc., and achieve high-efficiency quality-based utilization and high energy utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

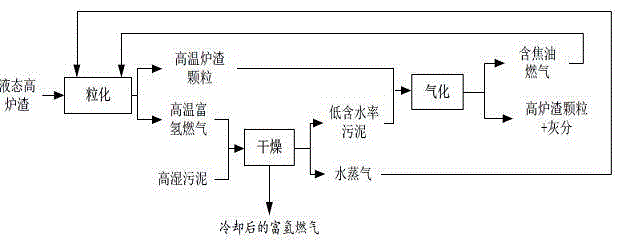

Image

Examples

Embodiment 1

[0021] The method for producing hydrogen by blending gasification of sludge and biomass described in this example is as follows:

[0022] (1) The liquid blast furnace slag is made into slag particles at a temperature of 900°C through air quenching granulation technology, and the particle size is controlled below 2mm;

[0023] (2) The high-temperature gas with a temperature between 200 and 300 °C generated during the slag granulation process is used as a heat source for drying high-humidity sludge, and conducts indirect heat exchange with the sludge, so that the moisture in the sludge is partially removed, and the moisture content is low after drying. The water content in the high-rate sludge is controlled at 20%, and water vapor is generated at the same time;

[0024] (3) Mix high-temperature slag particles and low-moisture sludge with a moisture content of 20% at a mass ratio of 1:1. After the sludge and slag particles are in contact with each other for heat exchange, they wi...

Embodiment 2

[0028] The method for producing hydrogen by blending gasification of sludge and biomass described in this example is as follows:

[0029] (1) The liquid blast furnace slag is made into slag particles at a temperature of 1000°C through air quenching granulation technology, and the particle size is controlled below 2mm;

[0030] (2) The high-temperature gas with a temperature between 200 and 300 °C generated during the slag granulation process is used as a heat source for drying high-humidity sludge, and conducts indirect heat exchange with the sludge, so that the moisture in the sludge is partially removed, and the moisture content is low after drying. The water content in the high-rate sludge is controlled at 25%, and water vapor is generated at the same time;

[0031] (3) Mix high-temperature slag particles and low-moisture sludge with a moisture content of 30% according to a mass ratio of 1.2:1. After the sludge and slag particles contact and exchange heat, they will rapidly...

Embodiment 3

[0035] The method for producing hydrogen by blending gasification of sludge and biomass described in this example is as follows:

[0036] (1) The liquid blast furnace slag is made into slag particles at a temperature of 1100°C through air quenching granulation technology, and the particle size is controlled below 2mm;

[0037] (2) The high-temperature gas with a temperature between 200 and 300 °C generated during the slag granulation process is used as a heat source for drying high-humidity sludge, and conducts indirect heat exchange with the sludge, so that the moisture in the sludge is partially removed, and the moisture content is low after drying. The water content in the high-rate sludge is controlled at 40%, and water vapor is generated at the same time;

[0038] (3) Mix high-temperature slag particles and low-moisture sludge with a moisture content of 40% at a mass ratio of 1.5:1. After the sludge and slag particles contact and exchange heat, they will rapidly heat up a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com