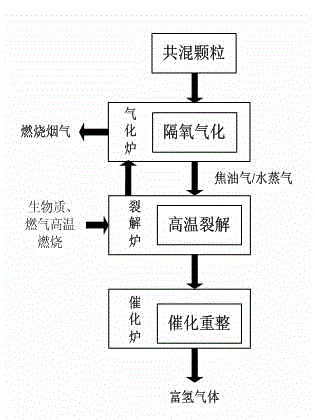

Method and device for producing hydrogen through blending and gasifying of sludge and biomass

A biomass and blending technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of food safety risks, poor catalytic cracking effect, negative effects, etc. The effect of reducing catalyst carbon deposition and efficient utilization of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

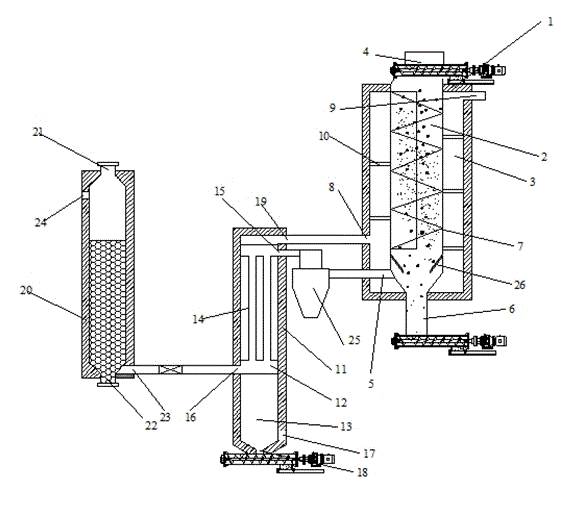

[0024] Such as figure 1 As shown, the device of the present invention using sludge and biomass blended gasification to produce hydrogen is an externally heated sludge and biomass blended gasification-tar cracking-catalytic reforming ternary composite hydrogen production The device includes a gasification furnace, a high-temperature cracking furnace and a catalytic reforming furnace, respectively performing sludge and biomass gasification, tar gas high-temperature cracking and catalytic reforming.

[0025] The gasification furnace 1 includes a gasification chamber 2 and an external heating chamber 3. The top of the gasification chamber 2 is provided with a blended particle feeder 4, and the bottom is provided with a gasification tar gas outlet 5 and a gasification ash outlet 6. The gasification chamber 2 There are spiral guide vanes 7 inside; the bottom of the outer heating chamber 3 is equipped with a high-temperature flue gas inlet 8, and the upper part is equipped with a hig...

Embodiment 2

[0038] The method for producing hydrogen by blending gasification of sludge and biomass described in this example is as follows:

[0039] (1) Dewatering the municipal sludge. After dehydration, it does not need to be dried and blended with the crushed organic waste particles to form particles for gasification; Water content of the blend: the ratio of carbon content = 1.2 is mixed evenly, and gasification is carried out at 900°C; the diameter of the particles is between 4-10mm;

[0040] (2) Before catalytic reforming, the tar gas produced by blending gasification enters the high-temperature cracking furnace for thermal cracking. After cracking at 1000°C for 20 seconds, most of the tar is fully decomposed at this stage;

[0041] (3) The undecomposed tar gas and water vapor in the high-temperature cracking stage enter the catalytic furnace for catalytic decomposition, and olivine particles are used as catalysts, and low-molecular hydrocarbons are reformed and transformed into H ...

Embodiment 3

[0045] The method for producing hydrogen by blending gasification of sludge and biomass described in this example is as follows:

[0046] (1) Dewater the municipal sludge. After dehydration, it does not need to be dried and blended with plastic granules to make granules for gasification; the mixing ratio of the granules is to dehydrate the dehydrated municipal sludge and plastic granules according to the water content of the blend. : The ratio of carbon content = 1.5 is mixed evenly, and gasified at 950°C; the diameter of the particles is between 4-10mm;

[0047] (2) Before the catalytic reforming, the tar gas produced by the blended gasification enters the high-temperature cracking furnace for thermal cracking. After cracking at 1100°C for 10 seconds, most of the tar is fully decomposed at this stage;

[0048] (3) The incompletely decomposed tar gas and water vapor in the high-temperature cracking stage enter the catalytic furnace for catalytic decomposition, using supported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com