Labyrinth type oil-gas separation chamber with additionally mounted turbine

A technology of oil and gas separation chamber and oil and gas separator, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve the problems of reducing the lubricating effect of engine oil in the crankcase, increasing the PM emission of the engine, and damaging the air filter element and other problems, to achieve the effect of increasing flow rate, increasing pressure and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to the oil-gas separation structure design of a cam chamber in the engine crankcase ventilation, and aims to provide a simple and effective oil-gas separation chamber structure.

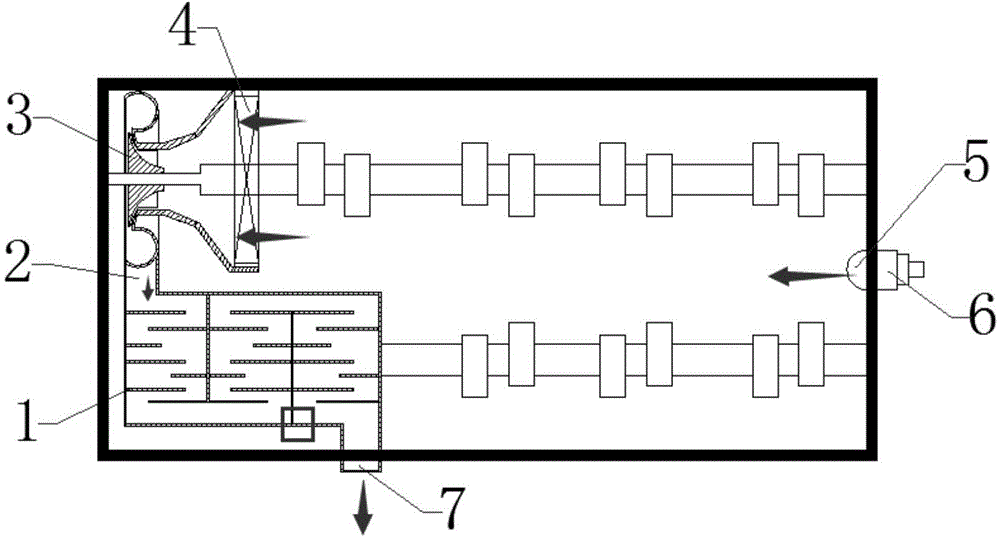

[0018] Such as figure 1 As shown, the structure mainly includes a labyrinth oil-gas separator 1, a pressure regulating valve 6, a non-woven filter element 4 and a turbine 3:

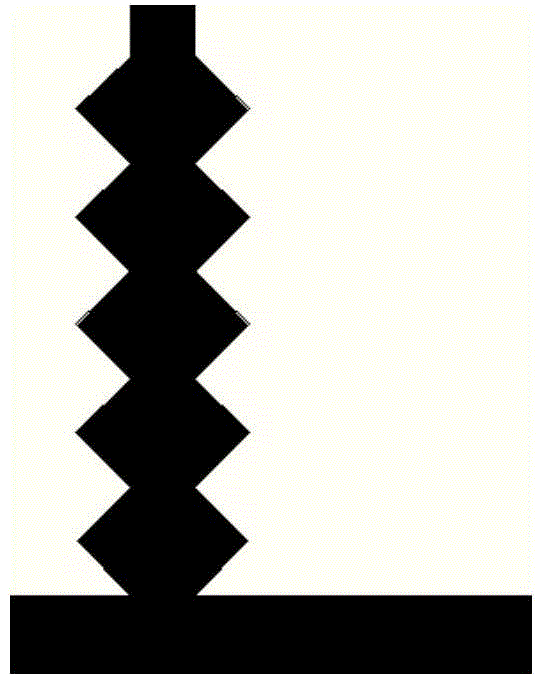

[0019] The labyrinth oil-gas separator has a toothed baffle made of engineering plastics, which is assembled inside the cylinder head in a certain structural design and connected to the turbine outlet to increase the impact of the oil particles in the mixed oil mist on the wall. Probability, can make the oil particles condense, adhere and merge, and return the oil through the oil return tank, and the outlet of the oil-gas separator can also be connected to other oil-gas separation devices outside the machine to further improve the oil-gas separation efficiency.

[0020] The pressure regulating valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com