Patents

Literature

69results about How to "Protection form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

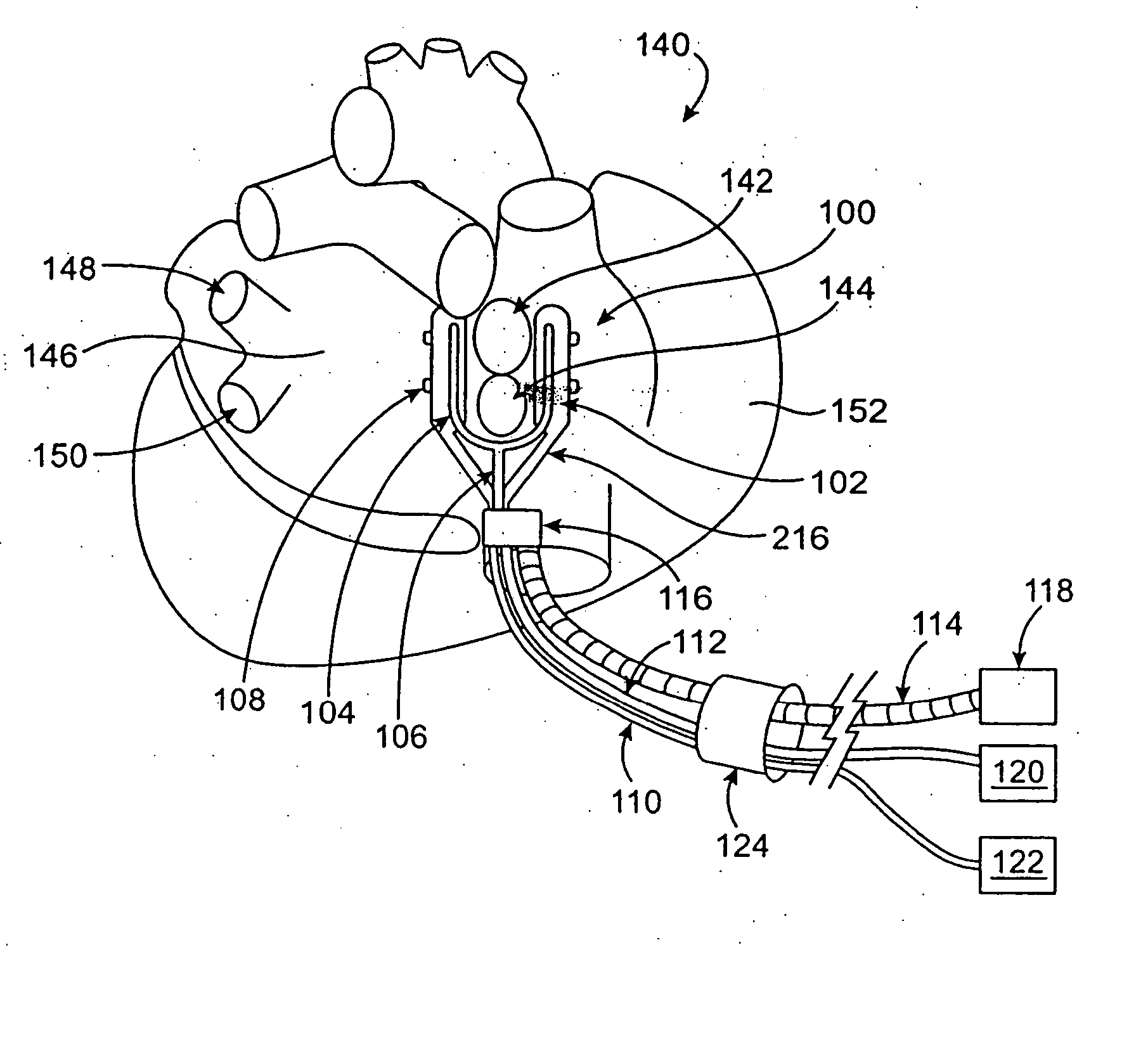

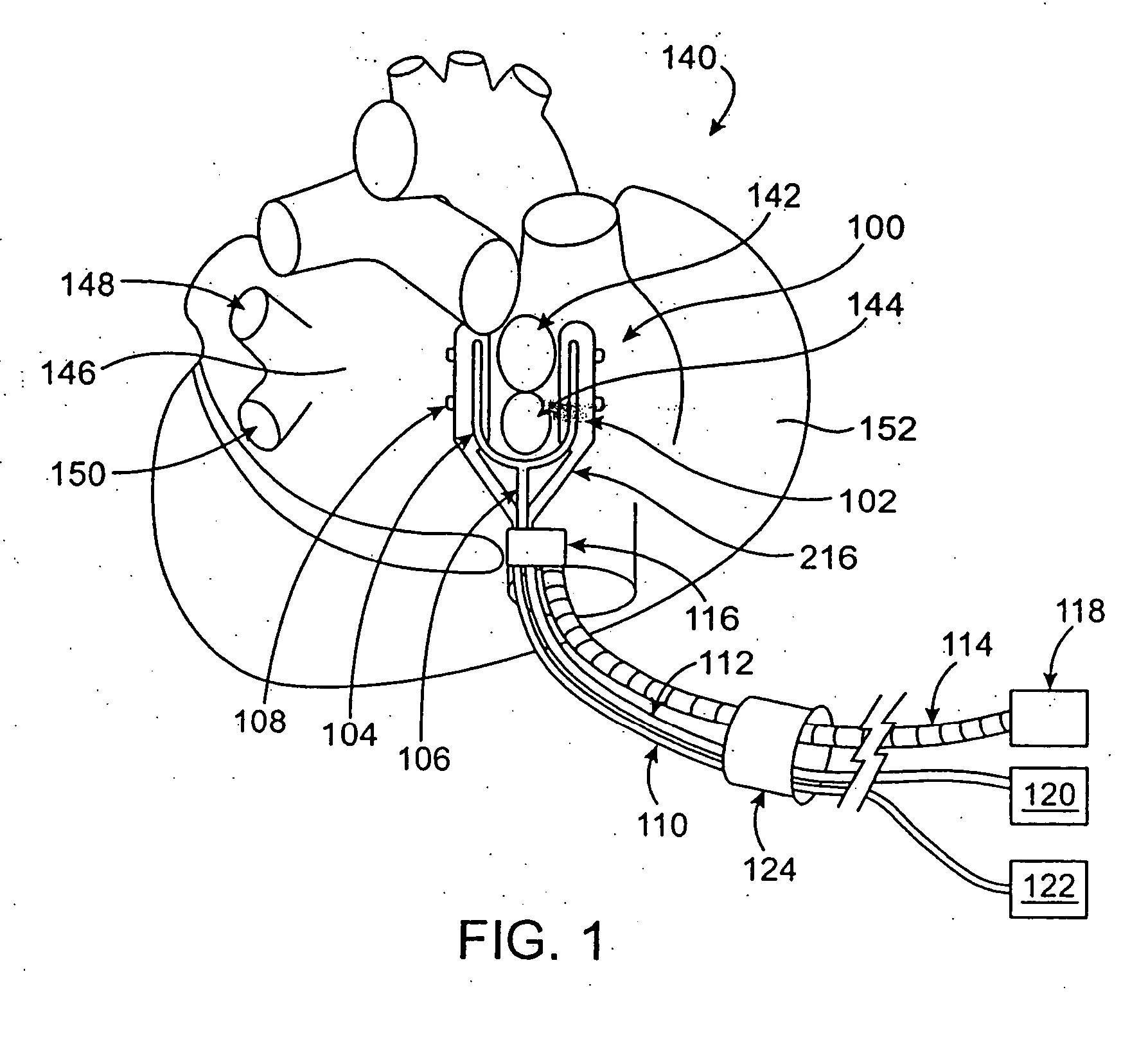

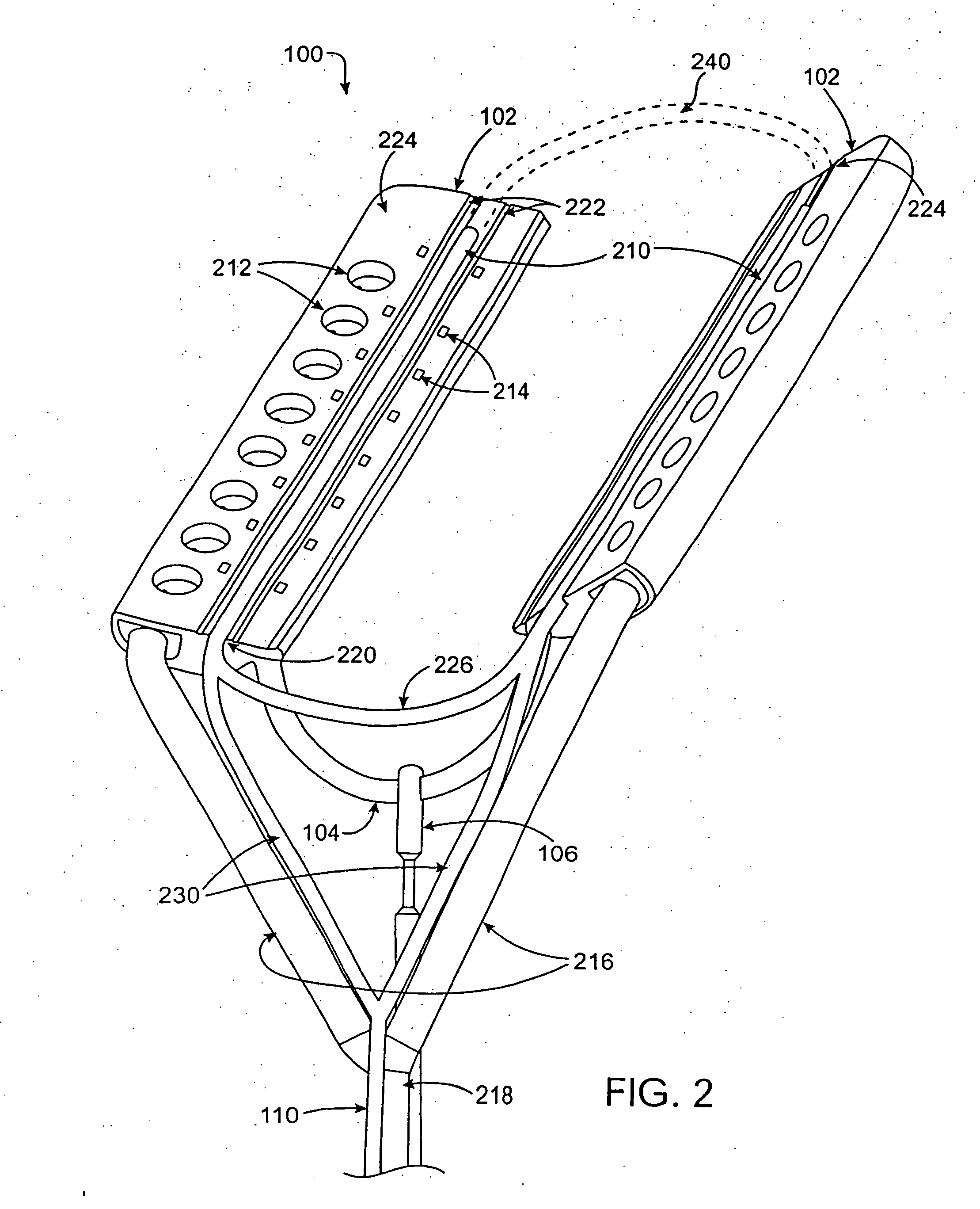

Cardiac ablation devices and methods

ActiveUS20050149152A1Lower impedanceImprove conductivityEpicardial electrodesSurgical needlesAtrial cavityCardiac arrhythmia

Devices and methods provide for ablation of cardiac tissue for treating cardiac arrhythmias such as atrial fibrillation. Although the devices and methods are often be used to ablate epicardial tissue in the vicinity of at least one pulmonary vein, various embodiments may be used to ablate other cardiac tissues in other locations on a heart. Devices generally include at least one tissue contacting member for contacting epicardial tissue and securing the ablation device to the epicardial tissue, and at least one ablation member for ablating the tissue. Various embodiments include features, such as suction apertures, which enable the device to attach to the epicardial surface with sufficient strength to allow the tissue to be stabilized via the device. For example, some embodiments may be used to stabilize a beating heart to enable a beating heart ablation procedure. Many of the devices may be introduced into a patient via minimally invasive introducer devices and the like. Although devices and methods of the invention may be used to ablate epicardial tissue to treat atrial fibrillation, they may also be used in veterinary or research contexts, to treat various heart conditions other than atrial fibrillation and / or to ablate cardiac tissue other than the epicardium.

Owner:ATRICURE

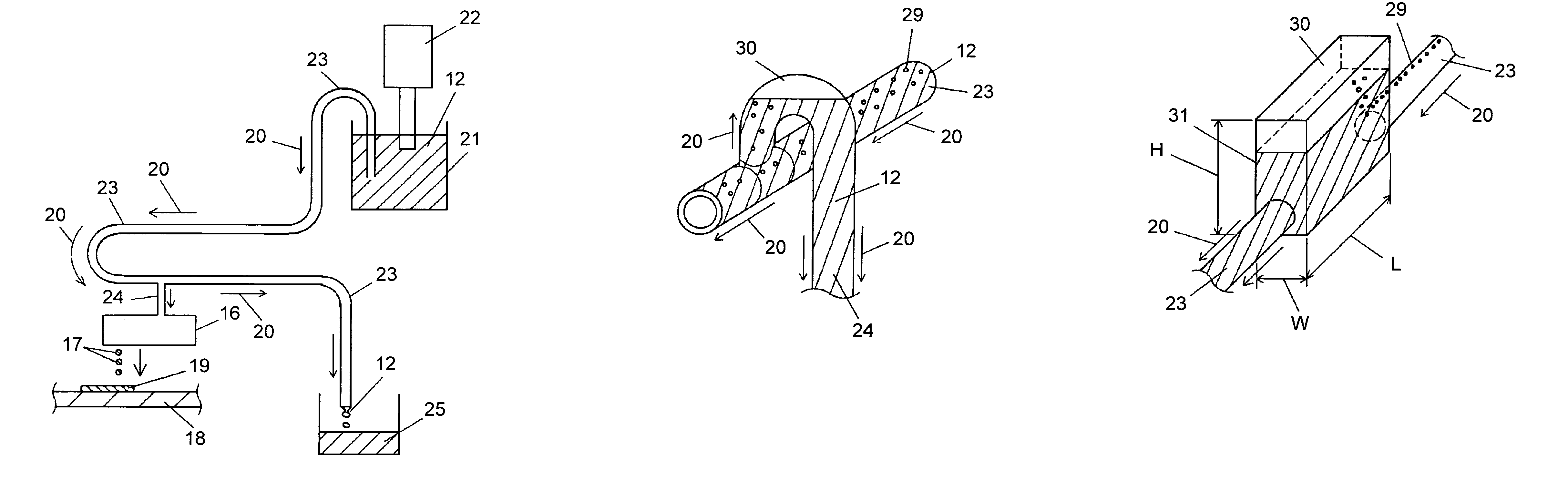

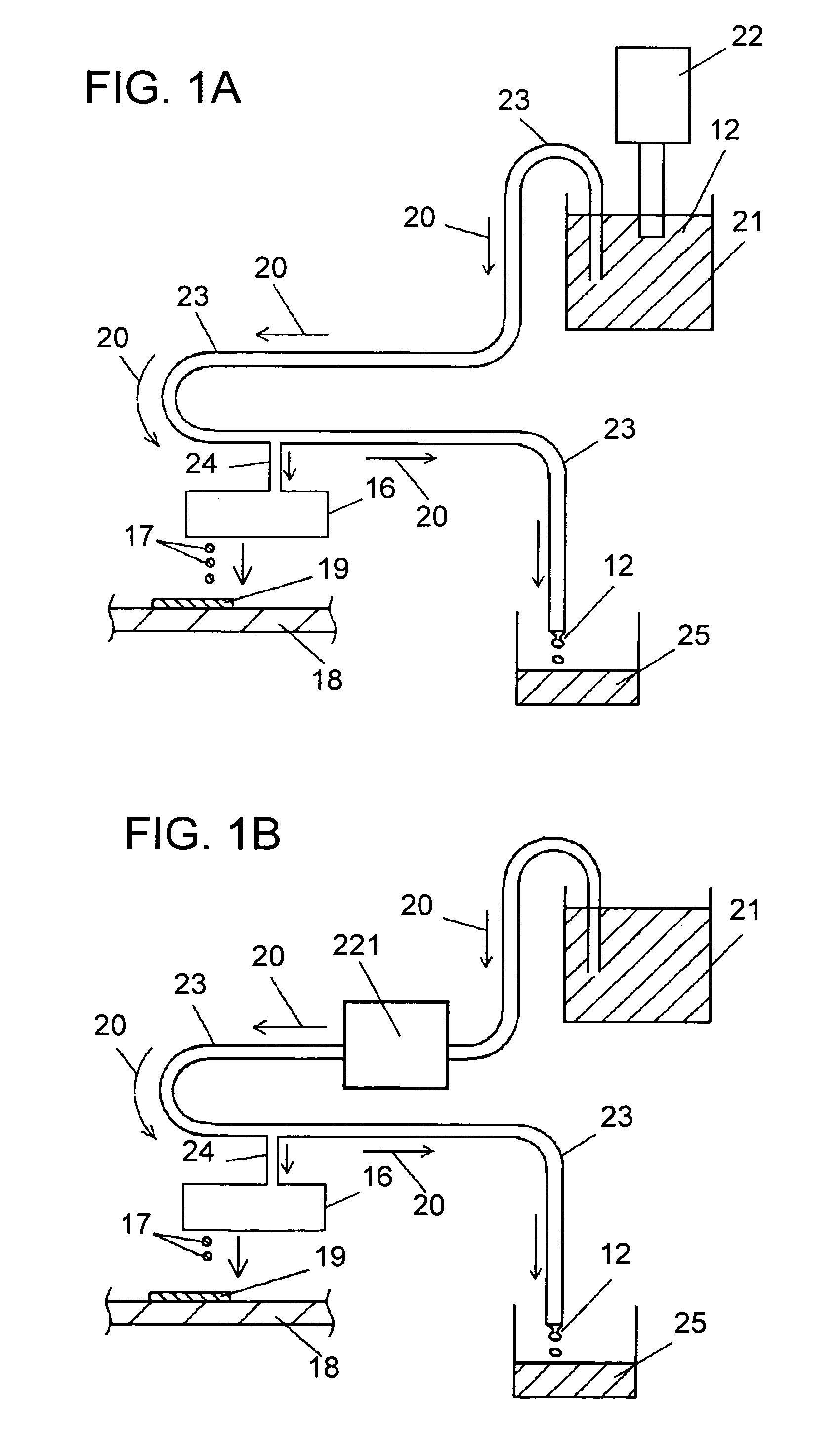

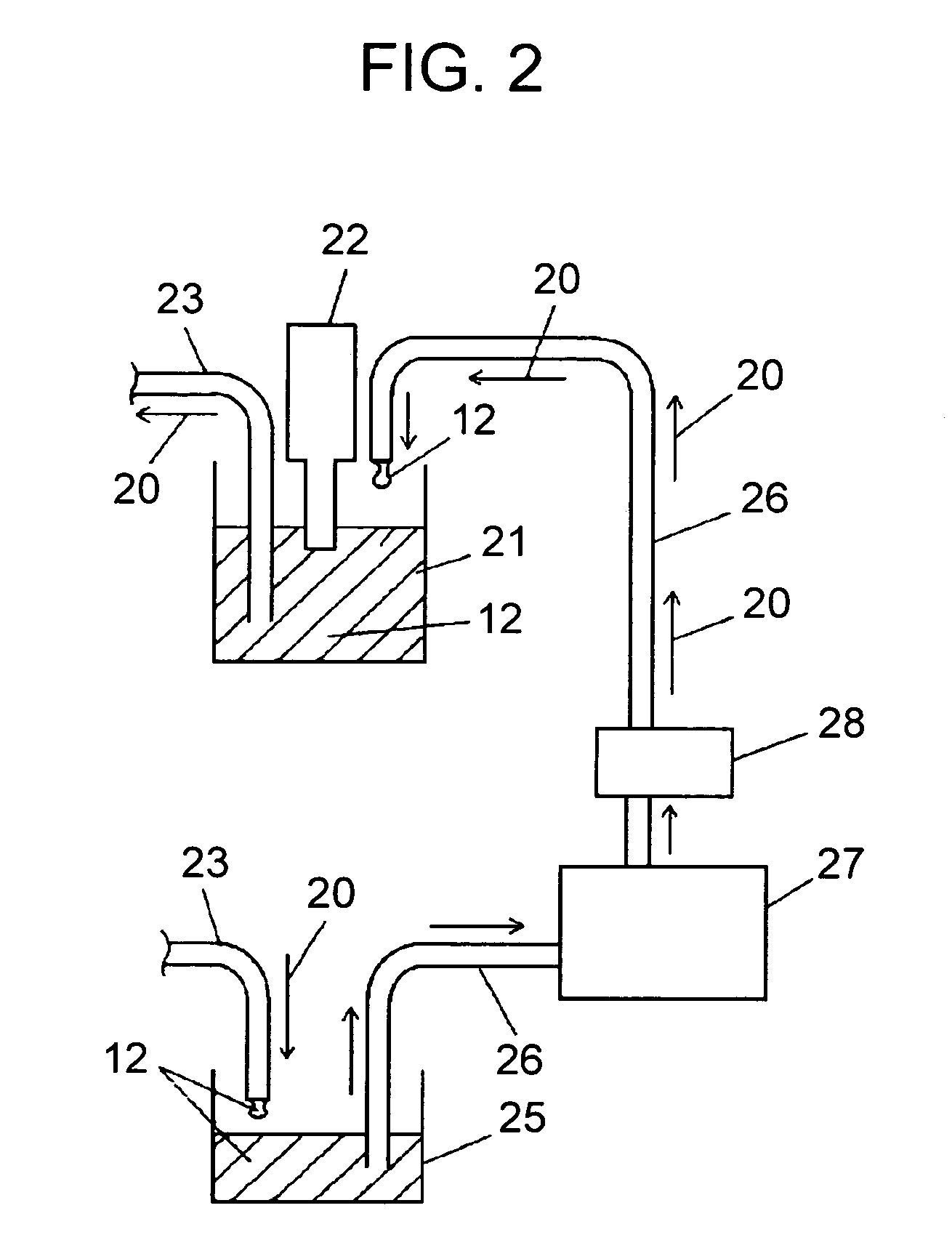

Ink jet device, ink jet ink, and method of manufacturing electronic component using the device and the ink

InactiveUS7097287B2Ink jet printing with stabilityReduced stabilityFixed capacitorsNon-conductive material with dispersed conductive materialEngineeringElectronic component

Owner:PANASONIC CORP

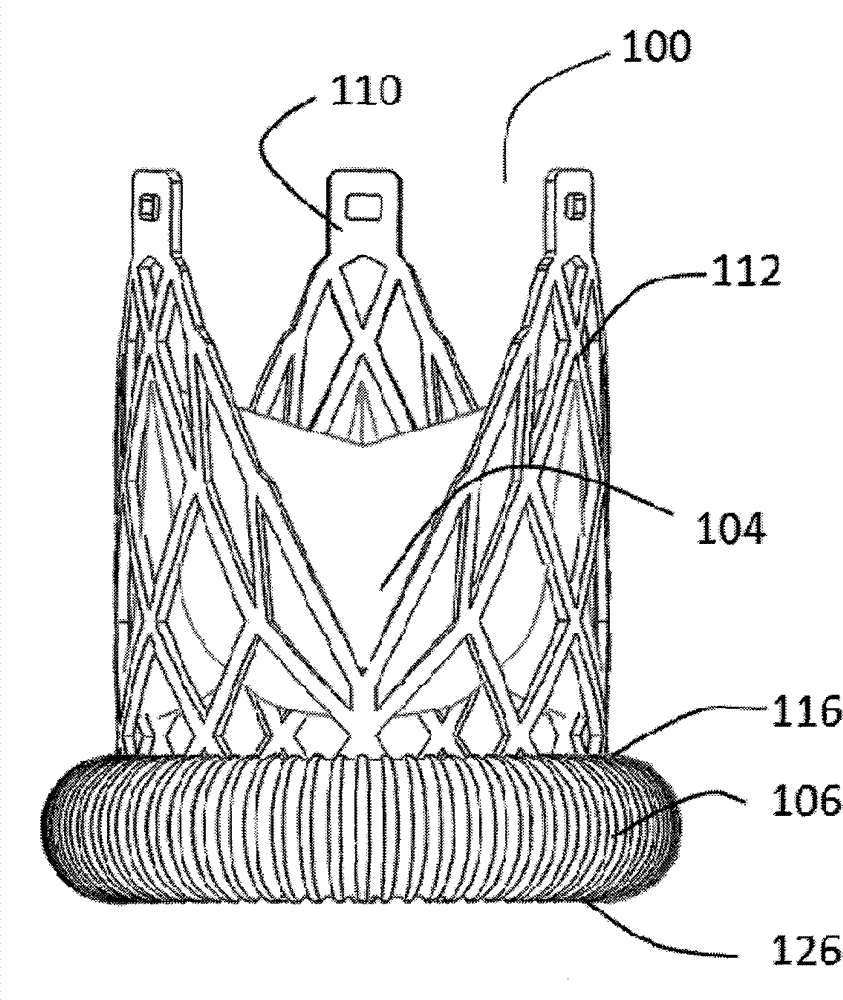

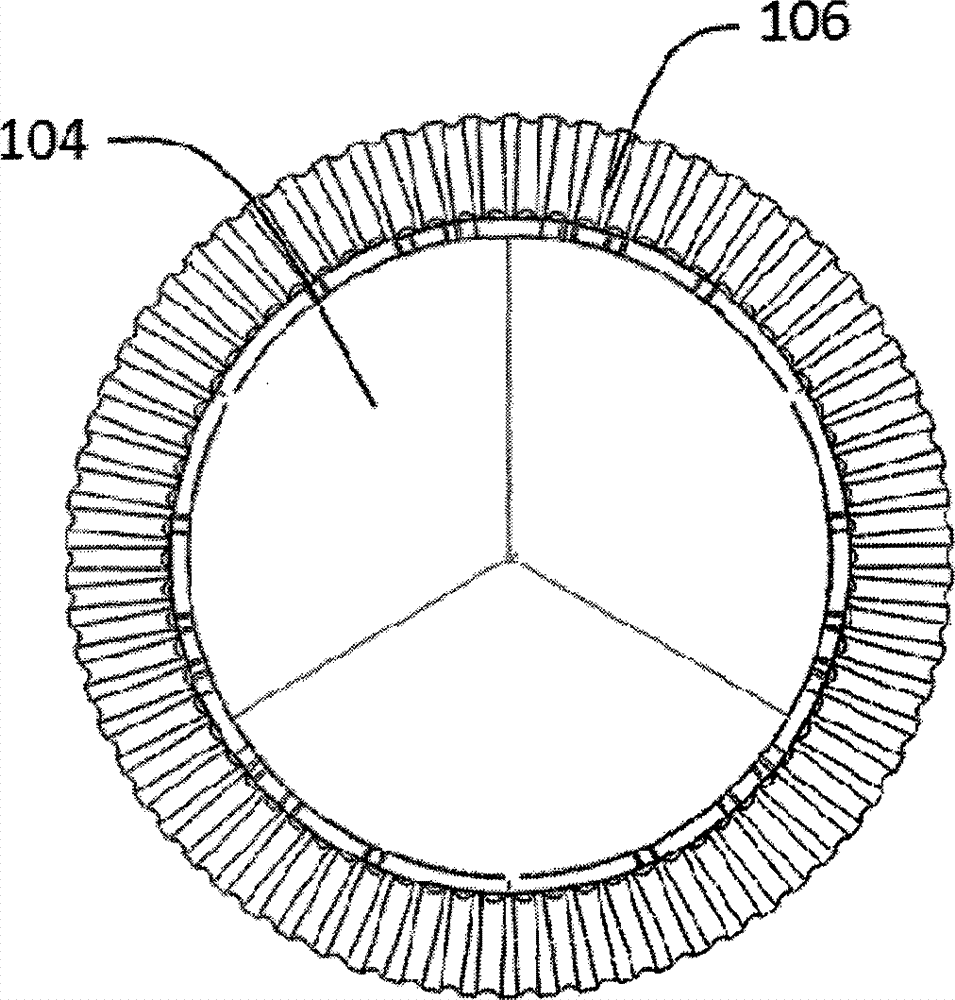

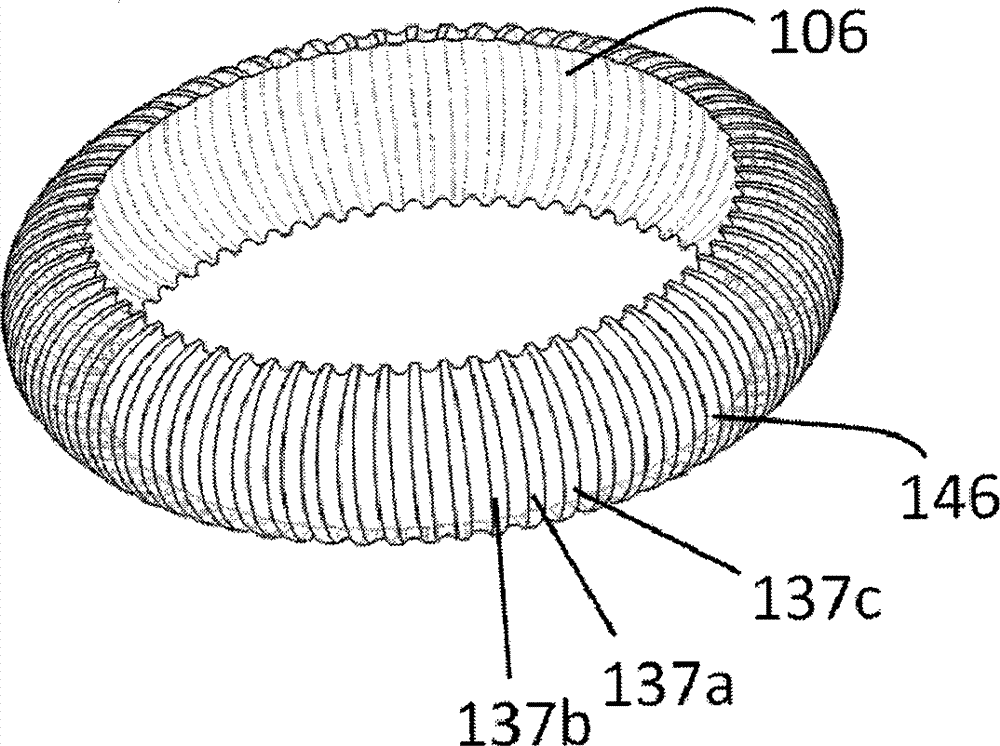

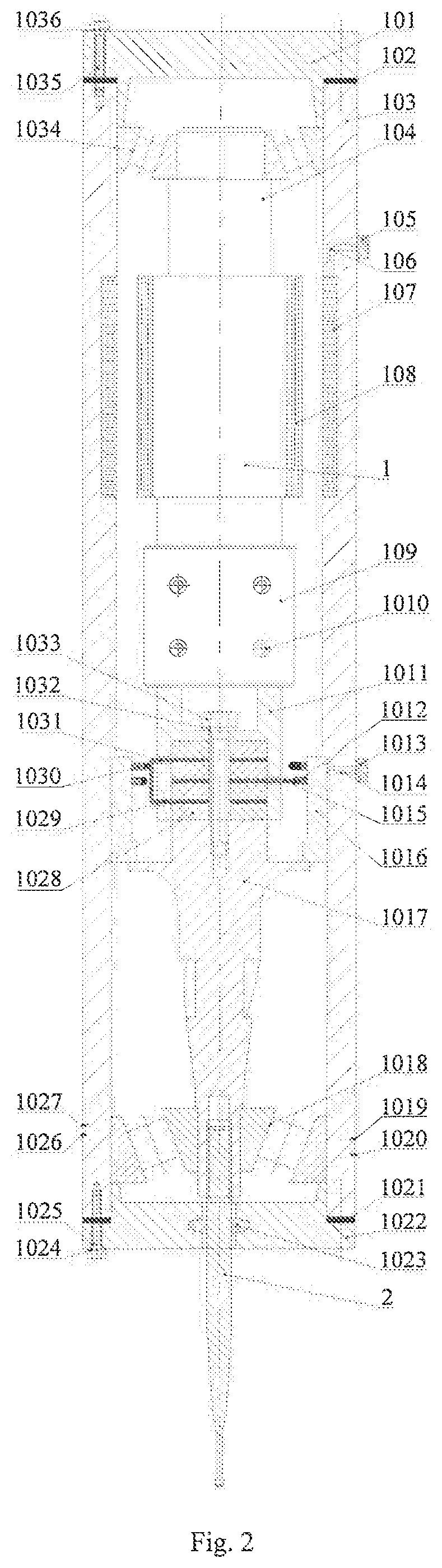

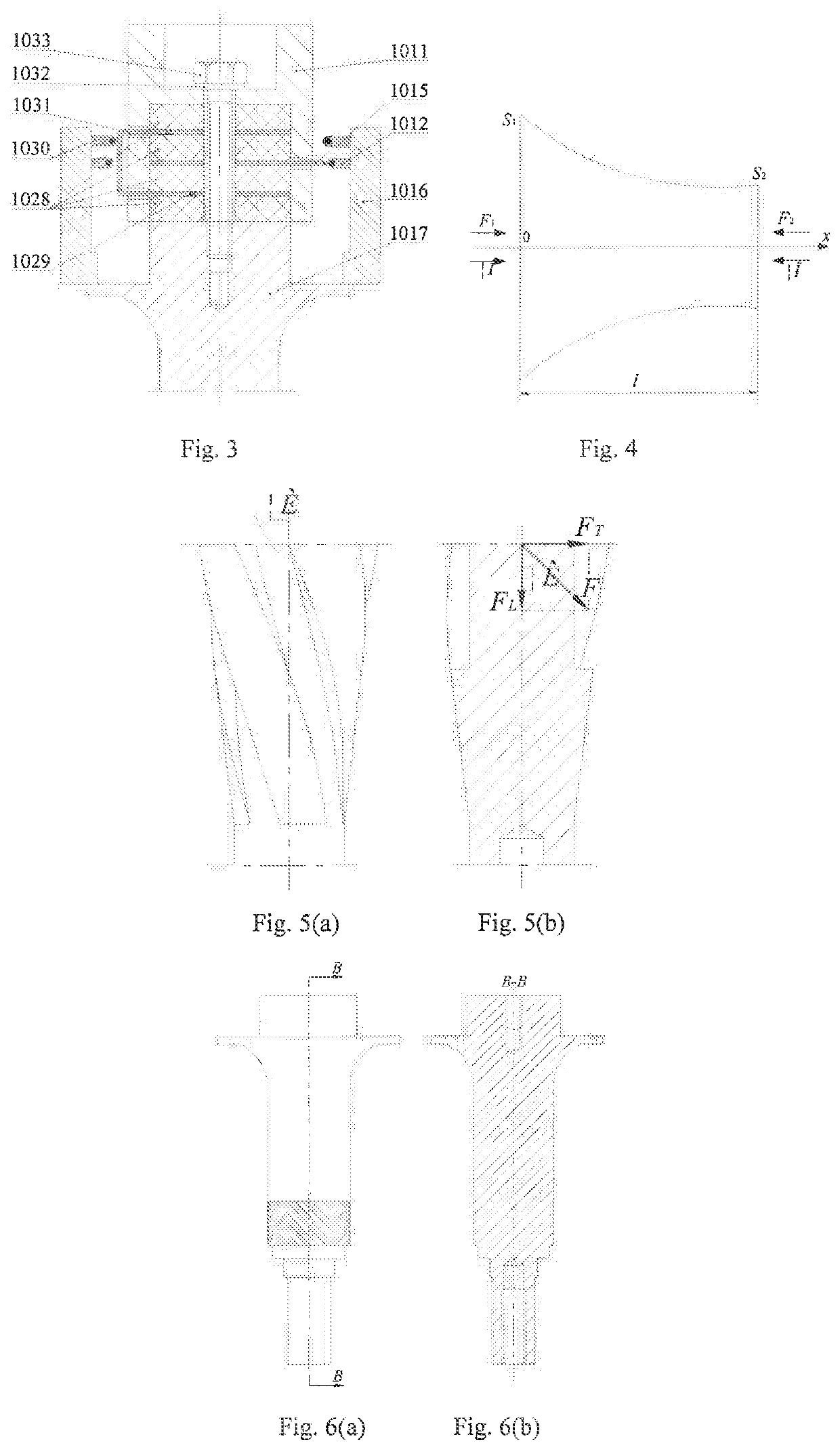

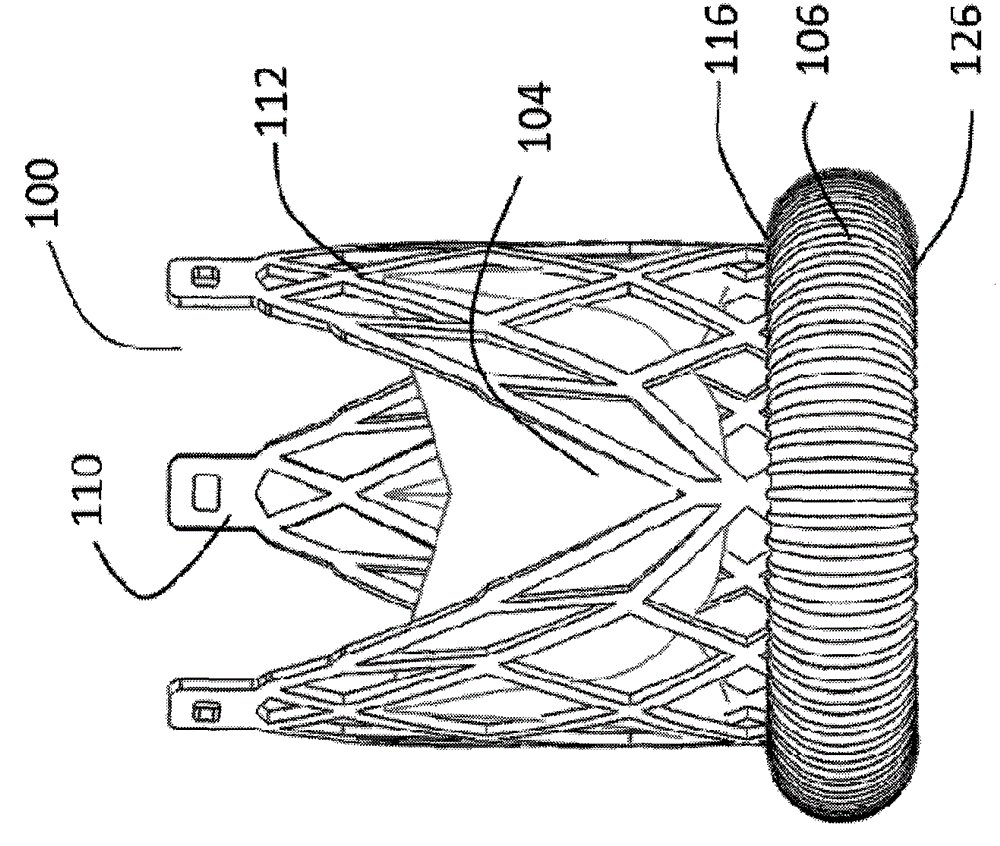

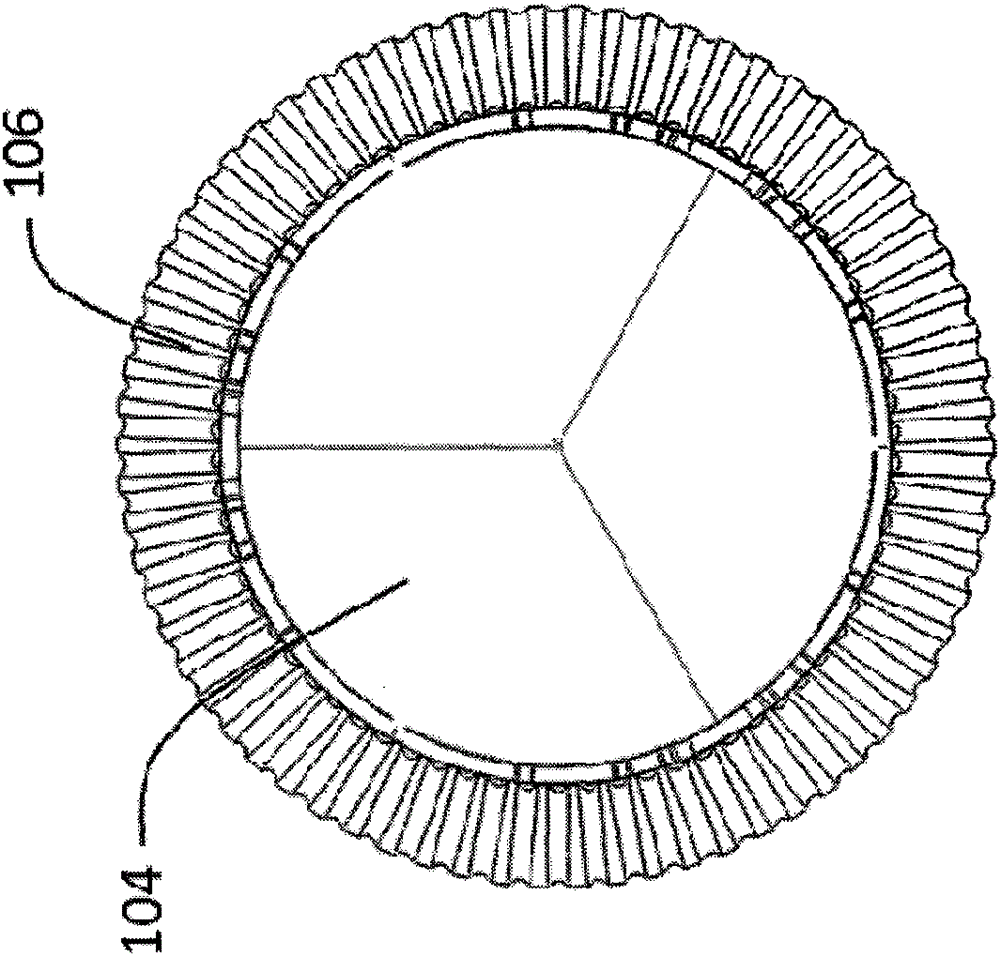

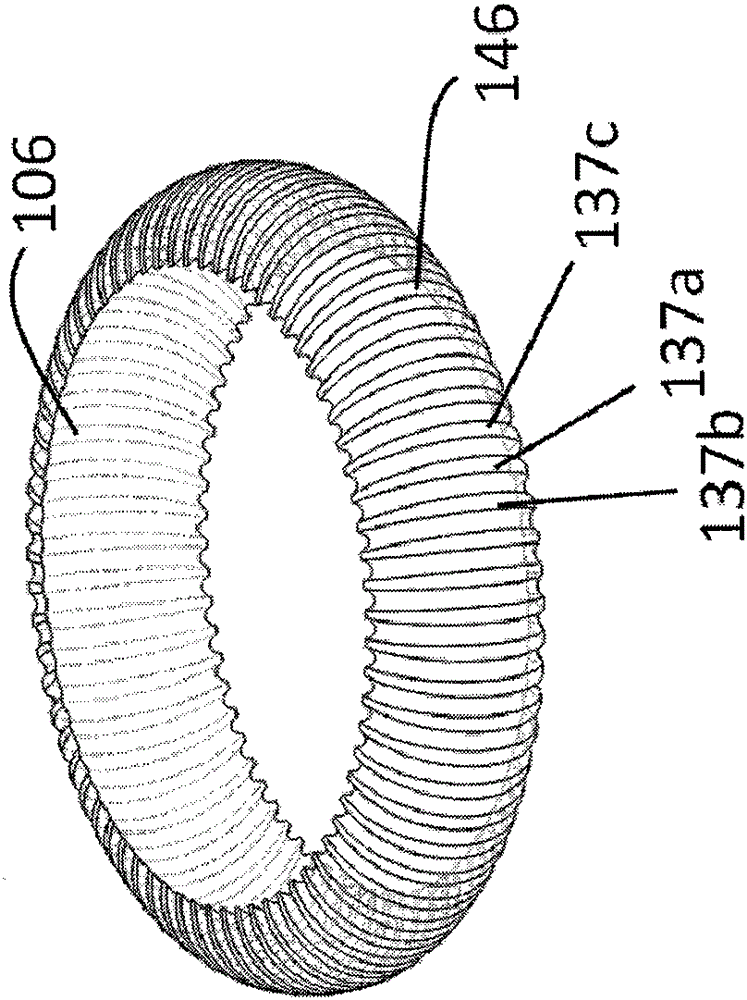

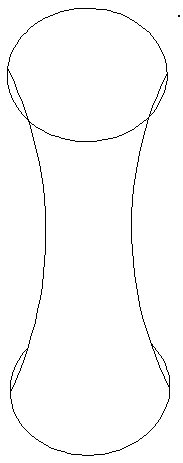

Aortic valve stent capable of preventing perivalvular leakage

ActiveCN103705315AImprove complianceExcellent shape memory performanceHeart valvesProsthetic valveNatural state

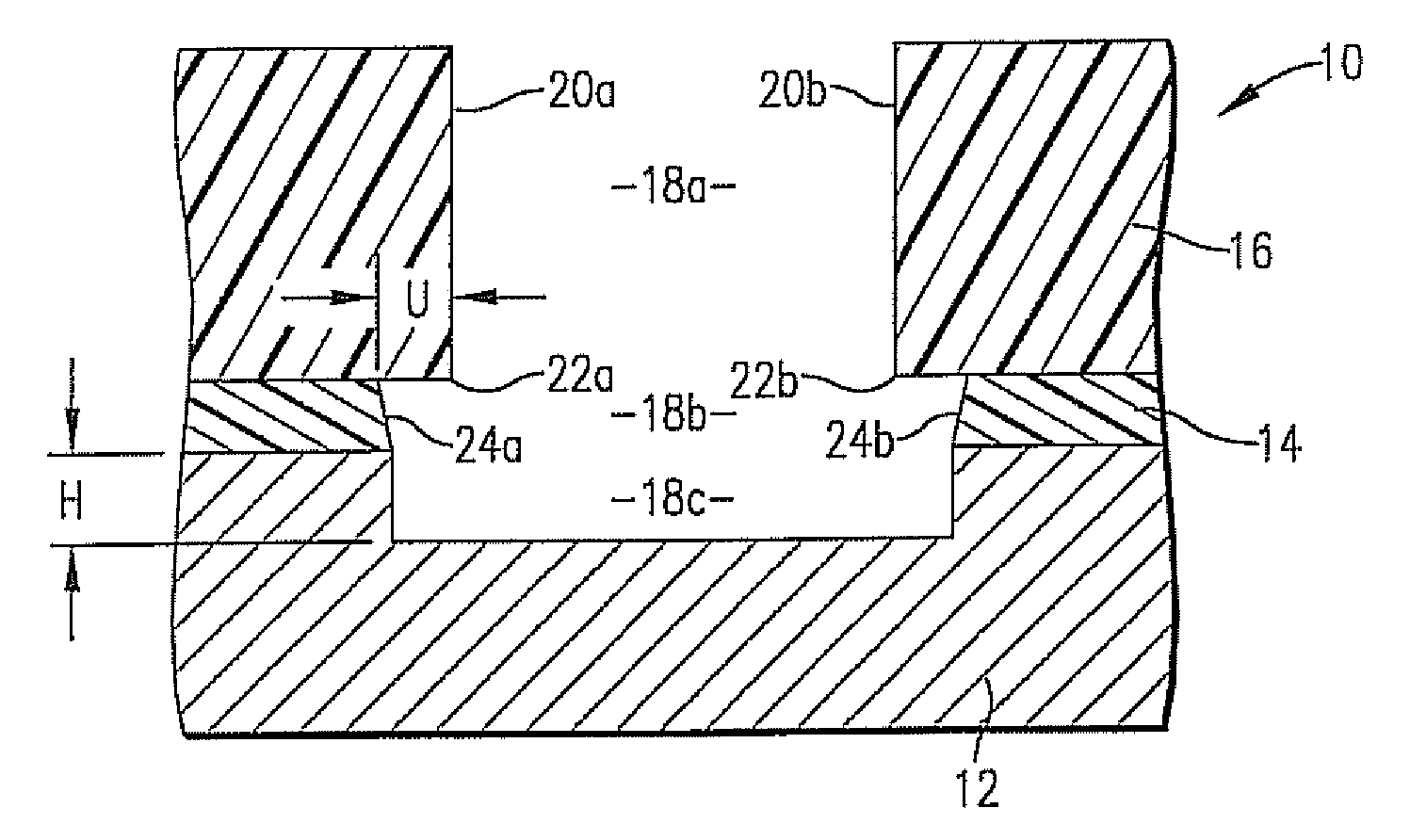

The invention discloses an aortic valve stent (100) capable of preventing perivalvular leakage. The aortic valve stent (100) capable of preventing perivalvular leakage comprises a stent (110) and an artificial valve (104), wherein the stent (110) is composed of a plurality of grid cells (112); the artificial valve (104) is connected to the grid cells (112); a sealing unit (106) is arranged at the bottom of the stent (110); the sealing unit (106) is made from a metal memory material and laminated; in a natural state, the sealing unit (106) is arched outwards along the axial direction of the stent and of an annular structure along the peripheral direction of the stent (110); one end of the sealing unit (106) is free and is a free end (116); the other end of the sealing unit (106) is fixed with the bottom of the stent (110) by a fixing element, and is a fixed end (126); when the sealing unit (106) is compressed to enter a sheathing canal, the free end (116) of the sealing unit (106) turns towards the bottom end of the stent and around the fixed end (126), thus the sealing unit (106) is not superposed with the stent (110).

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

Combination used for preventing and treating newborn pig diarrhea and preparation method and application thereof

The invention discloses a combination used for preventing and treating newborn piglet diarrhea and a preparation method and application thereof. In percent by weight, the product comprises 88-98% of attapulgite ultra-fine powder, 0.1-3% of organic acid, 0.1-4% of probiotic, 0.05-2% of oligosaccharide, 0.05-1.5% of vitamin C and 0.15-3% of crane sugar. The combination disclosed by the invention isdiluted into solution with the mass fraction of 0.05-3% with drinking water, the solution is used for feeding a piglet in an oral or drinking water manner, and the newborn piglet diarrhea caused by multiple factors can be effectively prevented and treated, thus the combination has the effects of improving immunocompetence of the piglet, improving antioxidant function, regulating intestinal microecology and protecting intestinal shape and can improve survival rate of the piglet, improve production performance of the piglet and relieve weaned stress on the piglet. The combination disclosed by the invention also has the characteristics of simple and convenient application mode, high efficiency, available raw materials, simple preparation and the like.

Owner:ANYOU BIOTECH GRP

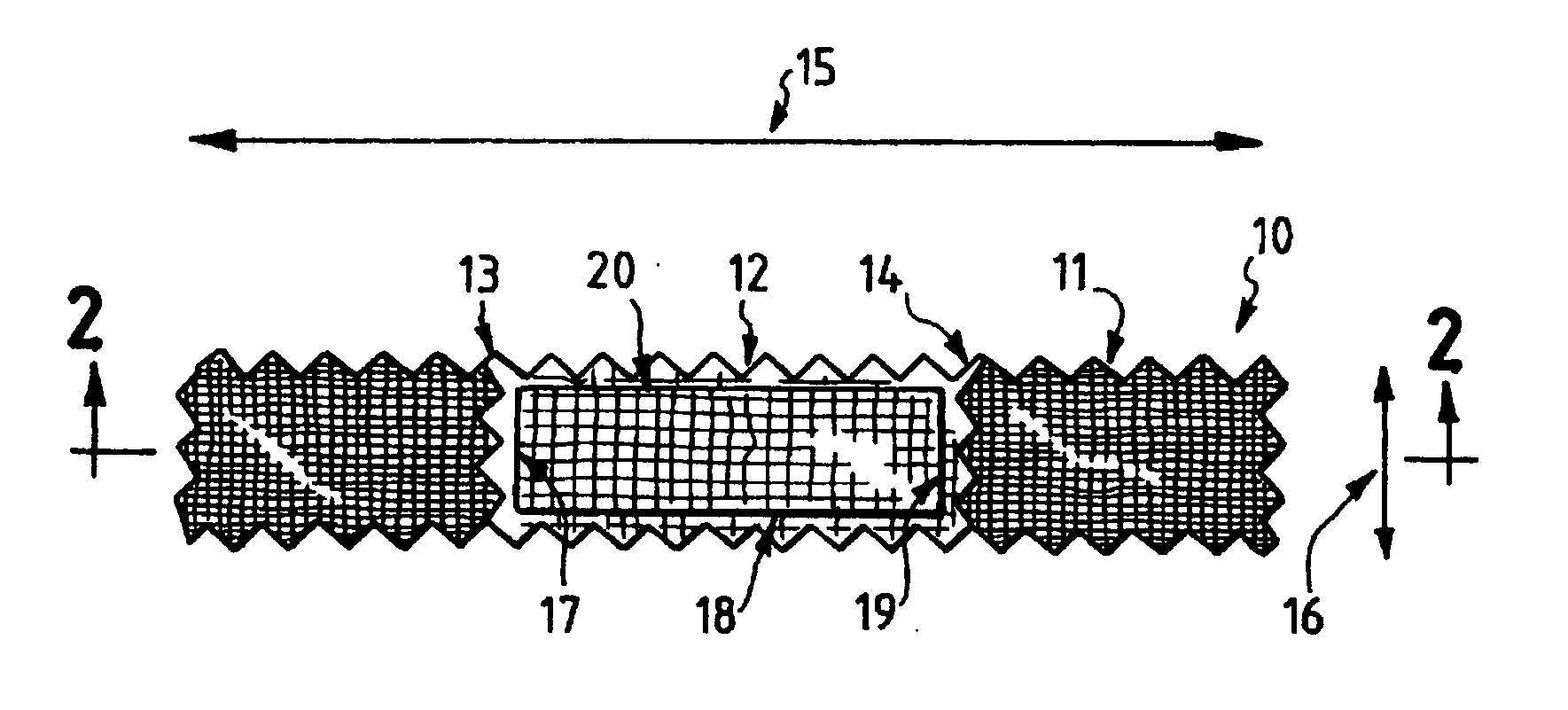

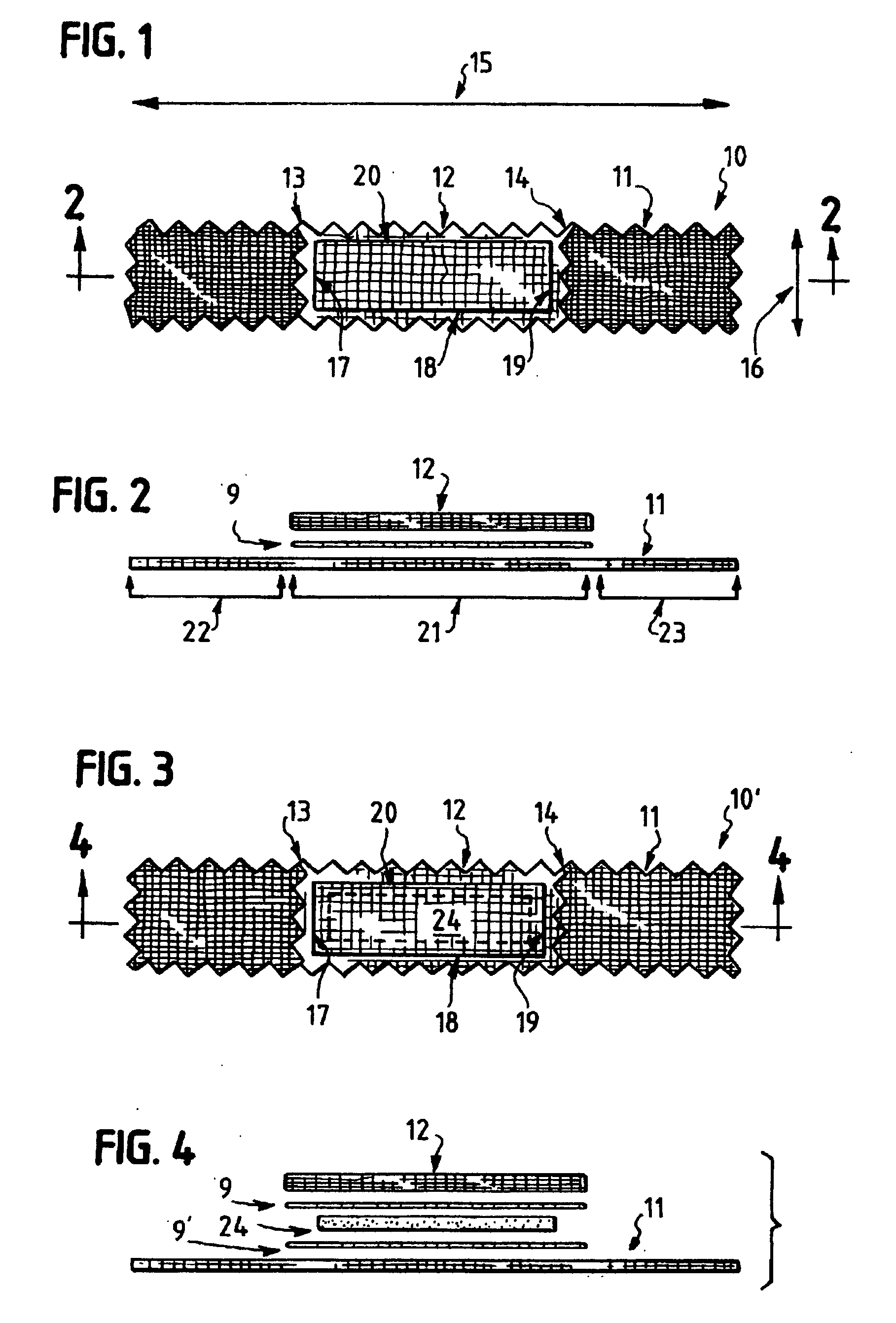

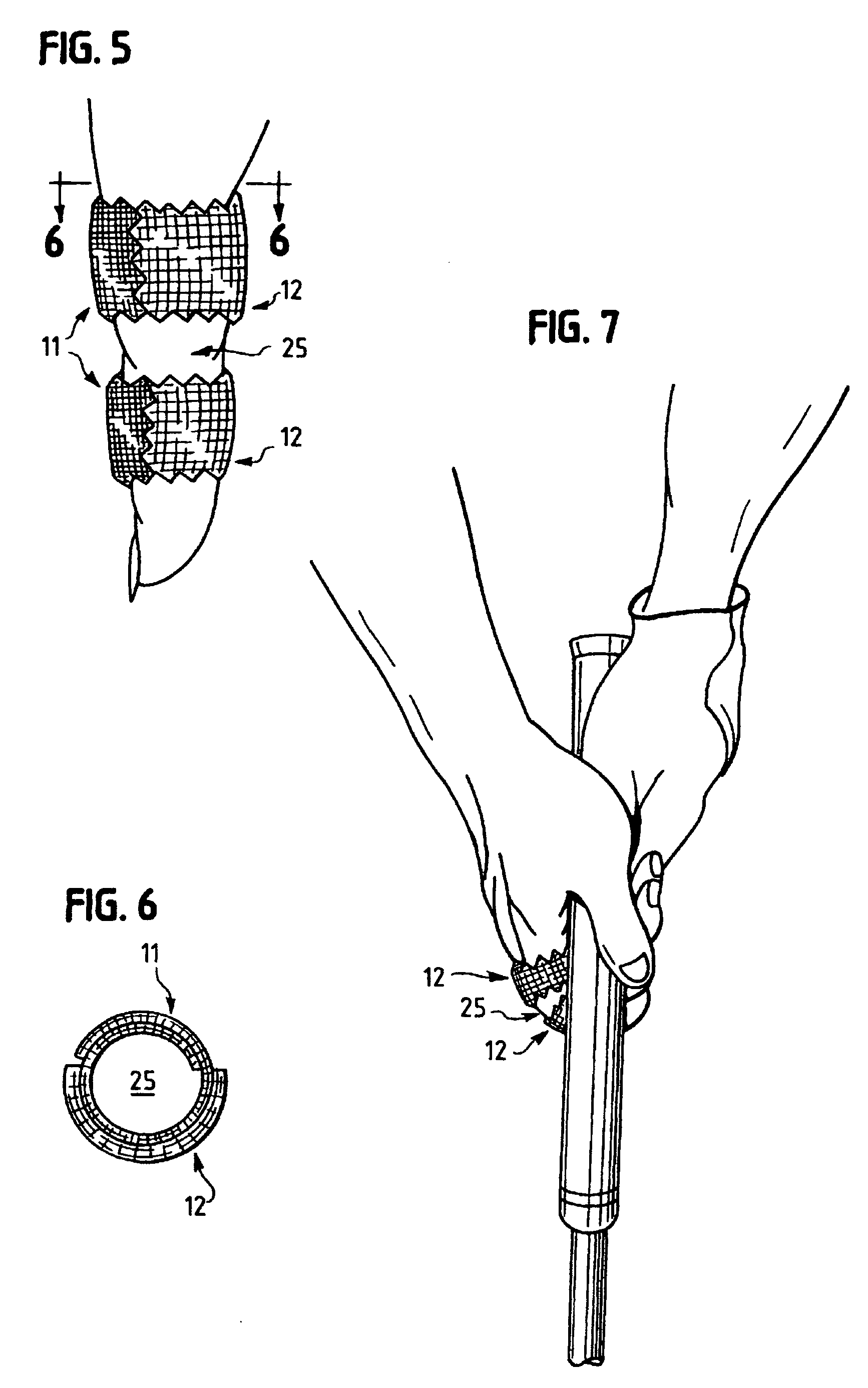

Gripping bandage

InactiveUS20050228331A1Grip controlDifferent lengthFinger bandagesLayered productsSports equipmentEngineering

A grip-aid gripping bandage adopted to be disposed over a finger or glove to protect the finger when using sports equipment or a hand tool and to provide enhanced control when using the sports equipment or hand tool. A first self-adhering strip is provided having a first predetermined length. A second non-self-adhering cushioning strip overlies a portion of and is bonded to the surface of the first self-adhering strip. The entire bandage, including the first self-adhering strip and the second non-self-adhering cushioning strip, provides protection from abrasion and pressure when the bandage is applied to a finger. In a further embodiment, an insert is disposed between the first self-adhering strip and the second non-self-adhering cushioning strip for enhanced protection for the finger.

Owner:TSENG YUNG LUNG +2

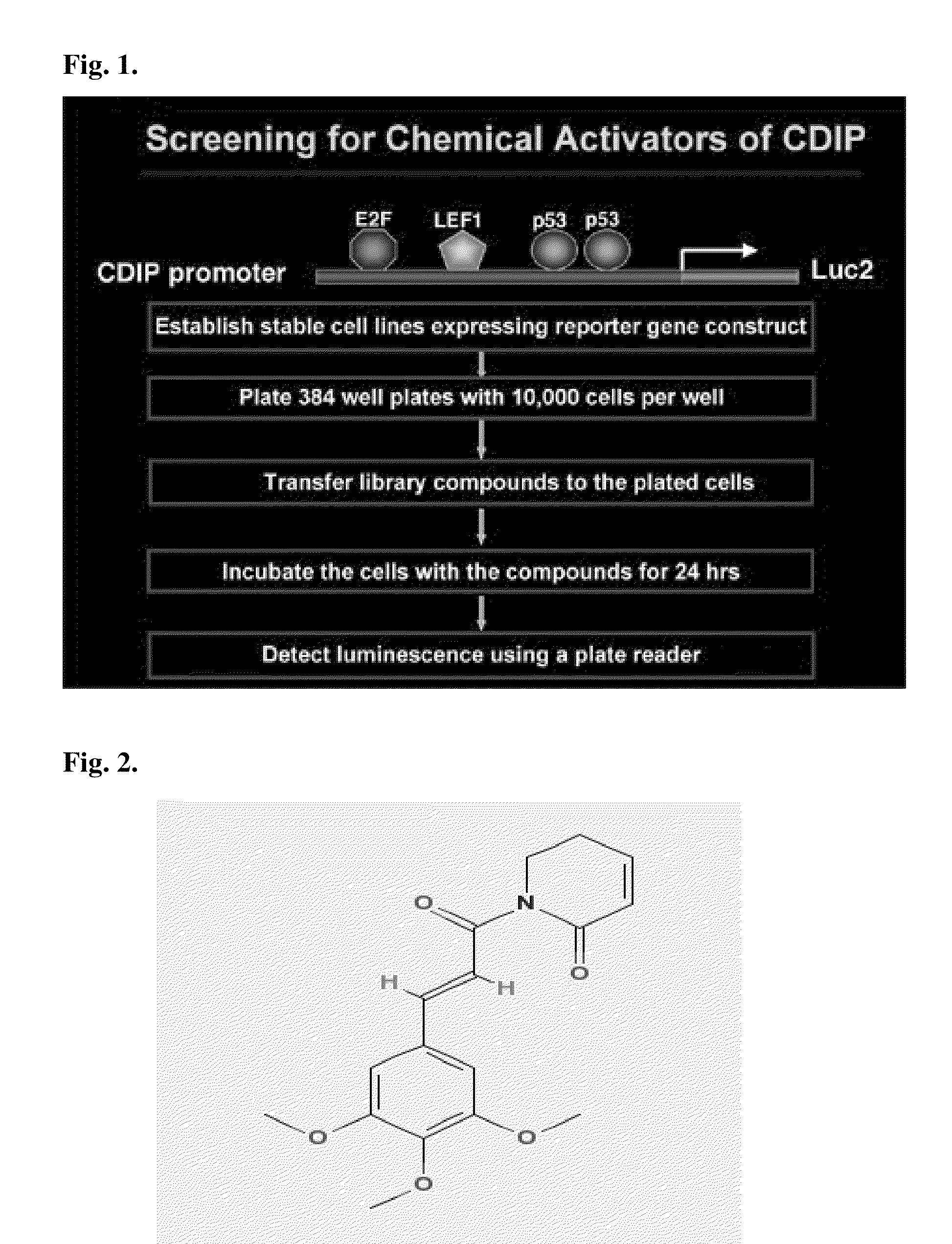

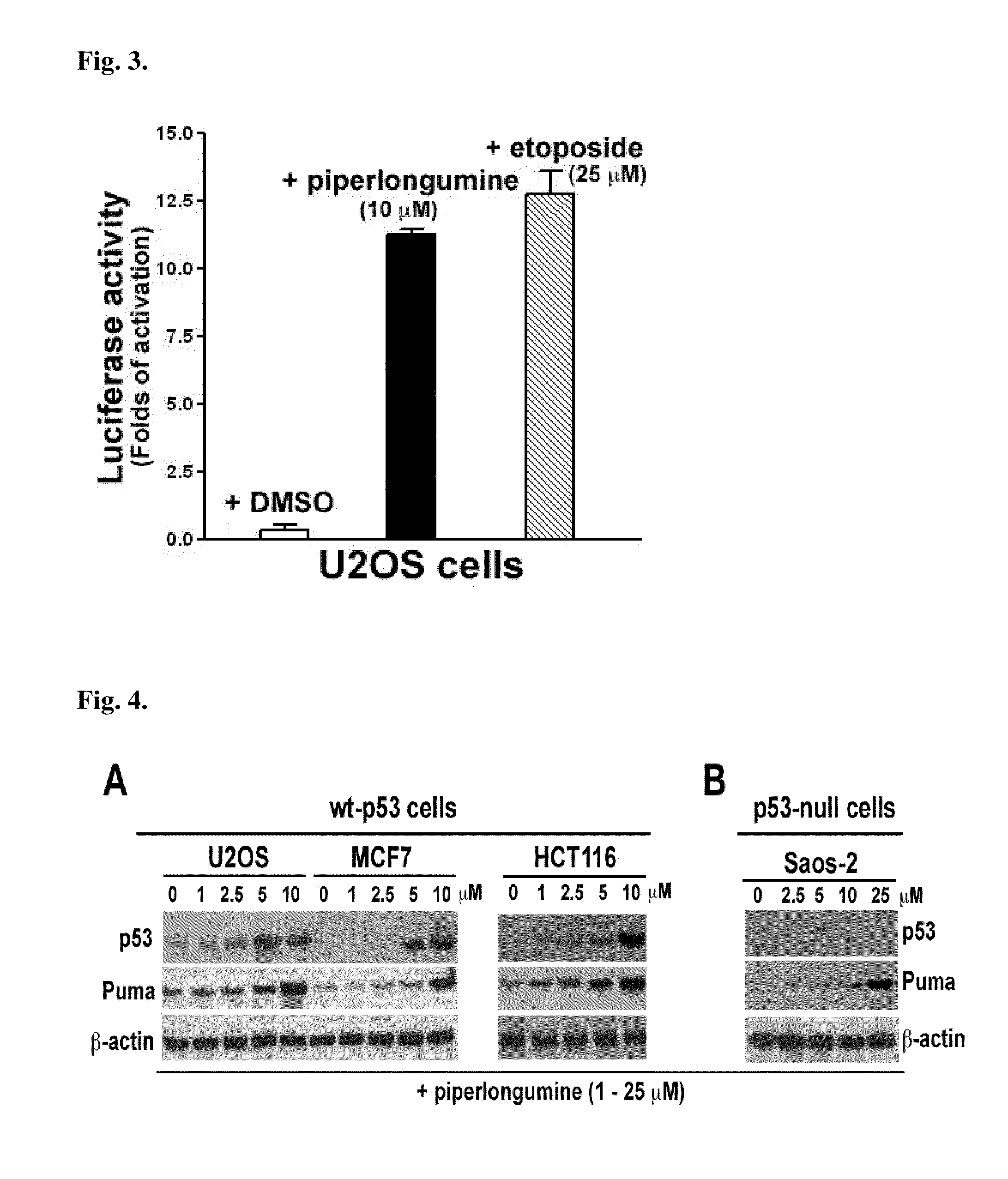

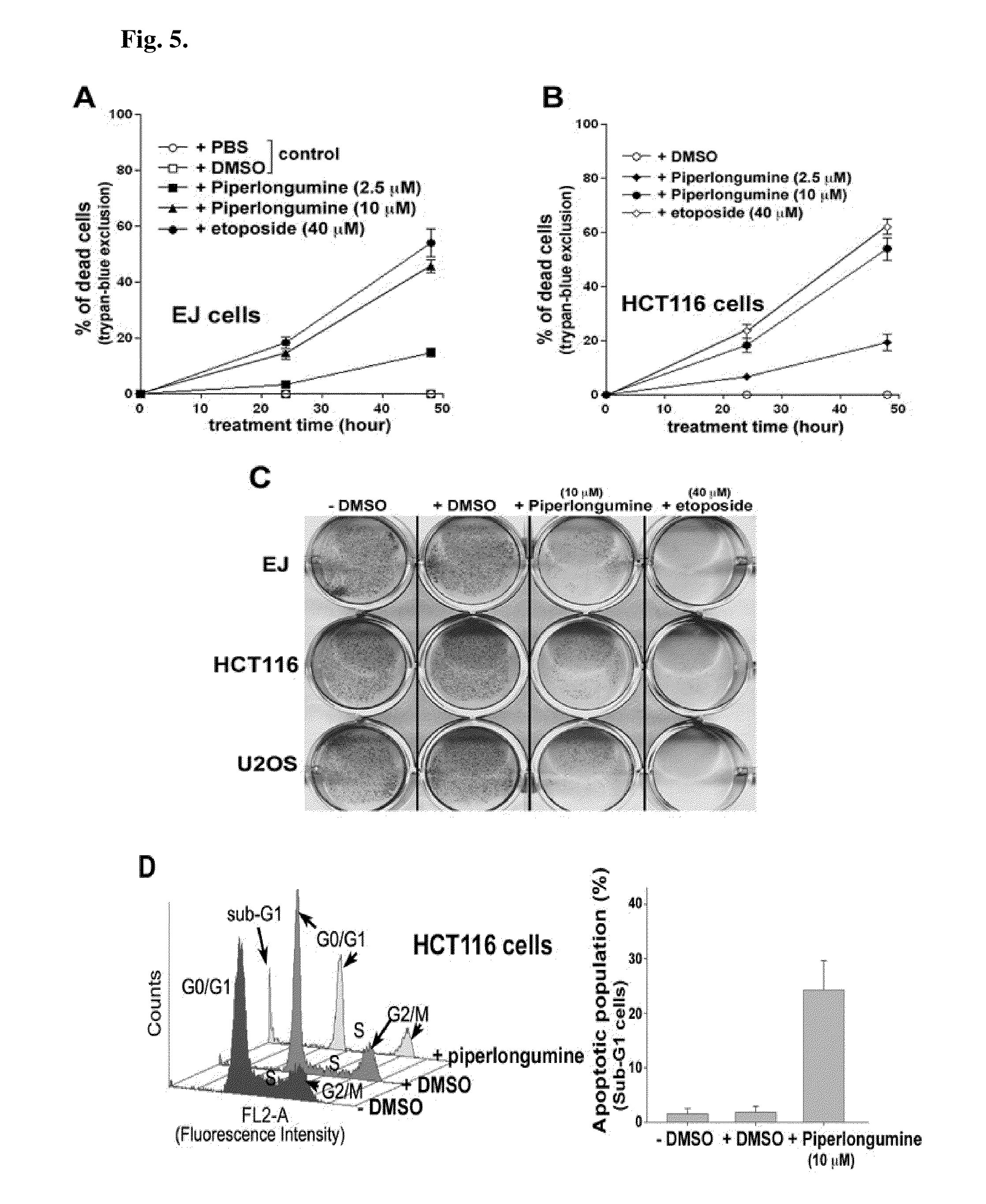

Methods for the treatment of cancer using piperlongumine and piperlongumine analogs

InactiveUS20090312373A1Low toxicitySuppressing accumulation of DNA damageBiocideOrganic chemistryOncologyPiperlongumine

The invention provides methods for the treatment of cancer in a subject using piperlongumine and / or piperlongumine analogs.

Owner:THE GENERAL HOSPITAL CORP

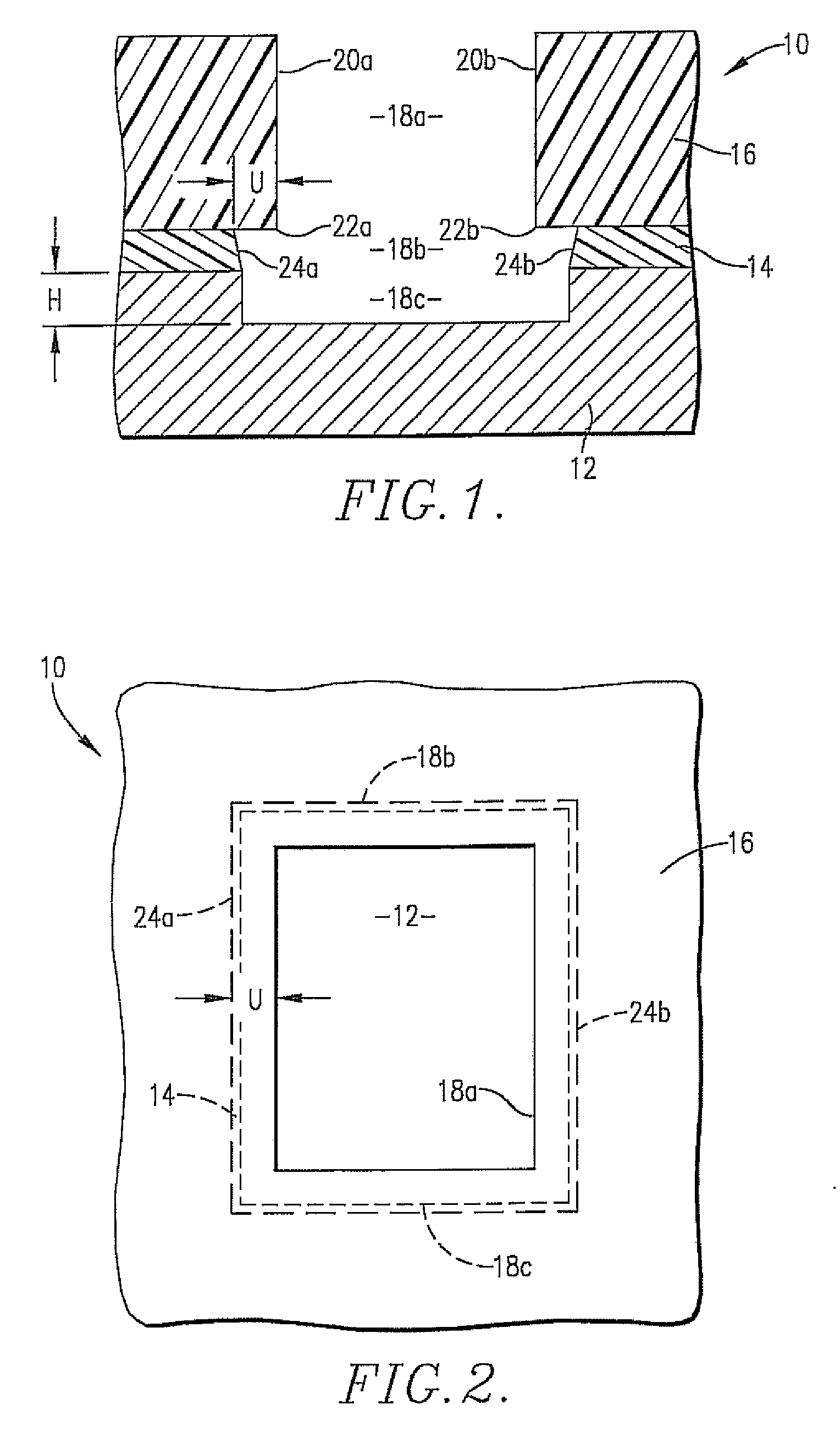

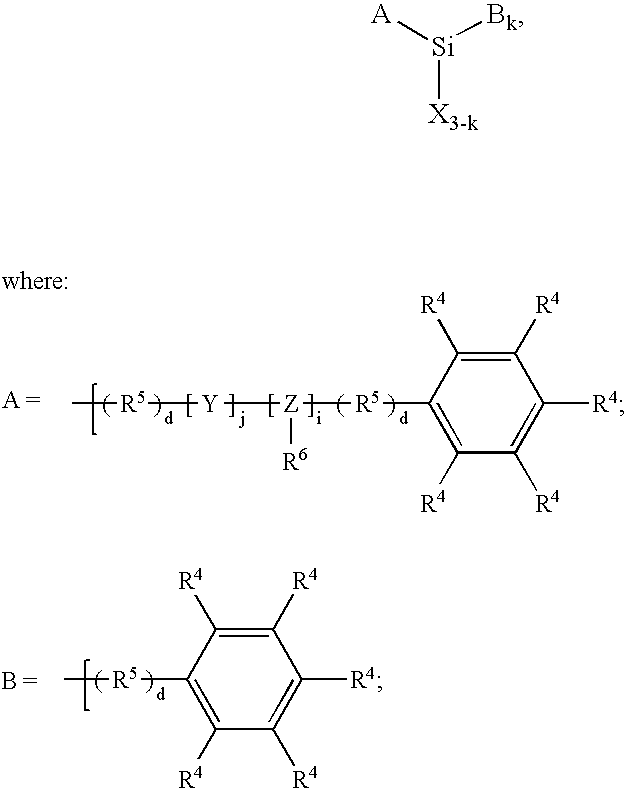

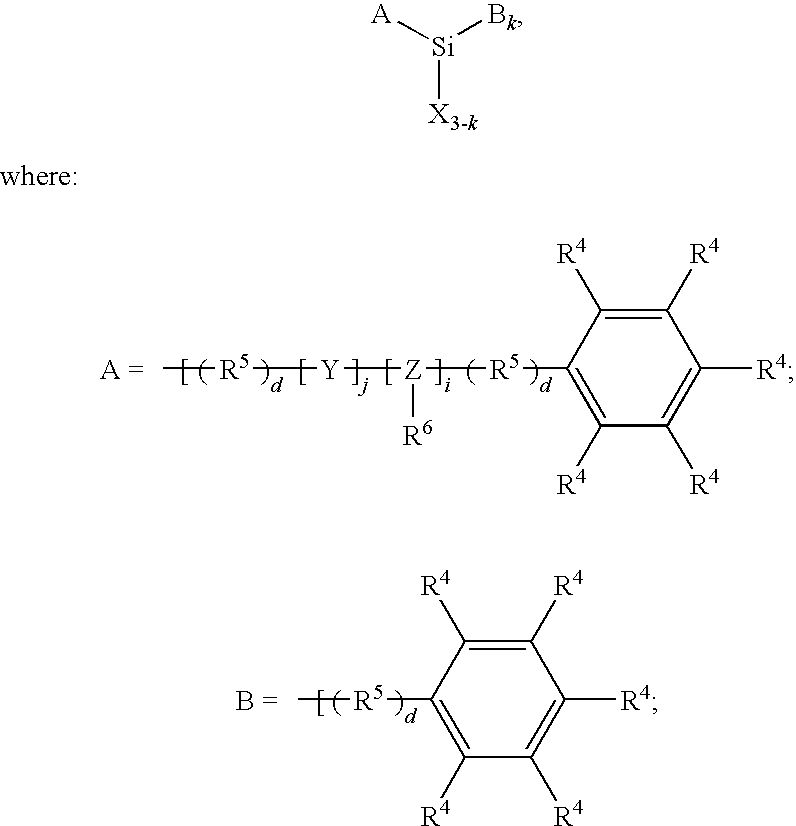

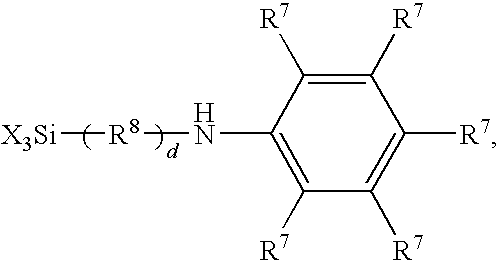

Negative photoresist for silicon koh etch without silicon nitride

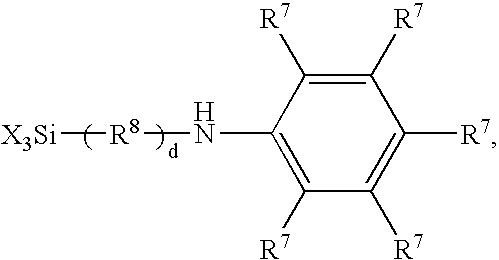

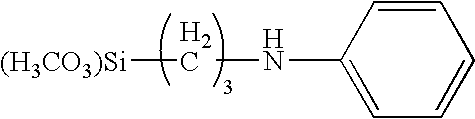

ActiveUS20070075309A1Eliminate needProtection formPhotosensitive materialsRadiation applicationsResistSilanes

New photoresists for use during the production of semiconductor and MEMS devices are provided. The primer layer preferably comprises a silane dissolved or dispersed in a solvent system. The photoresist layer includes copolymers prepared from styrene, acrylonitrile, and epoxy-containing monomers. The photoresist layer comprises a photoacid generator, and is preferably negative-acting.

Owner:BREWER SCI

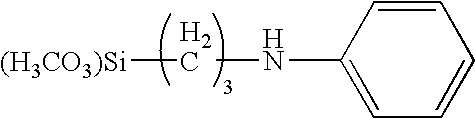

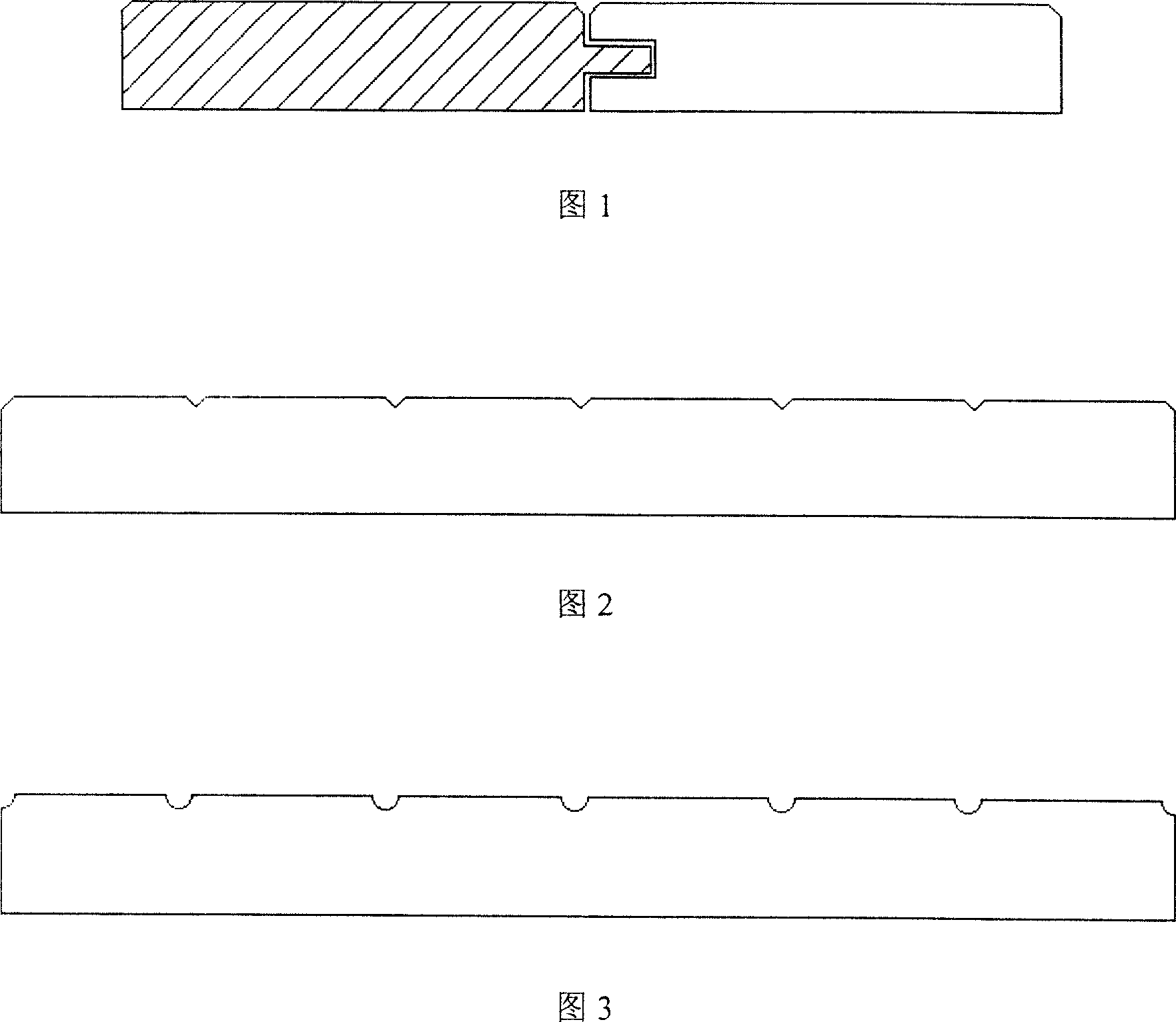

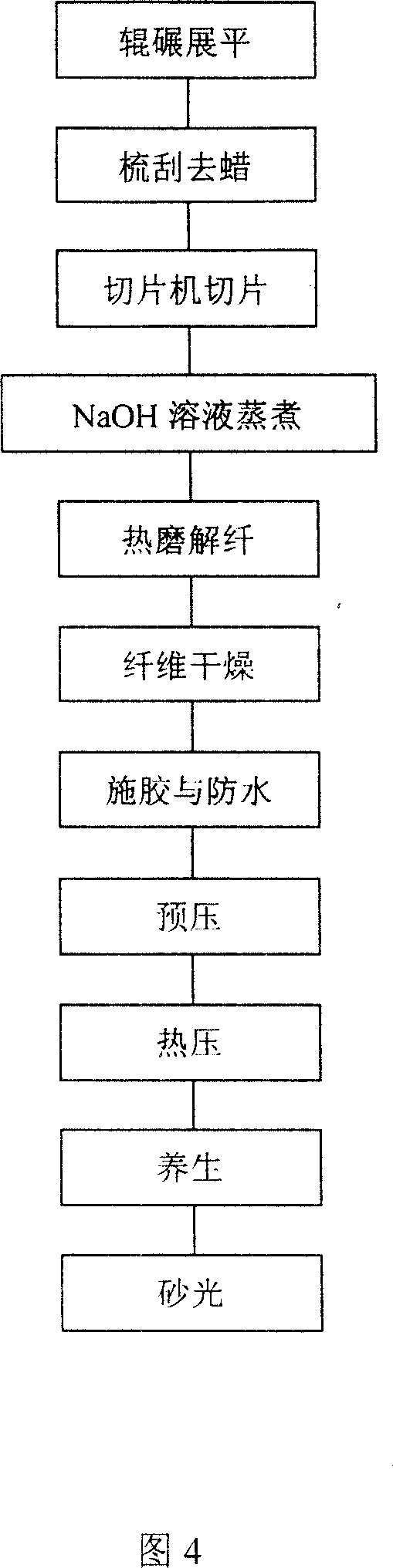

Medium density fiber board made from bamboo

InactiveCN1994702AIncrease profitImprove appearance qualityFibrous raw materialsDomestic articlesParaffin waxFiber

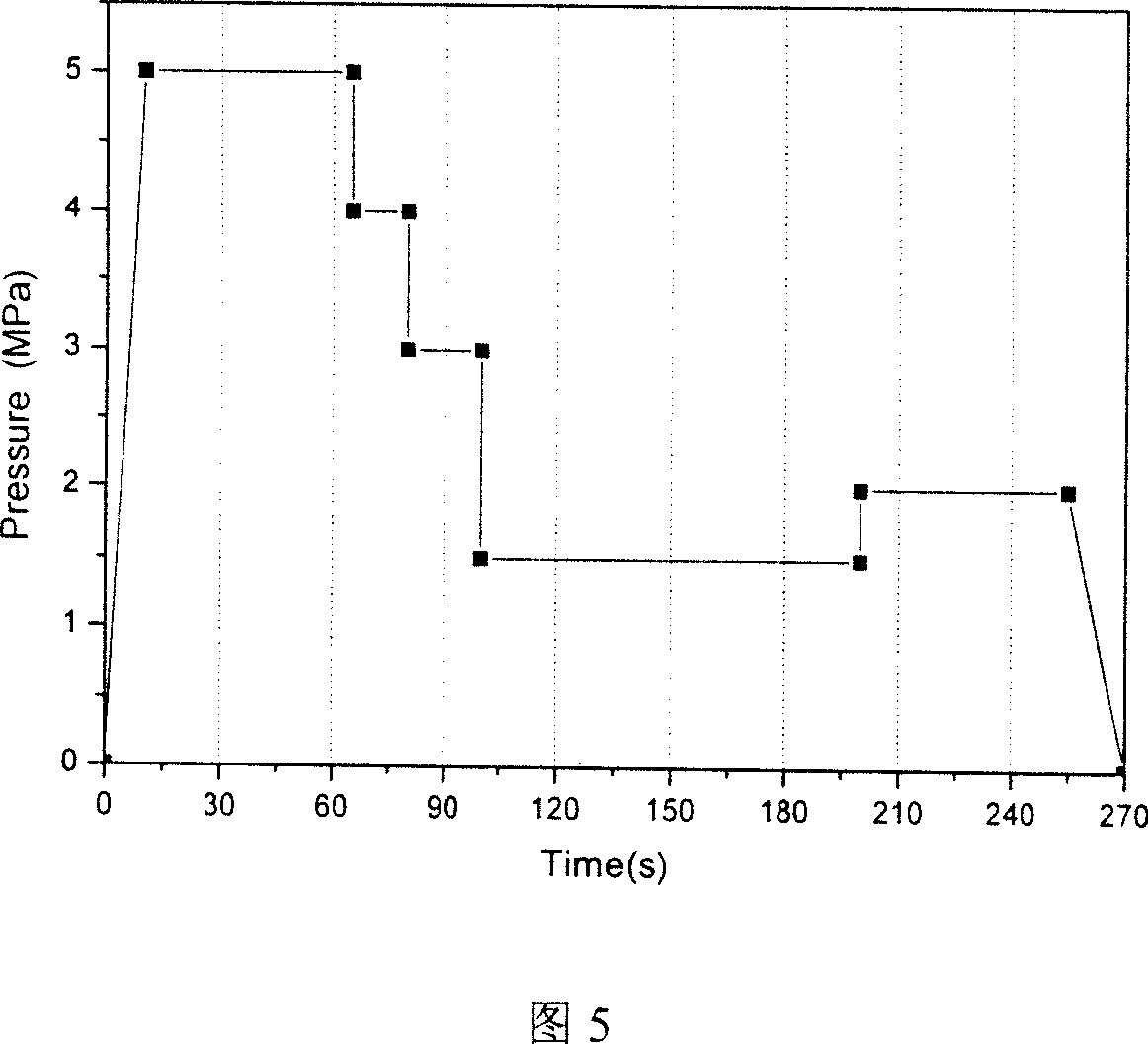

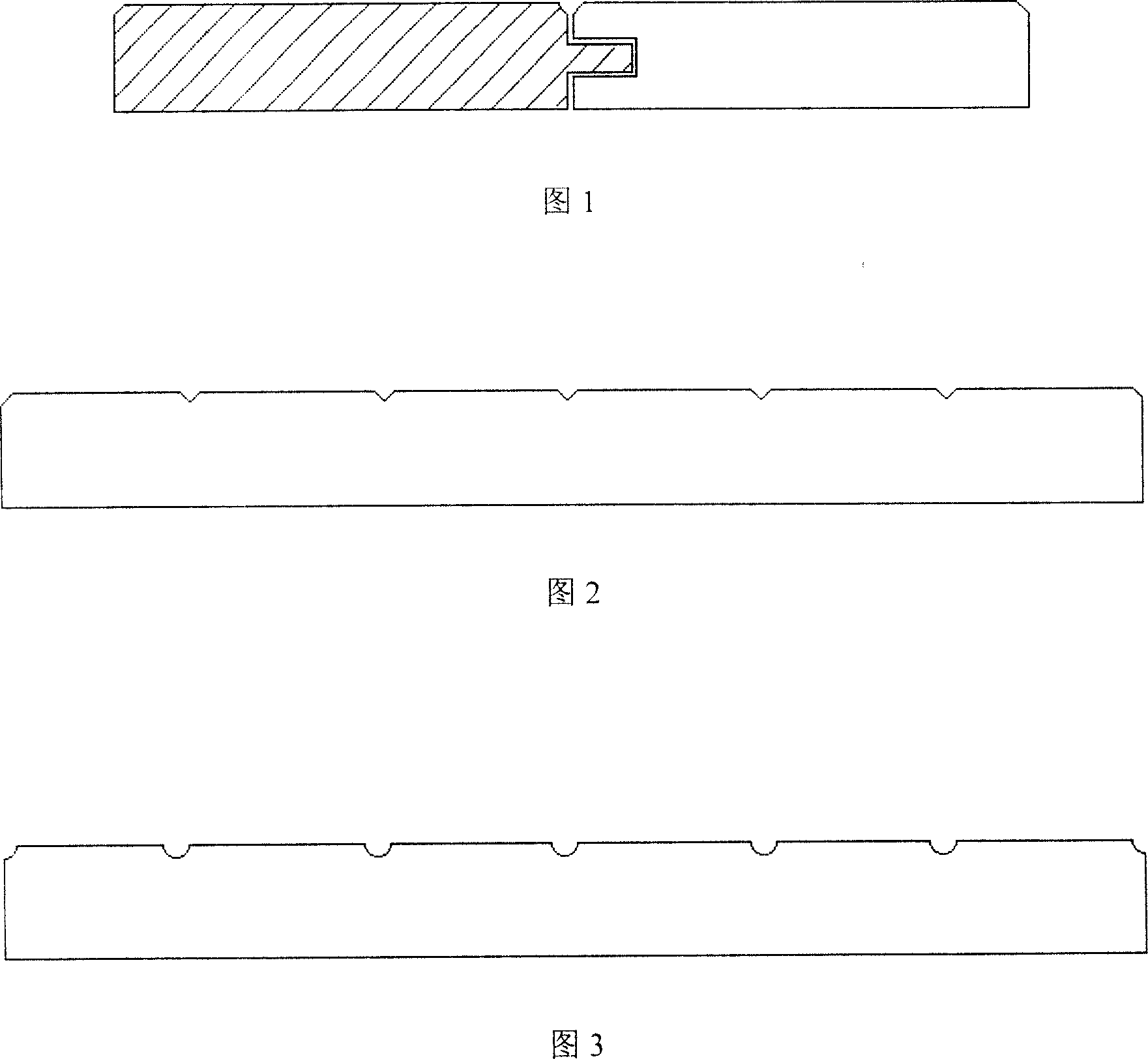

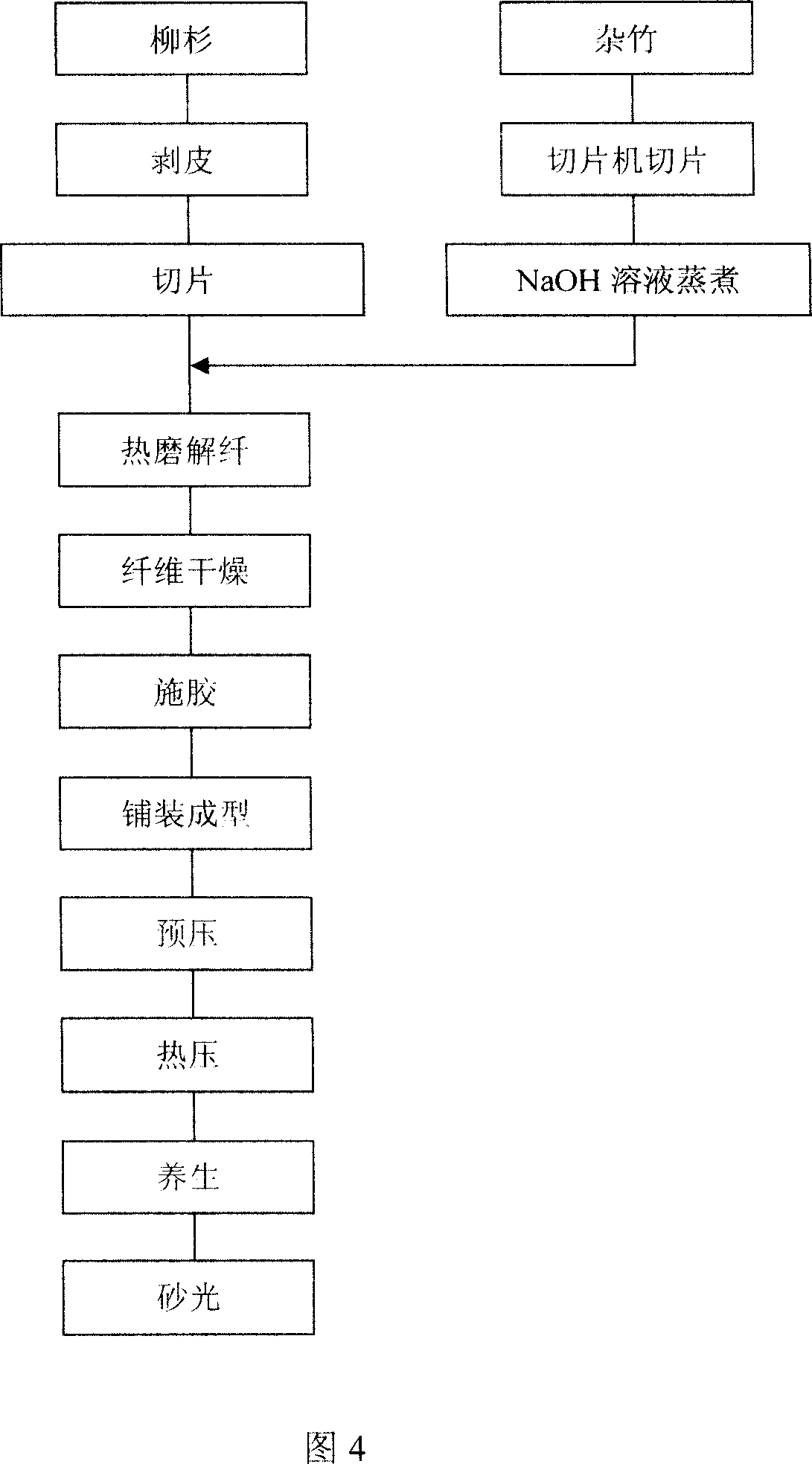

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 1-100 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

Medium density fiber board made from bamboo and wood

InactiveCN1994700AHigh yieldImprove mechanical propertiesFibrous raw materialsFlat articlesFiberParaffin wax

The invention relates to a bamboo middle-density fiber plate, made from bamboo and Japanese cedar, wherein it is formed by 50-95 Japanese cedar sheets, 5-50 bamboo sheets, 8-15 urea-formaldehyde glue, 0.5-5 anti-fungus agent, 0.2-3 solidifier, and 1-3 ceresin wax. And its preparation comprises that: putting bamboo sheets into solution while NaOH is 1-5% of bamboo weight; at 80-130Deg. C and 0.5MPa pressure, boiling it for 10-15min, to be mixed with Japanese cedar sheets, to be grinded and dried; plating urea-formaldehyde glue added with anti-fungus agent, solidifier and wax emulsion on the fiber to be thermally compressed.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

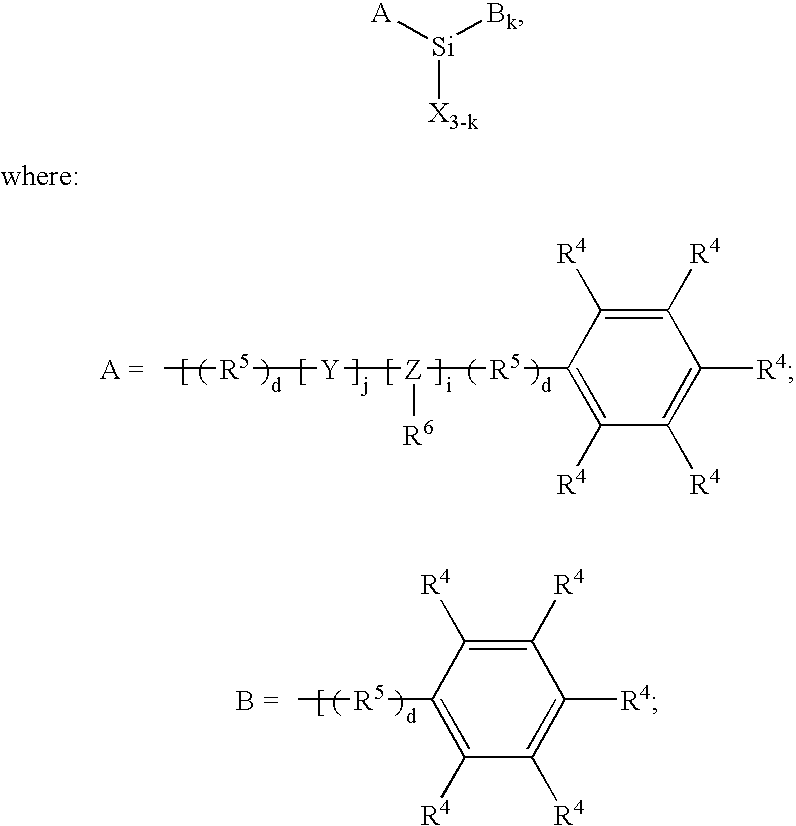

Alkaline-resistant negative photoresist for silicon wet-etch without silicon nitride

ActiveUS20080261145A1Eliminate needProtection formDiffusion transfer processesPhotosensitive materialsChemistryResist

New photoresists for use during the production of semiconductor and MEMS devices are provided. The primer layer preferably comprises a silane dissolved or dispersed in a solvent system. The photoresist layer includes a first polymer prepared from a styrene and an acrylonitrile, and a second polymer comprising epoxy-containing monomers (and preferably phenolic-containing monomers). The photoresist layer comprises a photoacid generator, and is preferably negative-acting.

Owner:BREWER SCI

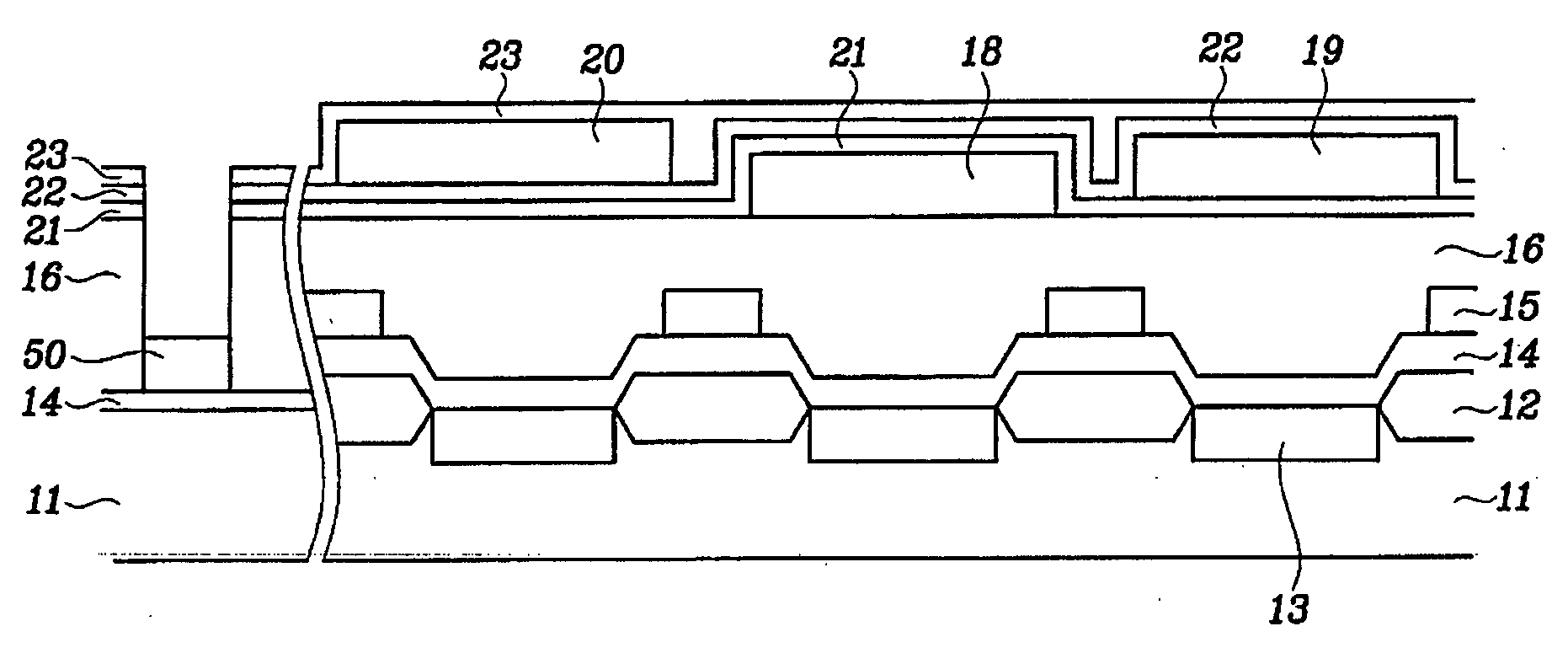

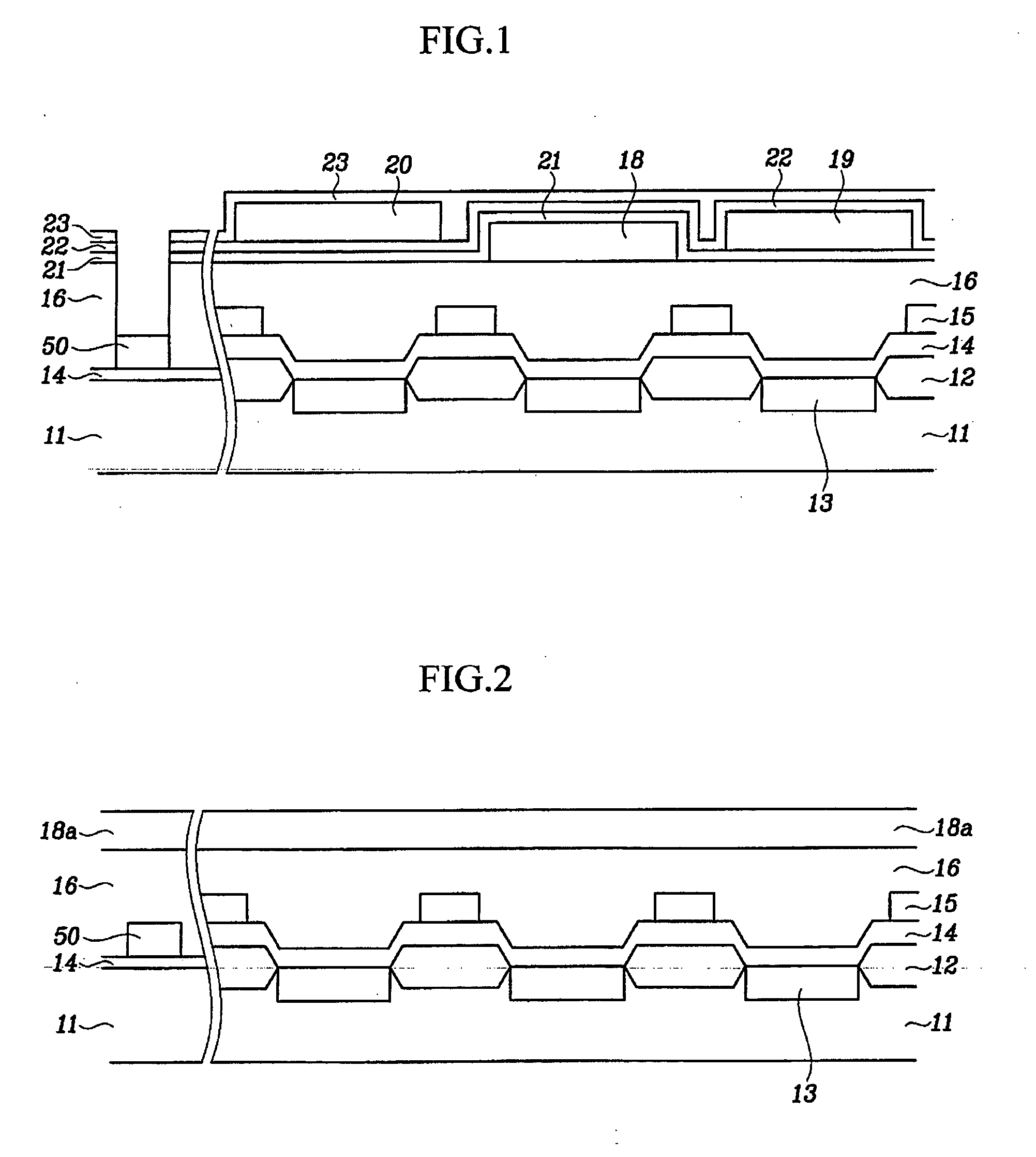

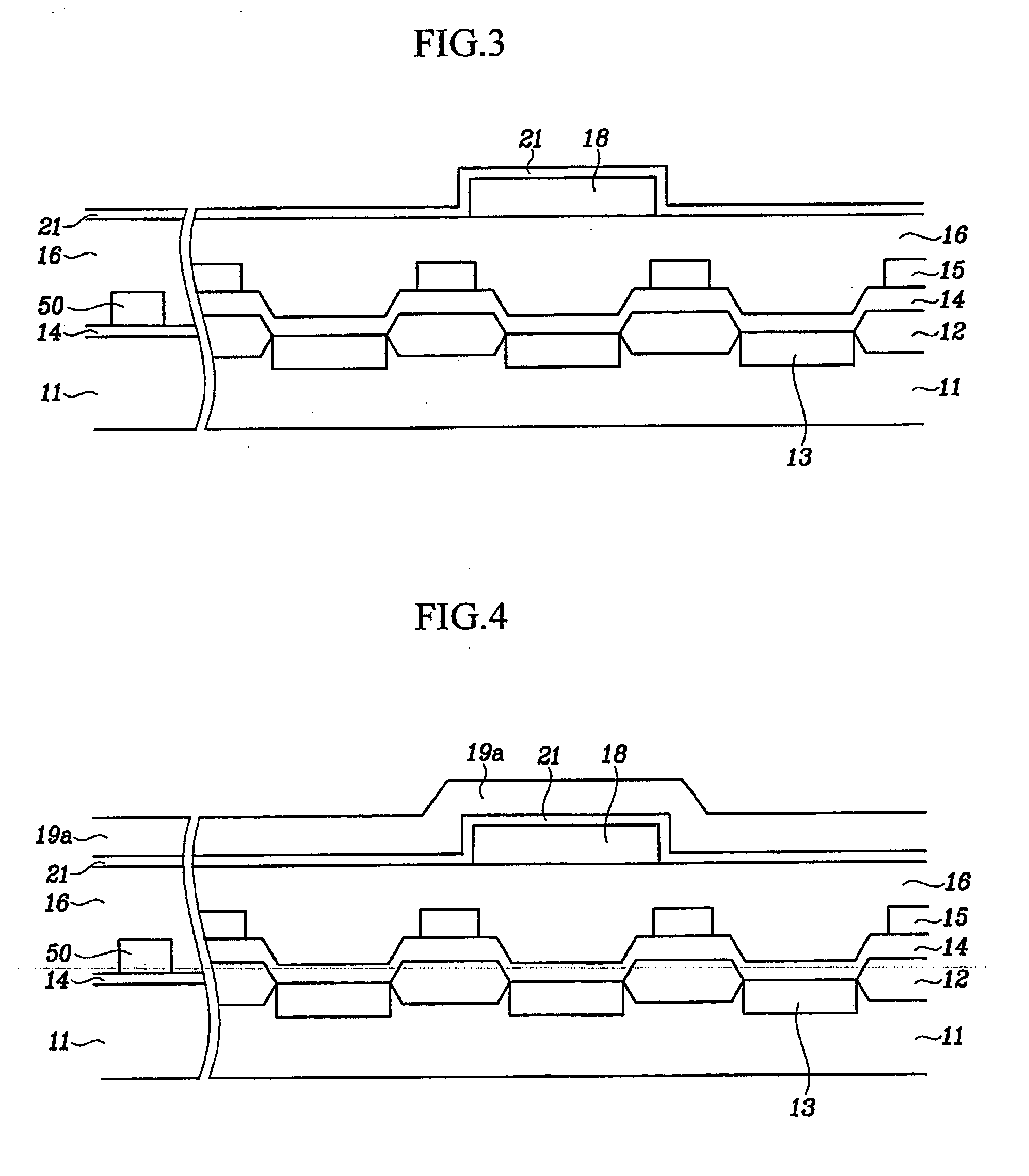

CMOS image sensor and manufacturing method thereof

InactiveUS20050082627A1Protection formAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingCMOSIsolation layer

A CMOS image sensor according to the present invention includes a substrate having a light receiving region, an interlayer insulating film formed on the substrate, a plurality of metal wirings formed on the interlayer insulating film so as to expose the light receiving region, a protection layer coated on the metal wirings and the interlayer insulating film, and a plurality of color filters formed on the protection layer, wherein at least one of the color filters is provided with an isolation layer formed on an upper surface thereof.

Owner:COLUMBA TECH INC

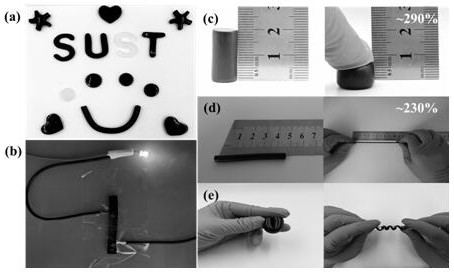

Biomimetic electronic skin medical stent material with self-repairing function and preparation method thereof

InactiveCN111825859AImprove adhesionPromote growthPharmaceutical delivery mechanismDomestic articlesPolystyreneBiocompatibility

The invention relates to the field of gelatin-based biomedical materials, in particular to a preparation method and application of a bionic electronic skin medical stent with a self-repairing function. The method is characterized in that gelatin extracted from an acellular fetal calfskin dermal matrix with good biological safety is used as a raw material; then, conducting polymer poly (3, 4-ethylenedioxythiophene) with good biocompatibility is used; compounding a polystyrene sulfonate (PEDOT: PSS) solution with self-made acidified carbon nanotubes (H-MWCNTs); the hydrogel stent with a multifunctional three-dimensional network space structure is obtained through crosslinking of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), and the hydrogel is good in biocompatibility and high in mechanical strength, has both self-repairing performance and tissue regeneration inducing repairing performance and can be widely applied to skin wound repairing treatment.

Owner:SHAANXI UNIV OF SCI & TECH

Essential element nutritive preparation for intestine

InactiveCN1824293APromote recoveryProtection formOrganic active ingredientsHeavy metal active ingredientsIntestinal structureMedicine

A nutritive medicine containing important intra-intestinal nutrients for treating acute pancreatitis and the dangerous patients is an improvement on existing one in such areas that using malt dextrin to decrease the ratio of carbohydrate, increasing the ratios of medium-chain fatty acids and non-saturated monofatty acid, and additionally using probotics and some rare elements.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

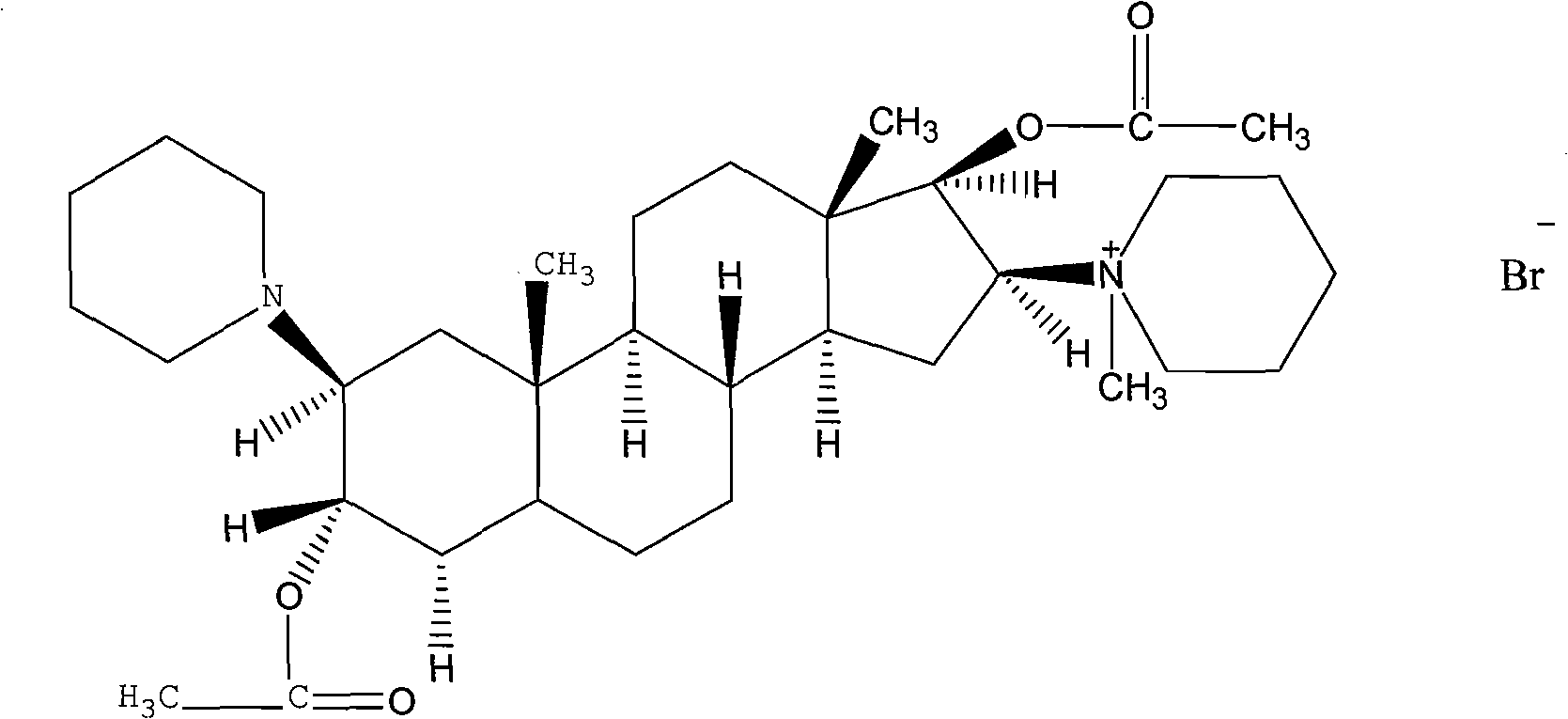

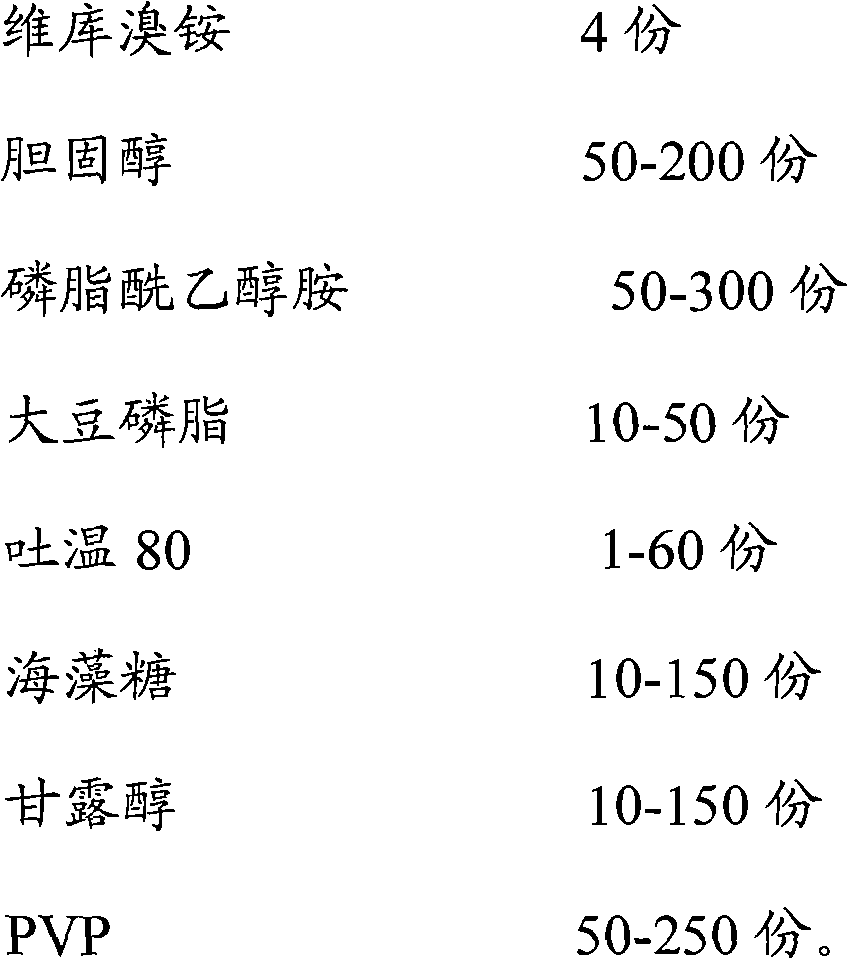

Vecuronium bromide liposome injection

InactiveCN102319215AImprove stabilityProtection formOrganic active ingredientsMuscular disorderSolubilitySide effect

The invention discloses a vecuronium bromide liposome injection and a preparation method thereof. The liposome injection is prepared from vecuronium bromide, cholesterol, phosphatidyl ethanolamine, soyabean lecithin, twain 80, trehalose, mannitol and polyvinylpyrrolidone in a specific weight ratio. The liposome injection has high preparation stability, and the liposome is not cracked due to fusion, ice crystals and the like in the refrigerating process and keeps high entrapment efficiency even after being stored for a long-time. Due to the adoption of the injection, the solubility of the vecuronium bromide is improved, the quality of a preparation product is improved, toxic and side effects are reduced, the retention time of a medicament is increased during systemic circulation, the bioavailability of the medicament is enhanced, the curative effect is improved remarkably; and moreover, the preparation method is simple and is suitable for industrial production.

Owner:HAINAN LINGKANG PHARMA CO LTD

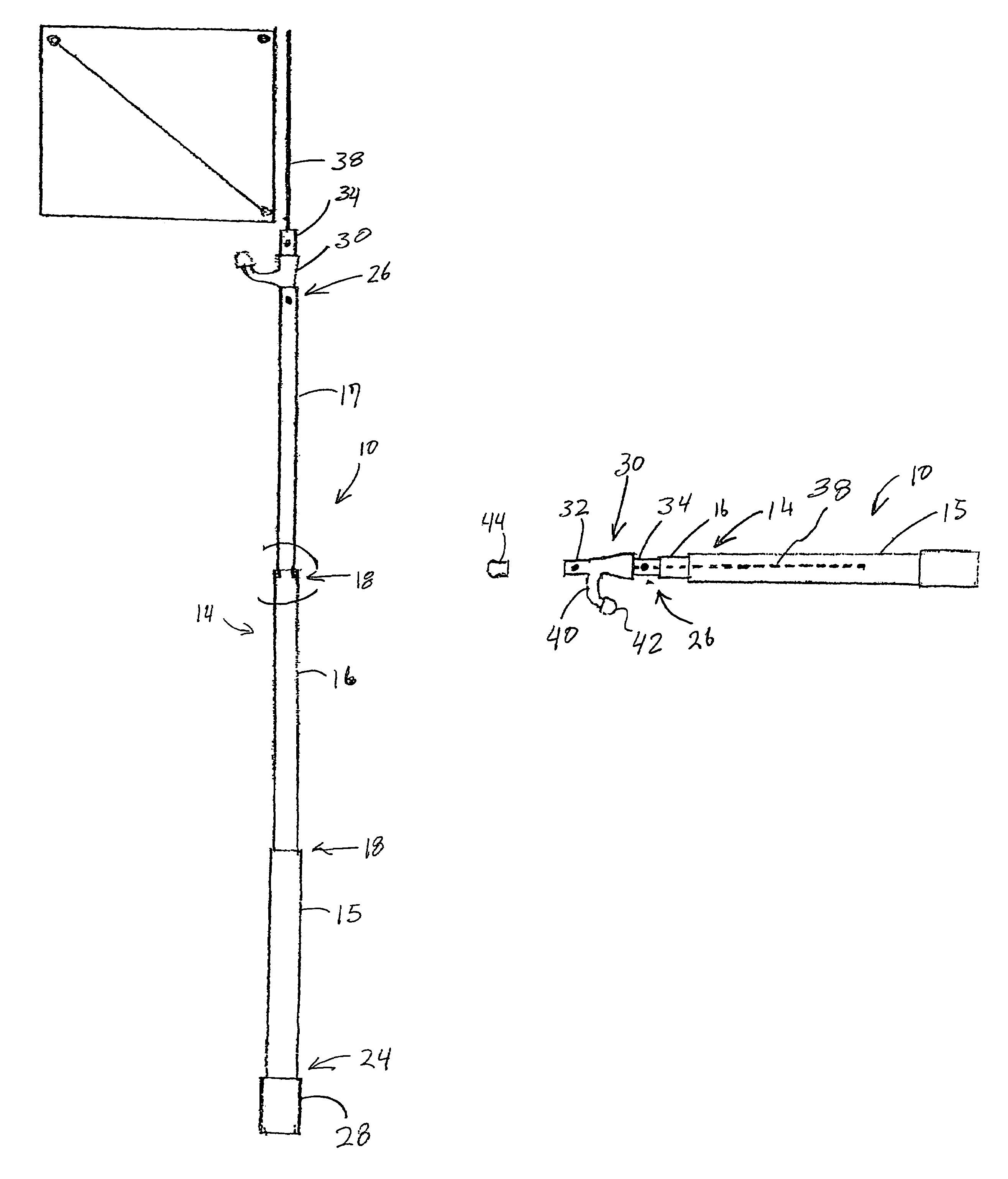

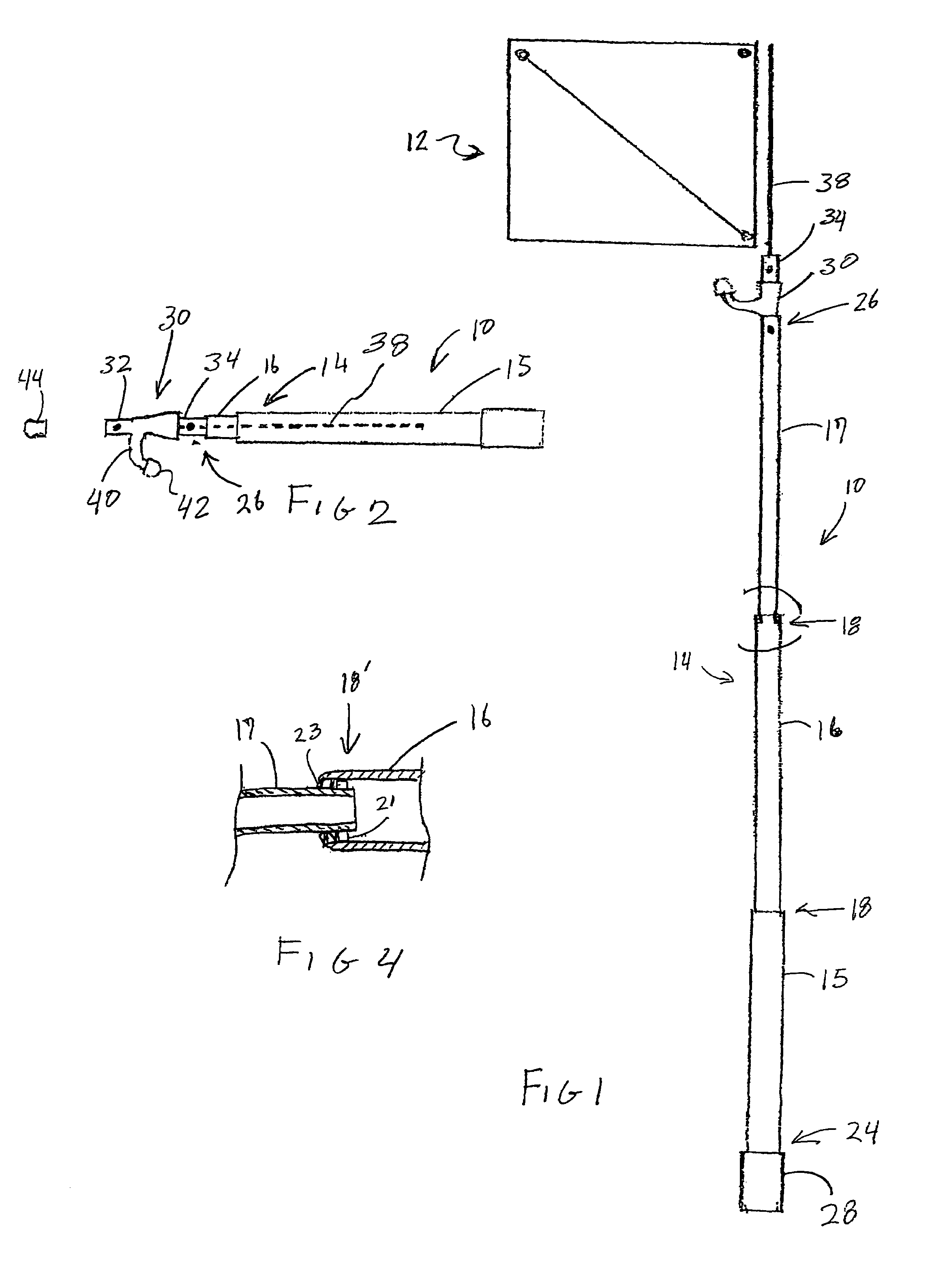

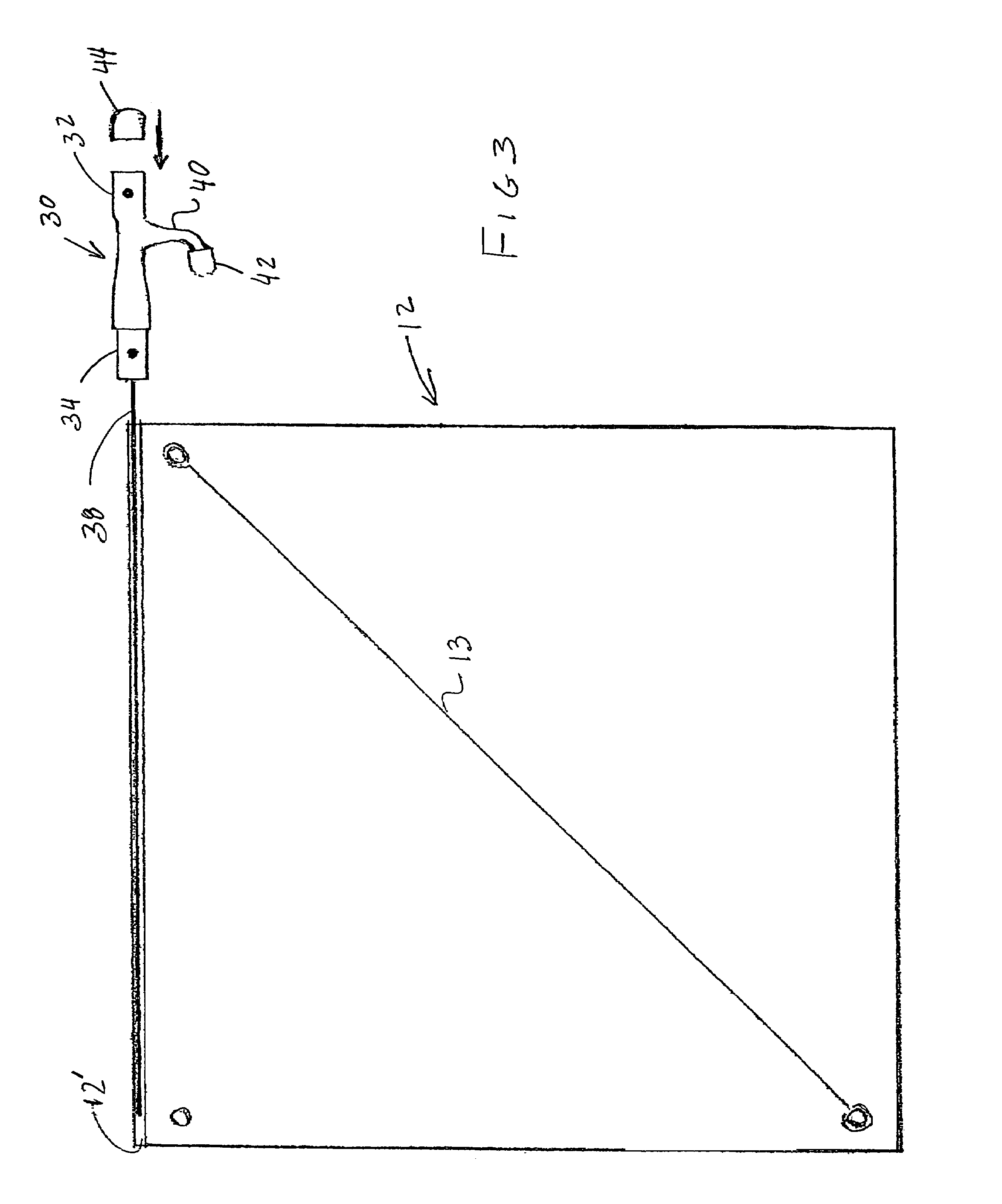

Signal support assembly

InactiveUS7299765B1Shorten the lengthProtection from damageBoat hooksFlags/bannersVariable lengthBiomedical engineering

A support assembly for a signal such as a signal flag or the like, which is structured for multiple uses by the provision of an end piece removably attached in different operative positions to the distal end of a staff having an elongated configuration of variable length. The multiple uses of the support assembly is due to the end piece comprising a tool, preferably in the form of a hook, such that when the end piece / tool is disposed in at least one of the operative orientations, the staff and end piece / tool can be used as a boat hook assembly. When so used, a shaft structured to support the signal flag thereon may be disposed on the interior of the staff, along with the flag furled thereabout. Another of the operative orientations comprises the flag shaft disposed exteriorly of the staff in an exposed position for display of the signal flag thereon.

Owner:PHELPS JAMES

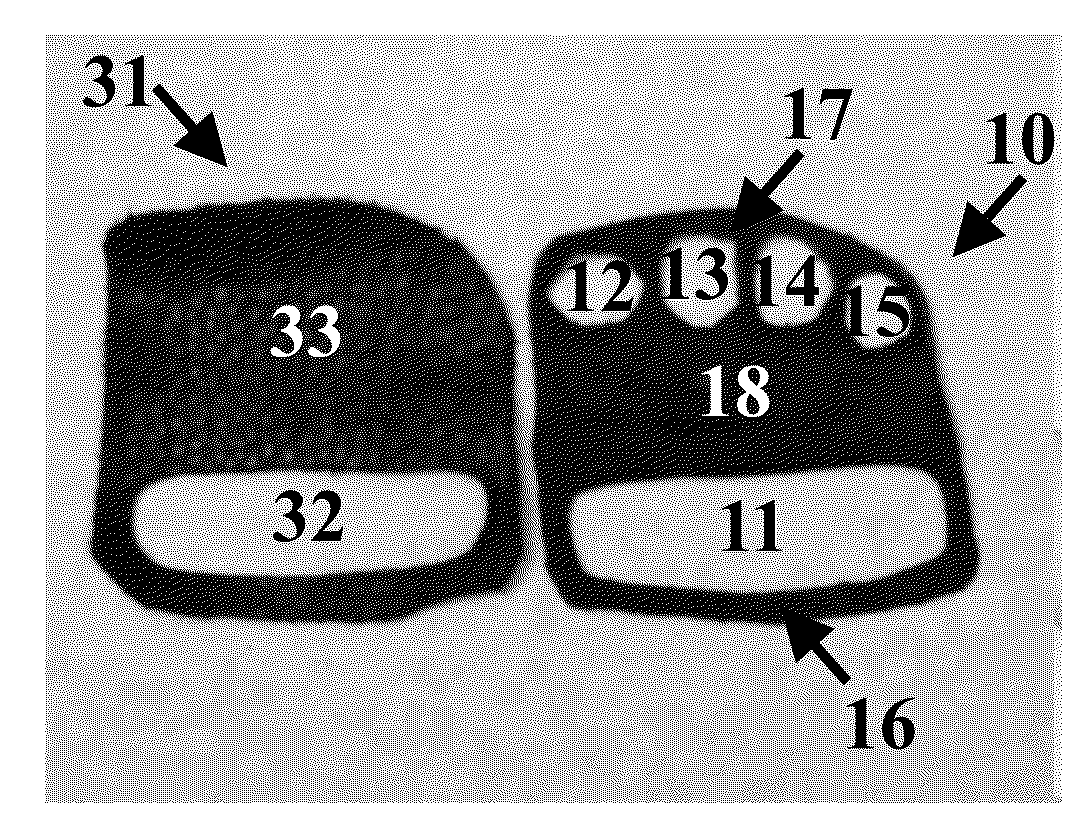

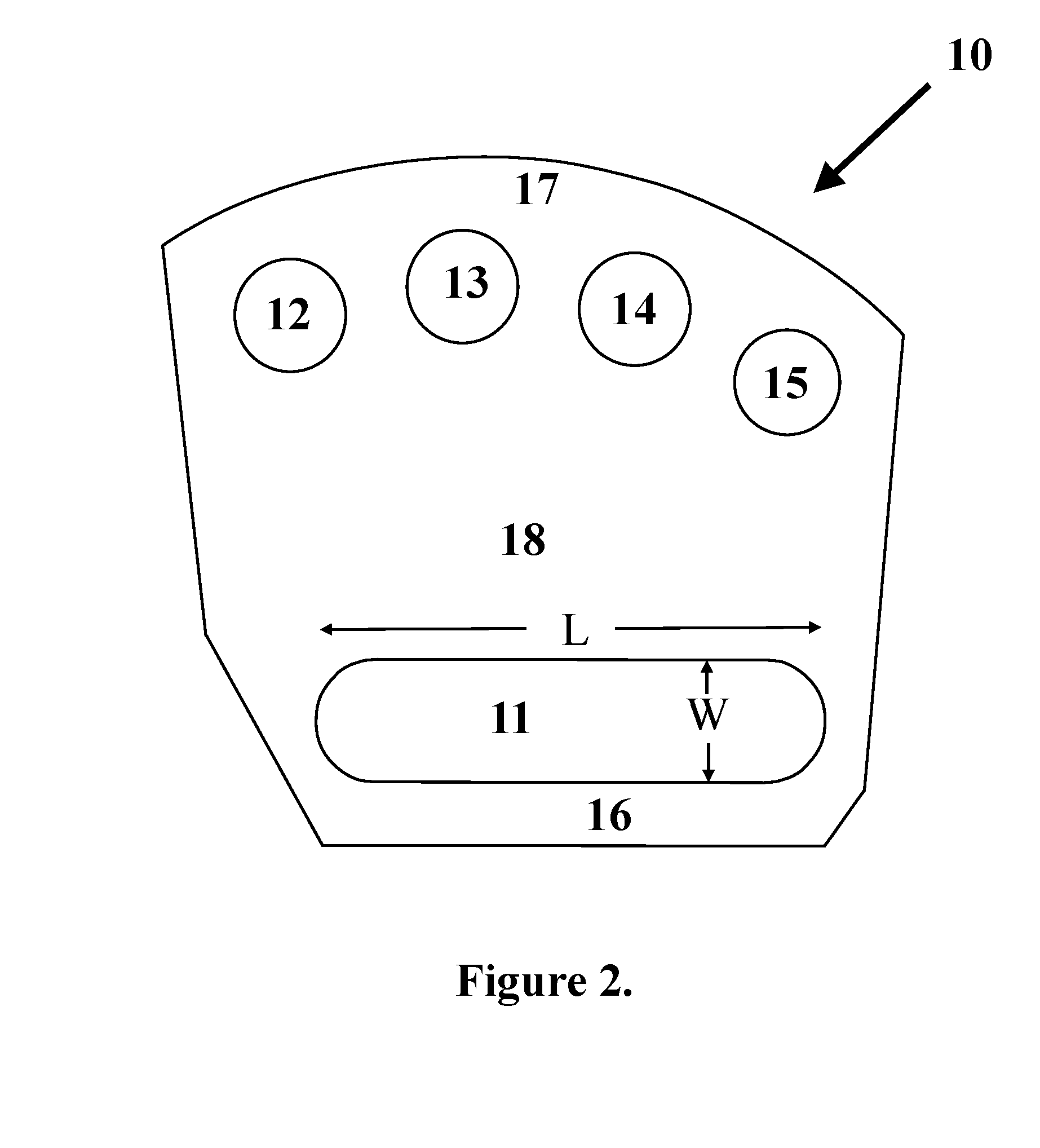

Hand Pad

InactiveUS20160250511A1Improve securityProtection formDumb-bellsProtective garmentElectrical and Electronics engineeringHand palms

Owner:NOLAN MATTHEW

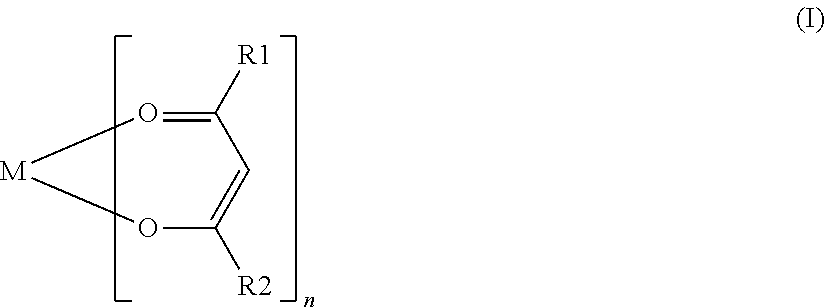

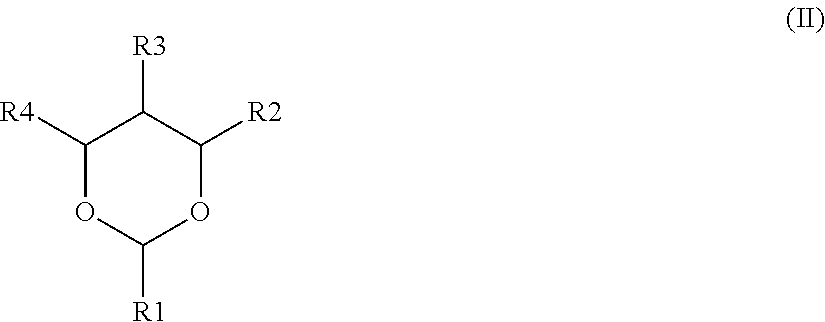

Nonaqueous secondary battery

InactiveUS20110183214A1Low costPromote resultsOrganic electrolyte cellsSecondary cellsCouplingAlkoxy group

A positive electrode active material has an average particle diameter of 4.5 to 15.5 μm and a specific surface area of 0.13 to 0.80 m2 / g. A positive electrode mixture layer contains at least one of a silane coupling agent and / or at least one of aluminum, titanium, or zirconium based coupling agent having an alkyl or an alkoxy groups having 1 to 18 carbon atoms at a content of 0.003% by mass or more and 5% by mass or less with respect to the mass of the positive electrode active material. The nonaqueous electrolyte contains a 1,3-dioxane derivative at a content of 0.05% by mass or more with respect to the total mass of the nonaqueous electrolyte. Thus a nonaqueous secondary battery that has good high-temperature cycle characteristics and suppresses an increase in self-discharge after repetition of charge and discharge cycles at high temperature is provided.

Owner:SANYO ELECTRIC CO LTD

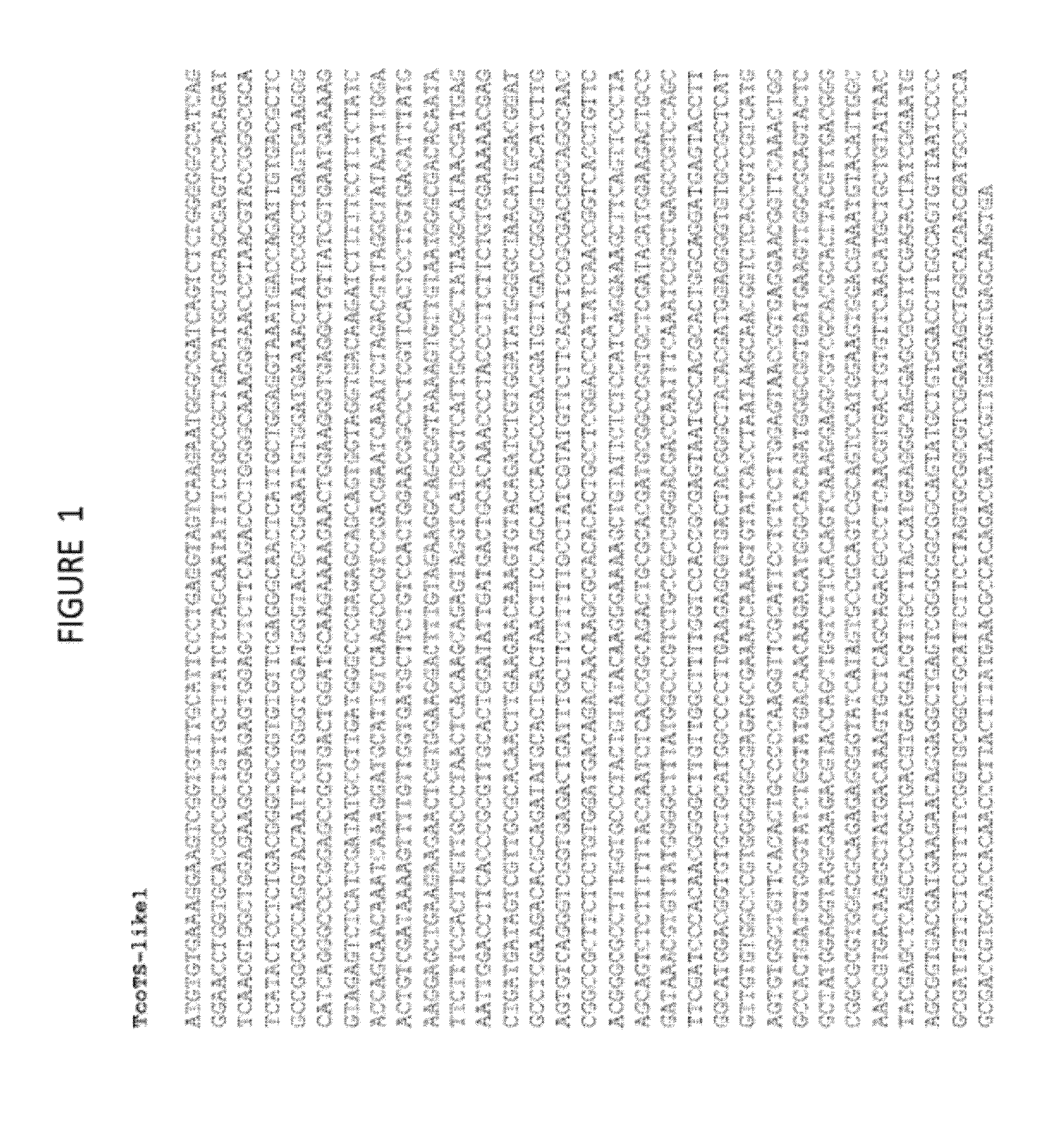

Anti-trypanosomiasis vaccines and diagnostics

The present invention has as an object a novel genetic material coding for trans-sialidase-like proteins of African trypanosomes, and relates to the use of said genes and proteins in vaccines, therapeutics and diagnostics. The present invention also relates to the immunization of human and / or nonhuman animals against trypanosomosis.

Owner:UNIV BORDEAUX SEGALEN +1

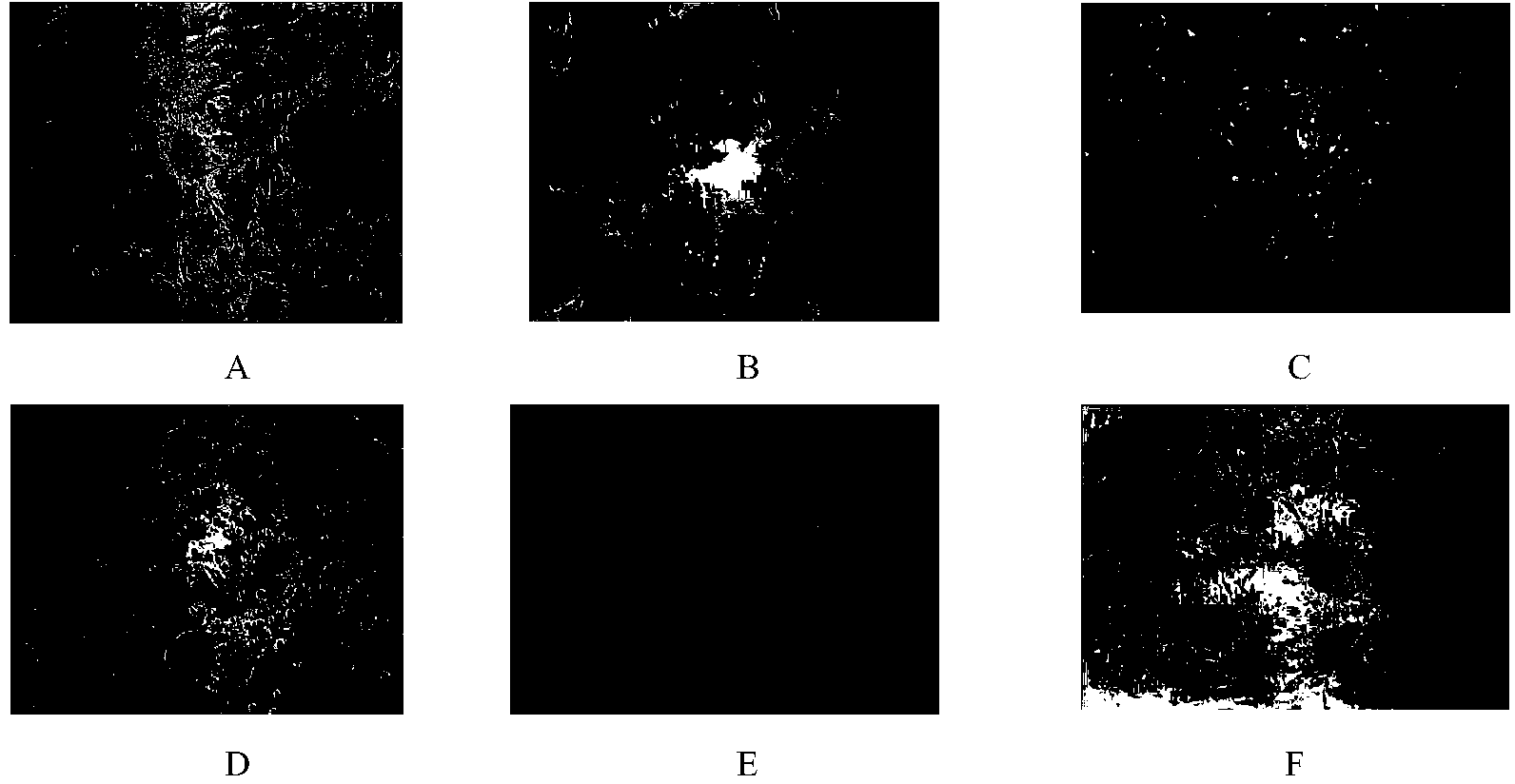

Application of morindae officinalis oligosaccharide pentasaccharide to preparation of drug for treating myocardial ischemia and reperfusion injury

InactiveCN103638034AImprove protectionProtection formOrganic active ingredientsSugar derivativesReperfusion injuryIrritation

The invention discloses an application of a morindae officinalis extract and morindae officinalis oligosaccharide pentasaccharide to preparation of a drug for treating myocardial ischemia and / or reperfusion injury and promoting therapeutic angiogenesis. The myocardial ischemia and reperfusion injury belong to secondary injury brought to an organism when the hemoperfusion of myocardium is stopped or poor, i.e., after the myocardium is subjected to ischemia, hypoxia injury, circulation reinstitution and blood supply recovery. The morindae officinalis extract and the morindae officinalis oligosaccharide pentasaccharide both play a role in protecting an in-vivo rat myocardial ischemia reperfusion injury model and an in-vitro purification cultured neonatal rat myocardial cell hypoxia / reoxygenation injury model, and can be used for remarkably reducing the myocardial infarction area and the incidence rate of reperfusion arrhythmias, effectively protecting the form of a myocardial cell and relieving the injury of hypoxia / reoxygenation to the myocardial cell. The therapeutic angiogenesis promotion means that the aims of recovering the blood supply of ischemic myocardium and improving the heart function are achieved through increasing the functional coronary artery branch or side branch under the irritation actions of some methods, including the therapeutic actions of some drugs.

Owner:冯国清 +1

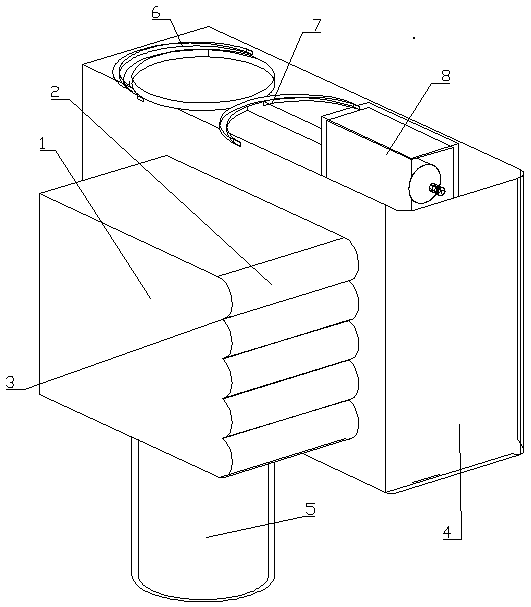

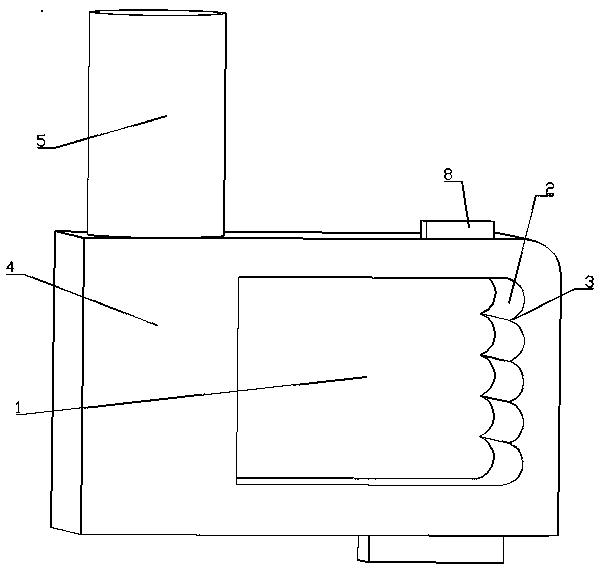

Neurosurgical ultrasonic focusing assisted three-stage atomization cooling and postoperative wound film forming device

ActiveUS20200254282A1Reduce bone grinding temperatureGuaranteed cooling effectHead bandagesUltrasound therapyNeurosurgeryNanofluid

A neurosurgical ultrasonic focusing assisted three-stage atomization cooling and postoperative wound film forming device has a transducer housing and a nozzle, wherein a horn is arranged in the transducer housing, at least two layers of piezoelectric ceramic sheets are arranged at the top of the horn, an electrode sheet connected with an ultrasonic generator is arranged between two adjacent layers of piezoelectric ceramic sheets, the bottom of the transducer housing is of a hemispherical structure, and a plurality of piezoelectric elements connected with the ultrasonic generator are arranged inside the hemispherical structure; and the nozzle is arranged at the bottom of the horn and connected with a medical nanofluid storage cup, compressed gas can also be introduced into the nozzle, and an electrode is also arranged inside the nozzle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Aortic valve stents to prevent paravalvular leaks

ActiveCN103705315BImprove complianceExcellent shape memory performanceHeart valvesProsthetic valveNatural state

The invention discloses an aortic valve stent (100) capable of preventing perivalvular leakage. The aortic valve stent (100) capable of preventing perivalvular leakage comprises a stent (110) and an artificial valve (104), wherein the stent (110) is composed of a plurality of grid cells (112); the artificial valve (104) is connected to the grid cells (112); a sealing unit (106) is arranged at the bottom of the stent (110); the sealing unit (106) is made from a metal memory material and laminated; in a natural state, the sealing unit (106) is arched outwards along the axial direction of the stent and of an annular structure along the peripheral direction of the stent (110); one end of the sealing unit (106) is free and is a free end (116); the other end of the sealing unit (106) is fixed with the bottom of the stent (110) by a fixing element, and is a fixed end (126); when the sealing unit (106) is compressed to enter a sheathing canal, the free end (116) of the sealing unit (106) turns towards the bottom end of the stent and around the fixed end (126), thus the sealing unit (106) is not superposed with the stent (110).

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

Application of Morindae officinalis oligosaccharide 6 glycan in preparation of myocardial ischemia and reperfusion injury resistance medicines

ActiveCN103665180AImprove protectionProtection formOrganic active ingredientsSugar derivativesReperfusion injuryOfficinalis

The invention discloses an application of a Morindae officinalis extract product and Morindae officinalis oligosaccharide 6 glycan in the preparation of medicines for resisting myocardial ischemia and / or reperfusion injury and promoting therapeutic angiogenesis. The myocardial ischemia and reperfusion injury are body injuries caused by the afresh circulation establishment and the blood supply recovery during the stopping or abnormality of the myocardial blood perfusion, like ischemic and anoxic injuries. The Morindae officinalis oligosaccharide 6 glycan has a protect effect on an in-vivo rat myocardial ischemia reperfusion injury model and an in-vitro purify-cultured mouse myocardial cell reoxygenation injury model, can substantially reduces the myocardial infarction area, can mitigate the reperfusion arrhythmia, can effectively protect the form of myocardial cells, and can mitigate the injuries of anoxic reoxygenation to the myocardial cells. The therapeutic angiogenesis promotion is characterized in that the ischemic myocardial blood supply recovery and the cardiac function improvement are realized by increasing the functional coronary arterial tree or coronary collateral through some irradiations comprising the treatment effects of some medicines.

Owner:ZHENGZHOU UNIV

Bone marrow specimen processing method, decalcification solution, and applications

InactiveCN109425523AEasy to sliceSmooth slicePreparing sample for investigationClear cellDistilled water

The invention provides a bone marrow specimen processing method, a decalcification solution, and applications. The bone marrow specimen processing method comprises following processing steps of bone marrow tissues: fixing and primary decalcification, dehydration, paraffin embedding, rough trimming, secondary decalcification, and slicing; the decalcification solution at least comprises formic acid,formaldehyde, and distilled water at a volume ratio of 198-202:48-52:190-210, wherein the mass concentration of formic acid ranges from 97 to 99%. The bone marrow specimen processing method is used for processing bone marrow specimen, so that slices with relatively complete tissue structures and clear cell structures can be obtained, and it is beneficial for observation of slices under microscopes.

Owner:SHANGHAI SIMPLEGENE CLINICAL LAB CO LTD

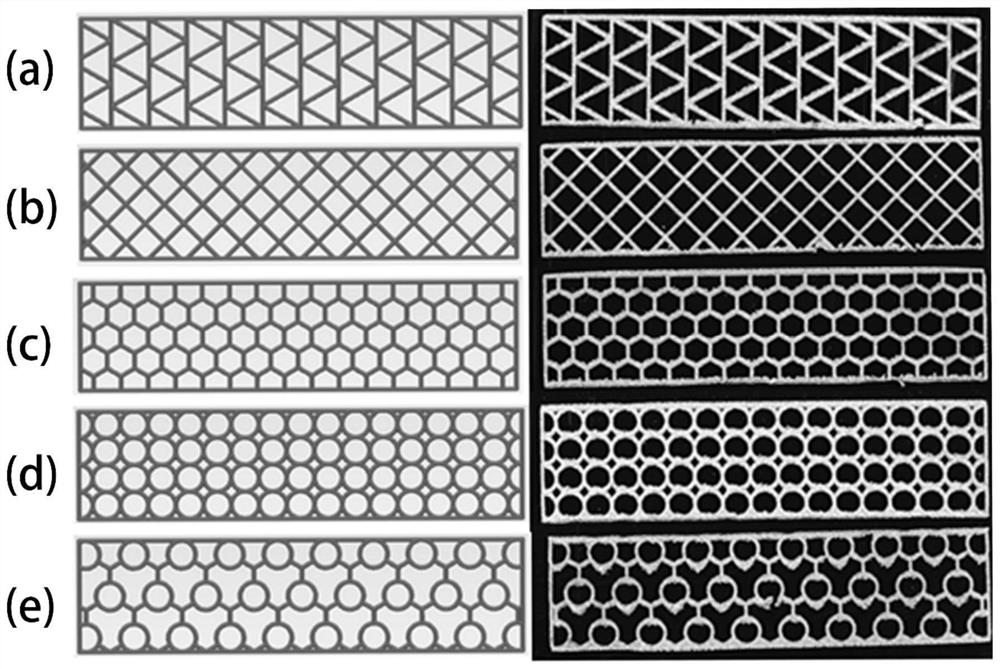

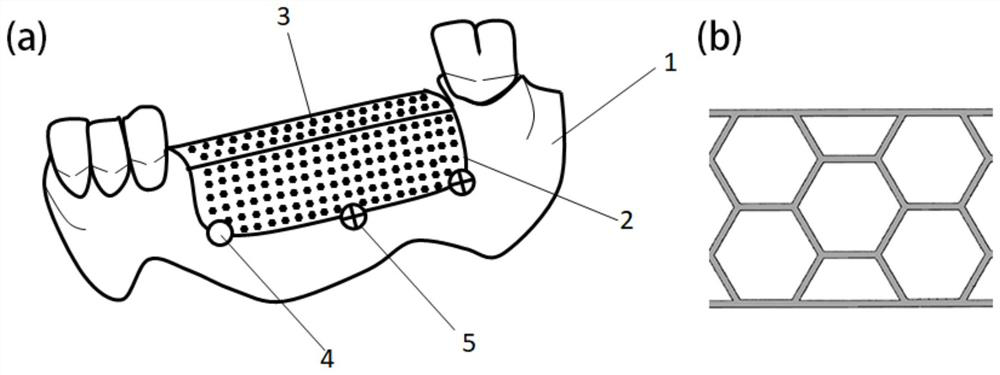

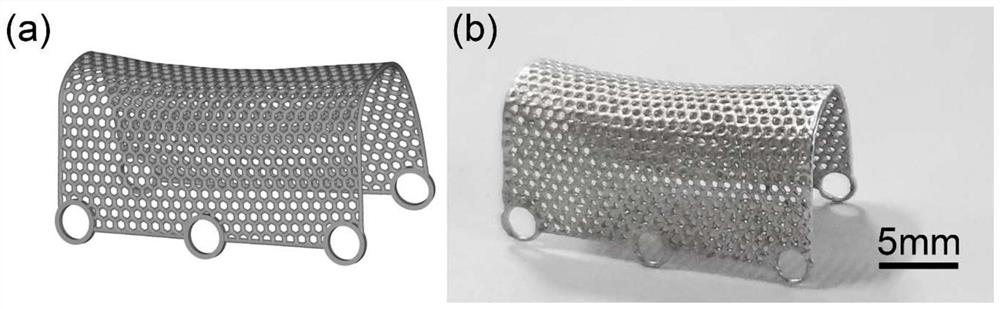

Degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction

PendingCN114099079APrecise positioningProtection formAdditive manufacturing apparatusJoint implantsEngineeringDentistry

The invention discloses a degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction. According to the magnesium mesh, a personalized model structure is designed according to CT data, high-precision preparation of the magnesium mesh is achieved through the 3D printing technology, and the magnesium mesh is made to be tightly attached to the anatomical appearance of the alveolar bone; the defects that a traditional titanium mesh needs to be bent in an operation and the postoperative exposure rate is high are overcome, the operation difficulty and time are reduced, and the operation success rate is increased. The surface of the magnesium mesh is of a completely-perforated regular hexagon structure, and the mesh structure has the advantages of self-supporting, easiness in forming, high printing precision, good mechanical property and the like. Meanwhile, by combining the degradability of a magnesium material and the advantage of promoting osteogenesis through bone induction of magnesium ions, the problems that a titanium mesh shields stress and cannot be degraded, and secondary operation is needed for taking out the titanium mesh during tooth implantation are solved. The preparation process is simple, the preparation period is short, raw material loss is small, repeatability is high, pollution is avoided, and the prepared magnesium mesh has the advantages of being controllable in appearance and high in precision and can serve as a new generation of oral cavity alveolar bone large-area bone defect repairing support.

Owner:SHANGHAI JIAO TONG UNIV +1

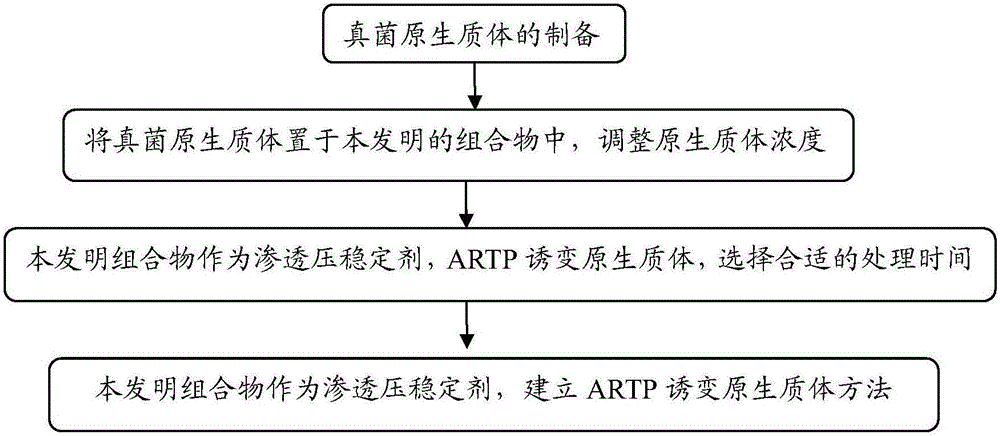

Osmotic pressure stabilizer and use thereof

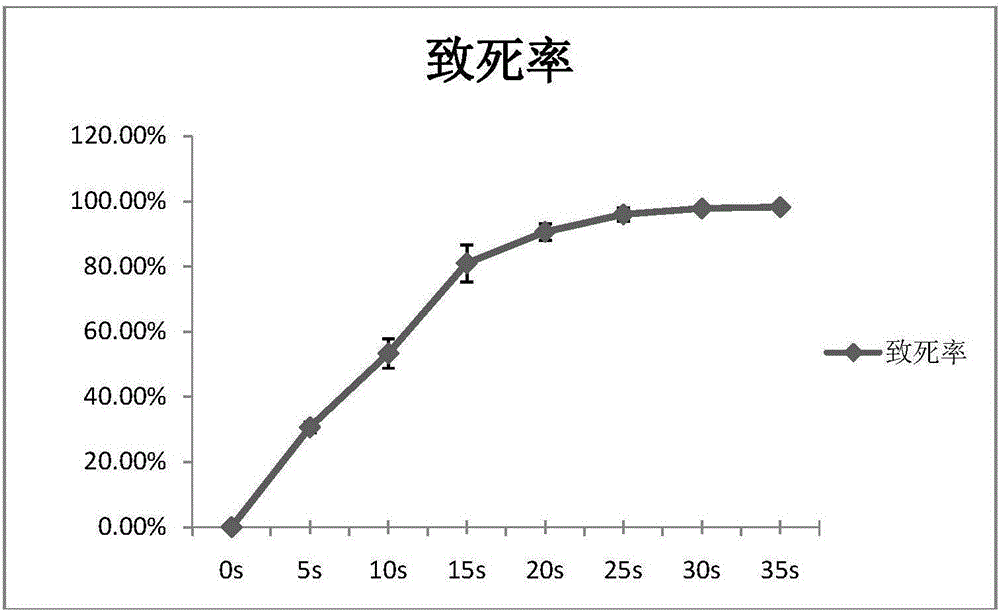

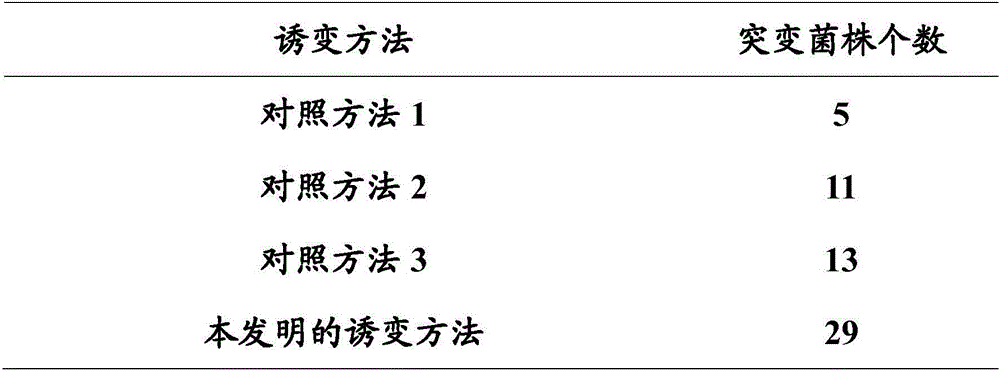

ActiveCN106754433AProtection formAvoid inactivationFungiElectrical/wave energy microorganism treatmentRoom temperatureProtoplast

The invention relates to a composition, which contains an osmotic pressure maintenance agent, a humectant and a pH buffer, wherein the pH value of the composition is 6.5 to 7.5. As an osmotic pressure stabilizer, the composition has a protection effect on a protoplast, and the protoplast can be prevented from being deactivated. When the osmotic pressure stabilizer composition is adopted, ARTP (atmospheric room temperature plasma) mutagenesis is performed on the protoplast, so that the mutation efficiency can be improved. The invention also relates to a method for mutagenizing the protoplast by virtue of the composition as the osmotic pressure stabilizer.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +2

Negative photoresist for silicon KOH etch without silicon nitride

ActiveUS7695890B2Eliminate needProtection formPhotosensitive materialsRadiation applicationsResistSilanes

New photoresists for use during the production of semiconductor and MEMS devices are provided. The primer layer preferably comprises a silane dissolved or dispersed in a solvent system. The photoresist layer includes copolymers prepared from styrene, acrylonitrile, and epoxy-containing monomers. The photoresist layer comprises a photoacid generator, and is preferably negative-acting.

Owner:BREWER SCI

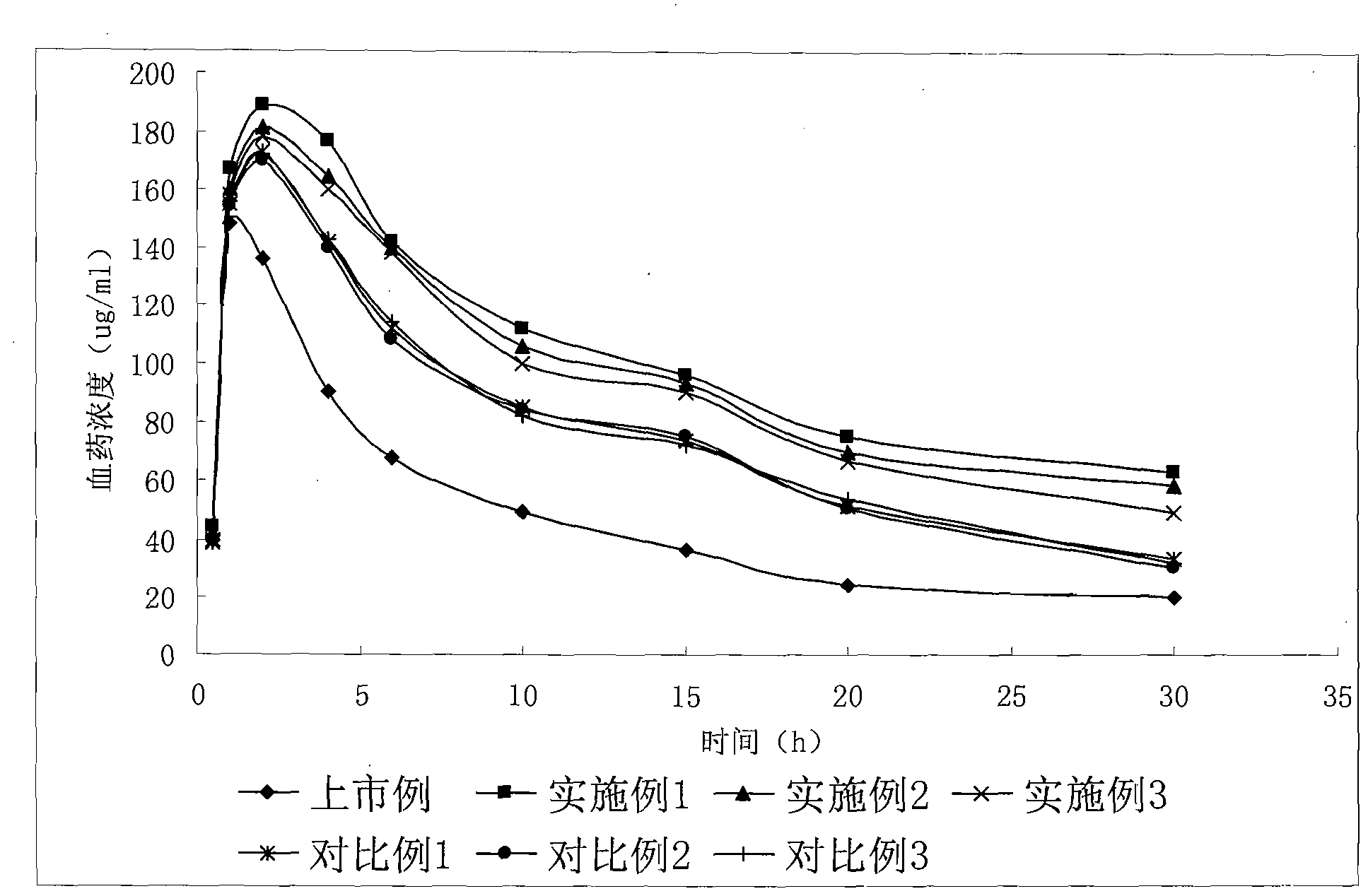

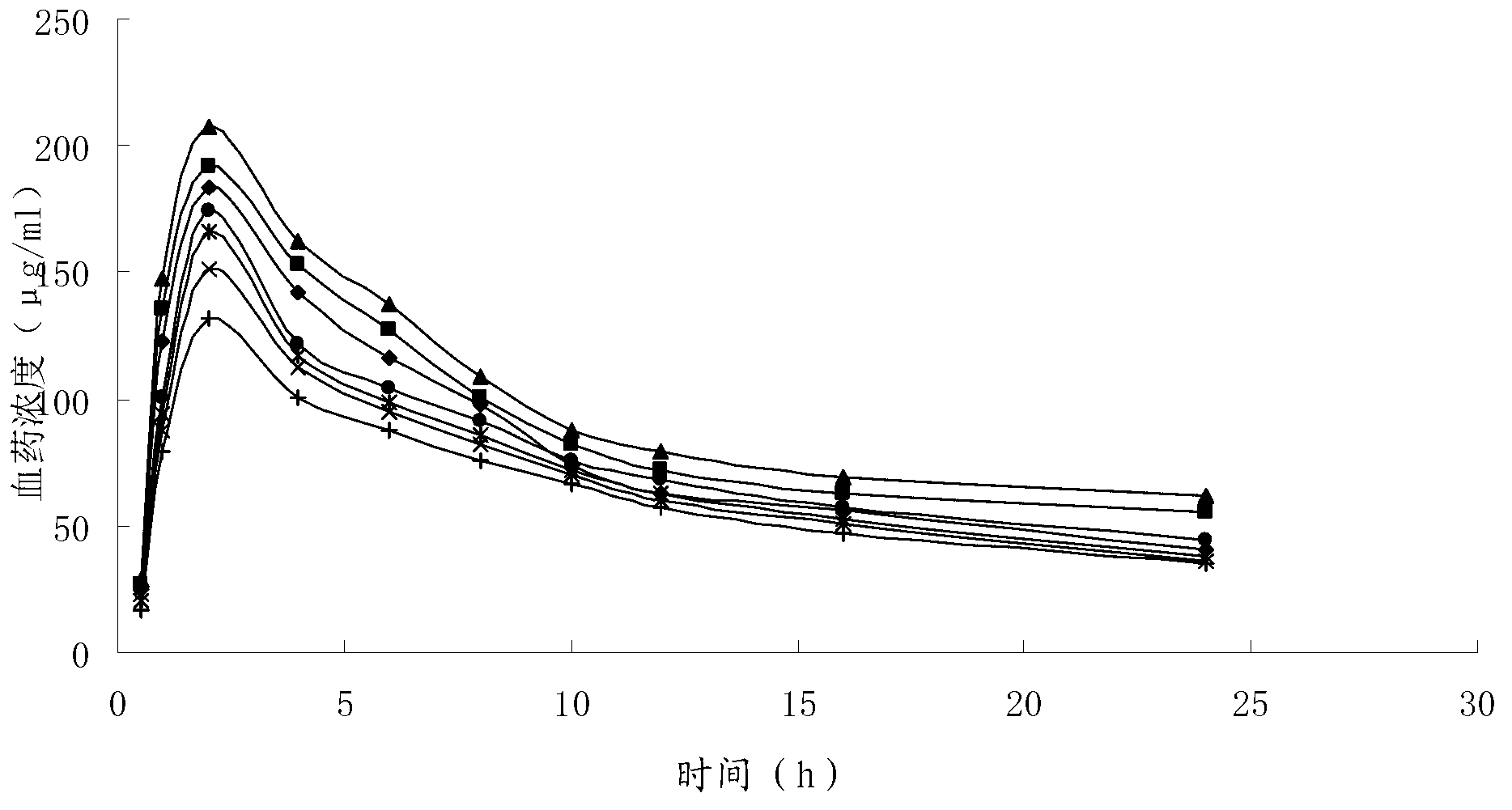

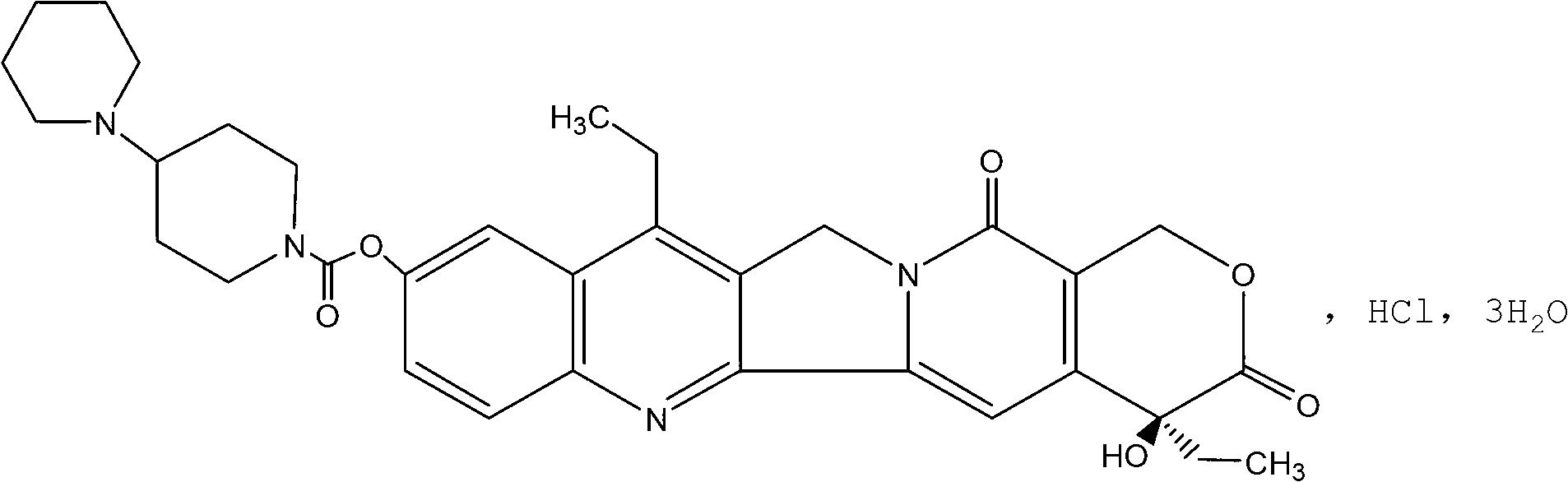

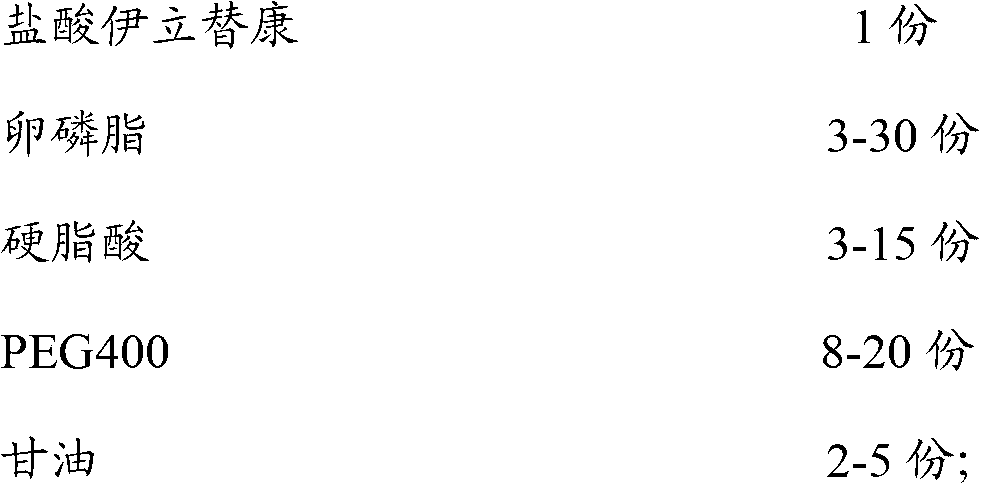

Irinotecan hydrochloride lipid nanoparticles injection

InactiveCN102697720AProtection formProtection stabilityOrganic active ingredientsPowder deliveryPolyethylene glycolOrganosolv

The invention discloses an irinotecan hydrochloride lipid nanoparticles injection and a preparation method thereof. Mixed phase is formed by dissolving irinotecan hydrochloride and stearic acid in organic solvent and dissolving lecithin in buffer salt solution; aqueous solution of PEG (polyethylene glycol) 400, glycerol and trehalose is adopted as aqueous phase; and then irinotecan hydrochloride is loaded in lipid nanoparticles by combining stirring emulsification and high-pressure emulsion homogenizing to obtain the irinotecan hydrochloride lipid nanoparticles injection. The inventive lipid nanoparticles preparation has the advantages of high drug loading rate, uniform particle size, long drug retention time in blood circulation, better sustained-release and controlled-release effect, simple preparation method and device, easy operation, improved product quality, reduced toxic and side effects, and suitability for industrialized production.

Owner:灵康药业集团股份有限公司

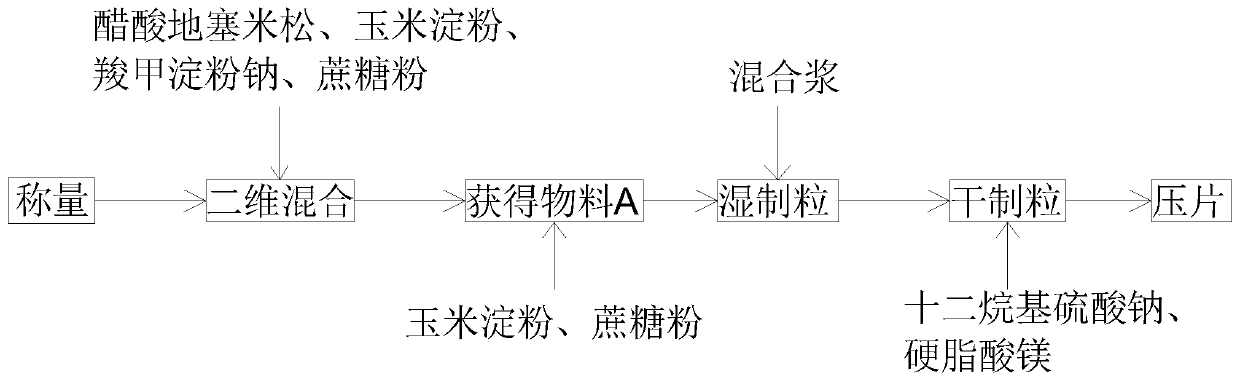

Dexamethasone acetate tablet and preparation method thereof

InactiveCN110742869AHigh dissolution rateThe appearance is complete and smoothOrganic active ingredientsAntipyreticCorn starchSucrose

The invention discloses a dexamethasone acetate tablet and a preparation method thereof. The dexamethasone acetate tablet is prepared from the following raw materials in percentage by weight: 0.62% ofdexamethasone acetate, 68.00% of corn starch, 29.56% of sucrose, 0.99% of carboxymethyl starch sodium, 0.74% of magnesium stearate, and 0.09% of lauryl sodium sulfate. The preparation method of the dexamethasone acetate tablet includes the following steps that micronization treatment of the dexamethasone acetate is realized firstly through the wall breaking of the raw materials, the obtained dexamethasone acetate is fully mixed with the corn starch raw materials to improve dissolution of the tablet, at the same time, when the dexamethasone acetate is integrated with the corn starch during preparation, an overall shape is protected, overall efficacy being not prone to being losing is protected, it is ensured that the appearance of the tablet is complete and smooth with uniform color, moisture content is less than or equal to 5.0%, the content is 93.0-107.0%, and brittleness is less than or equal to 0.8%.

Owner:安徽金太阳生化药业有限公司

Fast flower harvesting device and harvesting method thereof

PendingCN111108908APicking made easySimple structurePicking devicesAgricultural scienceAgricultural engineering

The invention discloses a fast flower harvesting device and a harvesting method thereof. The device comprises a cutting part and a suction part, wherein the suction part comprises a power unit and a vertically-arranged suction pipe; the power unit sucks gas in the suction pipe; the cutting part comprises a handle and blades connected to the handle; the blades include the fixed blade fixedly connected with the handle and the movable blade matched with the fixed blade; the fixed blade and the movable blade are arranged above a straw; and the movable blade moves in the horizontal direction. According to the fast flower harvesting device and the harvesting method thereof, fast crop harvesting can be realized; pickers and picked objects are not injured and damaged in a harvesting process; the device is simple in structure and convenient to use; and when in use, the picked objects can be easily picked by only taking the device in the hand and aligning the device to the picked objects, so that time and labor are saved and the defect in mechanical picking of crops such as flowers is made up for.

Owner:河南省中谦电力发展有限公司

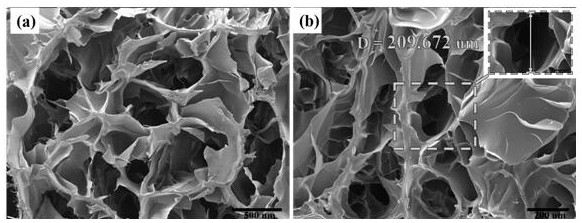

Lithium ion battery preparation method based on macropore carbon electrode

InactiveCN104681872AReduce usageLower internal resistanceFinal product manufactureCell electrodesInternal resistanceAdhesive

The invention relates to a modern battery industry, and in particular relates to a lithium ion battery preparation method based on a macropore carbon electrode. The lithium ion battery preparation method comprises the following steps: 1, preparation of raw materials; 2, preparation of SiO2; 3, preparation of C / SiO2; and 4, preparation of C / SiO2 / Sb2O3. According to the lithium ion battery preparation method, electric active substances are introduced into a macropore structure, so that the use of an adhesive can be avoided, and the internal resistance of the battery can be reduced; furthermore, the forms of the electric active substances can be effectively protected, so that the stability of the battery is enhanced; by the macropore structure, electrolyte can penetrate into the electrode to be a necessary channel for lithium ion transmission.

Owner:掌蕴东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com