Aortic valve stents to prevent paravalvular leaks

A technology for aorta and valves, which is applied in the field of medical devices, can solve problems such as valve performance degradation, increased sheath diameter, and difficulty in sheathing, achieving good compliance and shape memory performance, reducing the risk of vascular complications, and avoiding valve stents deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

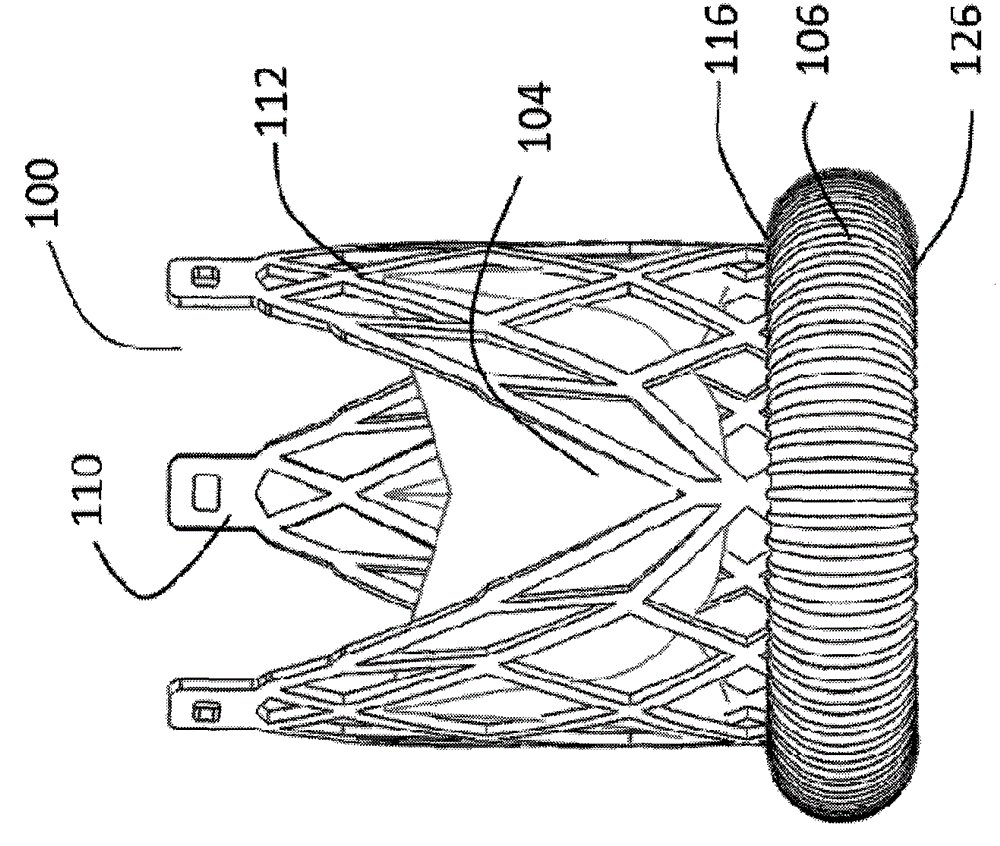

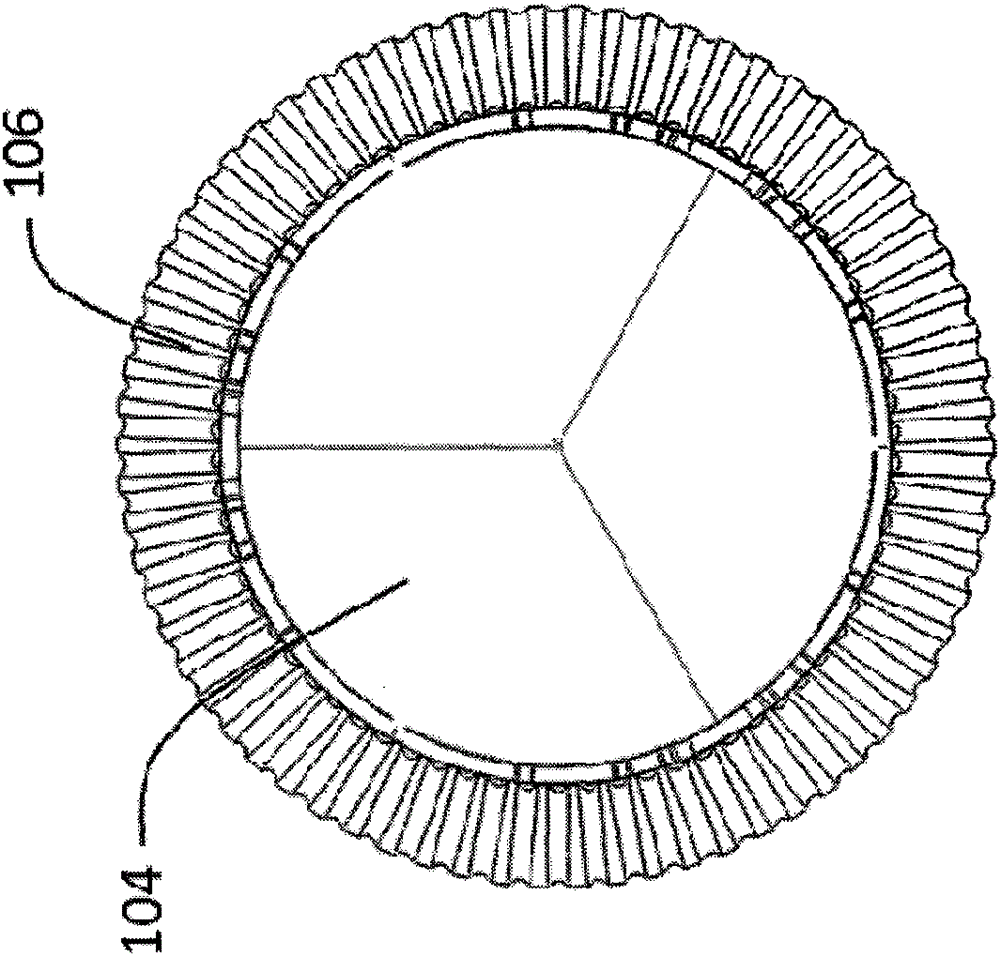

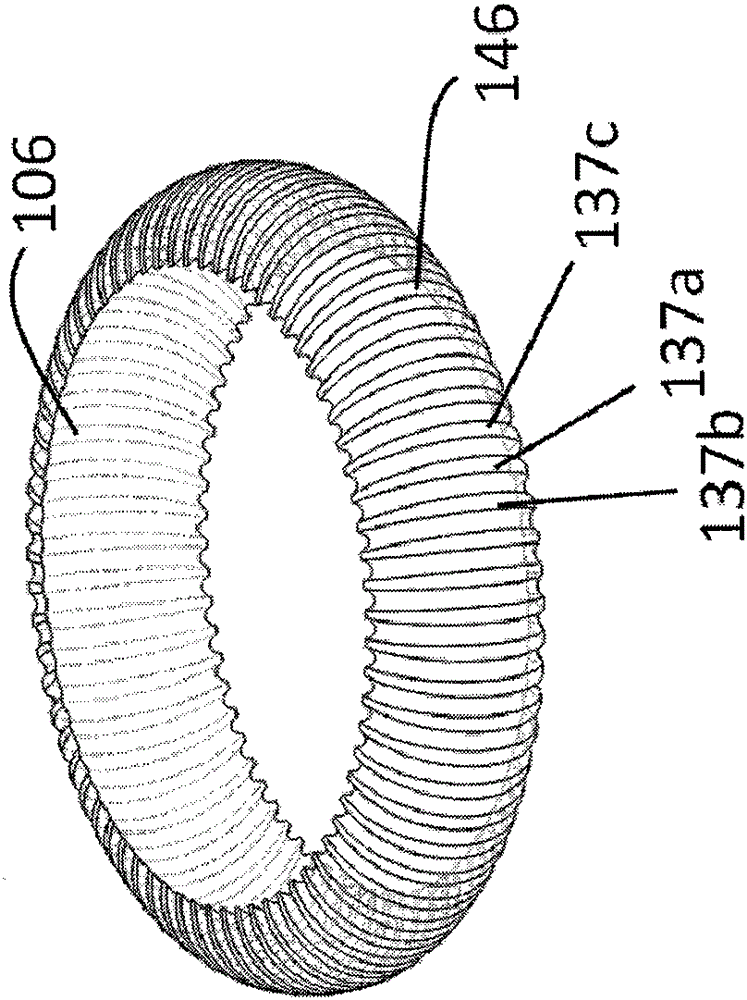

[0053] Such as Figure 1a and Figure 1b As shown, an aortic valve stent 100 for preventing paravalvular leakage includes a stent 110 and an artificial valve 104, the stent 110 is composed of a plurality of grid units 112, and the artificial valve 104 is connected to the grid unit 112, the bottom of the bracket 110 is provided with a sealing unit 106, the sealing unit 106 is made of metal memory material and covered with a film, in the natural state, the sealing unit 106 is along the axial direction of the bracket It is arched outward and has a ring structure along the circumference of the bracket. One end of the sealing unit 106 is free and is a free end 116, and the other end of the sealing unit 106 is fixed to the bottom of the bracket 110 by a fixing member, which is fixed end 126, when the sealing unit 106 is compressed into the sheath tube, the free end 116 of the sealing unit 106 turns around the fixed end 126 toward the bottom end of the bracket, so that the sealing un...

specific Embodiment 2

[0056] Such as Figure 6a and Figure 6b As shown, an aortic valve stent 100 for preventing paravalvular leakage includes a stent 110 and an artificial valve 104, the stent 110 is composed of a plurality of grid units 112, and the artificial valve 104 is connected to the grid unit 112, a sealing unit 206 is provided at the bottom of the bracket 110. The sealing unit 206 is made of metal memory material and covered with a film. In the natural state, the sealing unit 206 is along the axial direction of the bracket. It is arched outward and has a ring structure along the circumference of the bracket. One end of the sealing unit 206 is free, which is a free end 216, and the other end of the sealing unit 206 is fixed to the bottom of the bracket 110 by a fixing member, which is fixed end 226, when the sealing unit 206 is compressed into the sheath, the free end 216 of the sealing unit 206 turns around the fixed end 226 toward the bottom end of the bracket, so that the sealing unit...

specific Embodiment 3

[0062] Such as Figure 11a and Figure 11b As shown, an aortic valve stent 100 for preventing paravalvular leakage includes a stent 110 and an artificial valve 104, the stent 110 is composed of a plurality of grid units 112, and the artificial valve 104 is connected to the grid unit 112, a sealing unit 306 is provided at the bottom of the bracket 110. The sealing unit 306 is made of metal memory material and covered with a film. In the natural state, the sealing unit 306 is along the axial direction of the bracket. Outwardly arched, it is a ring structure along the circumference of the bracket, one end of the sealing unit 306 is free, which is a free end 316, and the other end of the sealing unit 306 is fixed to the bottom of the bracket 110 by a fixing member, which is fixed end 326, when the sealing unit 306 is compressed into the sheath, the free end 316 of the sealing unit 306 turns around the fixed end 326 toward the bottom end of the bracket, so that the sealing unit 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com