Medium density fiber board made from bamboo

A fiberboard, medium-density technology, applied in fiber raw materials, fiber raw material processing, pretreatment of molding materials, etc., can solve the problems of brittleness of wear-resistant paper or decorative paper, increase production cost, reduce production efficiency, etc. cost, wood saving, and the effect of increasing the income of bamboo farmers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through embodiment and accompanying drawing. It should be noted that these embodiments are not intended to limit the protection scope of the present invention, and the protection scope of the present invention shall prevail in the appended claims.

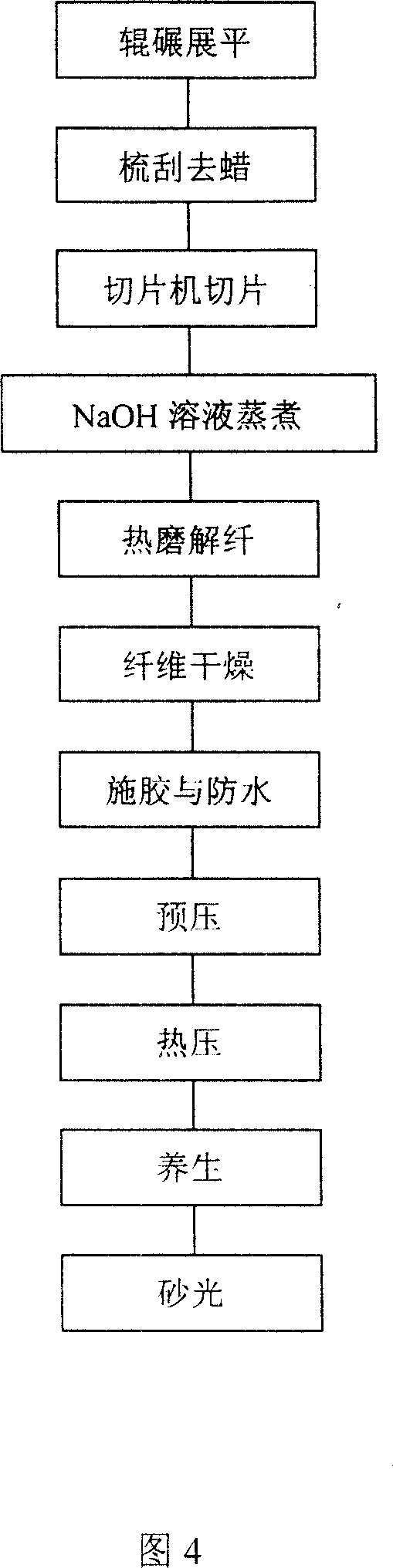

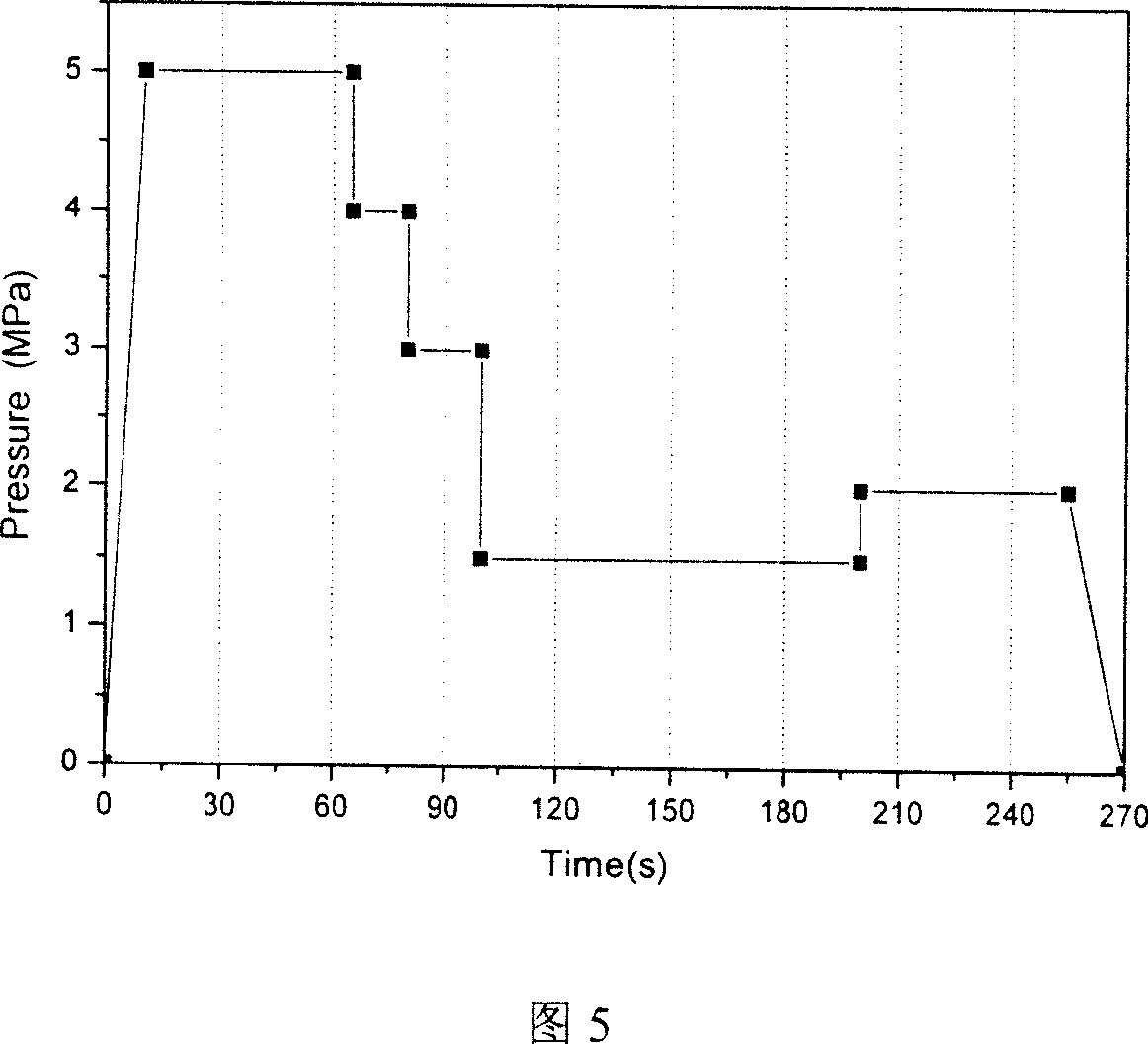

[0033]After the miscellaneous bamboo is rolled and combed to remove part of the bamboo wax on the surface, the miscellaneous bamboo is sliced by a disc-type bamboo wood chipper, and the temperature is 120°C. NaOH accounts for 5% of the weight of the bamboo slices and pressurized for 0.5 MPa cooking 15min, the bamboo chip that the cooking is crossed is dropped into QM6 thermal grinder and carry out thermal grinding and defibrating, obtain bamboo fiber and dry; To the bamboo fiber spraying 21.5 weight parts of 100 weight parts by 5 weight parts antifungal agents, 1.5 weight parts part curing agent, 3 parts by weight paraffin emulsion waterproofing agent and 12 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com