Biomimetic electronic skin medical stent material with self-repairing function and preparation method thereof

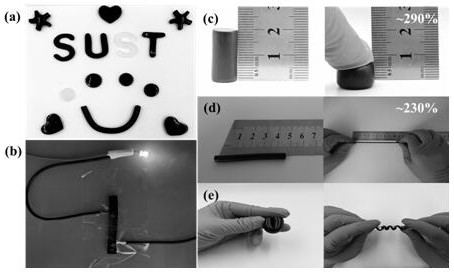

A scaffold material and self-repair technology, applied in medical science, prosthesis, etc., can solve problems such as poor mechanical properties, uncertain antigen elimination, unsuitable control of degradation rate, etc., to prevent shedding, protect cell shape, and good self-repair performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of acidified carbon nanotube dispersion: Accurately weigh 1.0 g of multi-walled carbon nanotubes (MWCNTs), 50.0 g of concentrated H 2 SO 4 (98%), 100 g HNO 3 (65~68%) in a three-necked flask, heated to 50°C, and the reaction time was 15 hours; after the reaction was complete, centrifuged at a gradient speed, and the conditions of the gradient speed centrifugation were: ① centrifuge at 5000 rpm for 60 min, and filter; ② add 100.0 mL Centrifuge ultrapure water at 8000 rpm for 60 min, filter; ③ add 100.0 mL of ultrapure water, centrifuge at 10000 rpm for 60 min, repeat each centrifugation step 3 times, store in freeze-dry; weigh 0.1 g of acidified carbon Nanotube powder, in 200 mL H 2 Sonicate in O for 0.5 h to prepare a 0.05% (m / v) acidified multi-walled carbon nanotube dispersion and store it for future use;

[0040] (2) Preparation of acidified carbon nanotube / PEDOT:PSS composite dispersion: accurately measure 10.0 mL of ultrapure water into a single-...

Embodiment 2

[0045] (1) Preparation of acidified carbon nanotube dispersion: Accurately weigh 3.0 g of multi-walled carbon nanotubes (MWCNTs), 250.0 g of concentrated H 2 SO 4 (98%), 20 g HNO 3 (65~68%) in a three-neck flask, heated to 80°C, and the reaction time was 10 hours; after the reaction was complete, centrifuged at a gradient speed, the conditions were: ① centrifuge at 3000 rpm for 30 min, and filter; ② add 300.0 mL ultrapure water , centrifuge at 6500 rpm for 30 min, filter; ③ add 300.0 mL of ultrapure water, centrifuge at 9000 rpm for 30 min, repeat each centrifugation step 4 times, freeze-dry and store; weigh 0.5 g of acidified carbon nanotubes powder, in 100mL H 2 Supersonicate in O for 1.0 h to prepare a 0.5% (m / v) acidified multi-walled carbon nanotube dispersion, which is stored for subsequent use;

[0046] (2) Preparation of acidified carbon nanotube / PEDOT:PSS composite dispersion: accurately measure 50.0 mL of ultrapure water into a single-necked flask, and accuratel...

Embodiment 3

[0051] (1) Preparation of acidified carbon nanotube dispersion: Accurately weigh 5.0 g of multi-walled carbon nanotubes (MWCNTs), 150.0 g of concentrated H 2 SO 4 (98%), 50 g HNO 3 (65~68%) in a three-neck flask, heated to 100°C, and the reaction time was 5 hours; after the reaction was complete, centrifuged at a gradient speed, the conditions were: ①Centrifuge at 1000 rpm for 10 min, and filter; ②Add 100.0 mL ultrapure water , centrifuge at 5000 rpm for 10 min, filter; ③ add 500.0 mL of ultrapure water, centrifuge at 8000 rpm for 10 min, repeat each centrifugation step 3 times, freeze-dry and store; weigh 1.0 g of acidified carbon nanotubes powder, in 50mL H 2 Ultrasound in O for 2.0 h, prepare a 2.0% (m / v) acidified multi-walled carbon nanotube dispersion, and store it for later use;

[0052] (2) Preparation of acidified carbon nanotube / PEDOT:PSS composite dispersion: accurately measure 25.0 mL of ultrapure water into a single-necked flask, and accurately pipette 5.0 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com