3D printed mechanical bionic auricle cartilage tissue engineering scaffold and manufacturing method thereof

A 3D printing and cartilage tissue technology, applied in tissue regeneration, medical science, additive processing, etc., to achieve the effect of saving printing materials, excellent printability, and reducing support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Use 123D Design 2.2.14 to design a cube model of 8mm×8mm×3mm, select the PLCL-PCL blend with a ratio of 90:10 as the raw material (CN201910139657.9), and print it by melt extrusion deposition (FDM) Method, using a desktop 3D printer to print at 170°C, printing speed 2mm / s, and 70% filling conditions, to obtain a cube model with a porous and borderless structure, measure and print to obtain the actual three-dimensional size value of the model, and according to the size data of the original model, Calculate the shrinkage rates on the X, Y and Z axes in 3D printing respectively, and the results are: length (X axis), 6.75%±0.51%; width (Y axis), 10.82%±0.43%; height (Z axis ), 2.35%±0.73%.

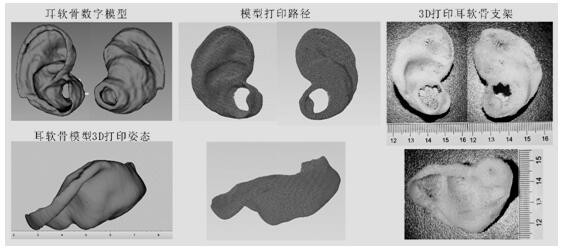

[0035] 2. In Materialize Magics24.0, convert the acquired auricle cartilage scan file into a digital model file and adjust its contact angle with the horizontal plane to maximize the contact area with the horizontal plane; according to the X, Y and Z calculated in step 1) The result...

Embodiment 2

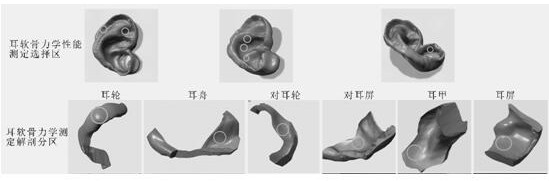

[0037] 1. In Magics 24.0, the adjusted auricle cartilage digital model in step 2) of Example 1 is divided into digital model areas of the tragus, antitragus, helix, antihelix, concha and scaphoid according to the anatomical structure, and The maximum area of the cylindrical area with a flat structure can be selected as a reference, and the area of the digital model of the tragus, antitragus, helix, antihelix, concha and scaphoid is selected separately to meet the mechanical performance test requirements of the bracket . According to the shrinkage results of the 90:10 PLCL-PCL blend 3D printed 70% filling rate cube bracket on the X, Y and Z axes, the digital model of the selected area is scaled and adjusted, and the 3D is 3D according to the above process and conditions Print borderless porous scaffolds.

[0038] 2. The model bracket of the selected area of the mechanical test obtained by 3D printing in step 1) is tested on the mechanical performance of compression defor...

Embodiment 3

[0040] 1. Use 123D Design 2.2.14 to design a cube model with a porous frameless structure of 8mm×8mm×3mm, select the PLCL-PCL blend with a ratio of 80:20 as the raw material, and print it by melt extrusion deposition (FDM) , using a desktop 3D printer to print the model with a filling rate of 70% at 170°C and a printing speed of 2mm / s, measure and print the actual 3D size of the model, and calculate the X , Y and Z three-axis shrinkage, the results are: length (X axis), 6.75% ± 0.51%; width (Y axis), 10.82% ± 0.43%; height (Z axis), 2.35% ± 0.73% .

[0041] 2. In Magics24.0, convert the acquired auricular cartilage scan file into a digital model file and adjust its contact angle with the horizontal plane to maximize the contact area with the horizontal plane; according to the X, Y and Z three dimensions calculated in step 1), The shrinkage rate results on the axis, after zooming and adjusting the digital model of the auricle cartilage, output it as a 3D printing STL format fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com