Preparation technology for environment-friendly high polymer material packaging bag

A polymer material and preparation technology, which is applied in the field of environmentally friendly polymer material packaging bag preparation technology, can solve the problems of large environmental pollution, which cannot be completely reduced, and polymer plastic materials are not easy to degrade, so as to reduce production costs. Effect of printing error and reducing film curl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

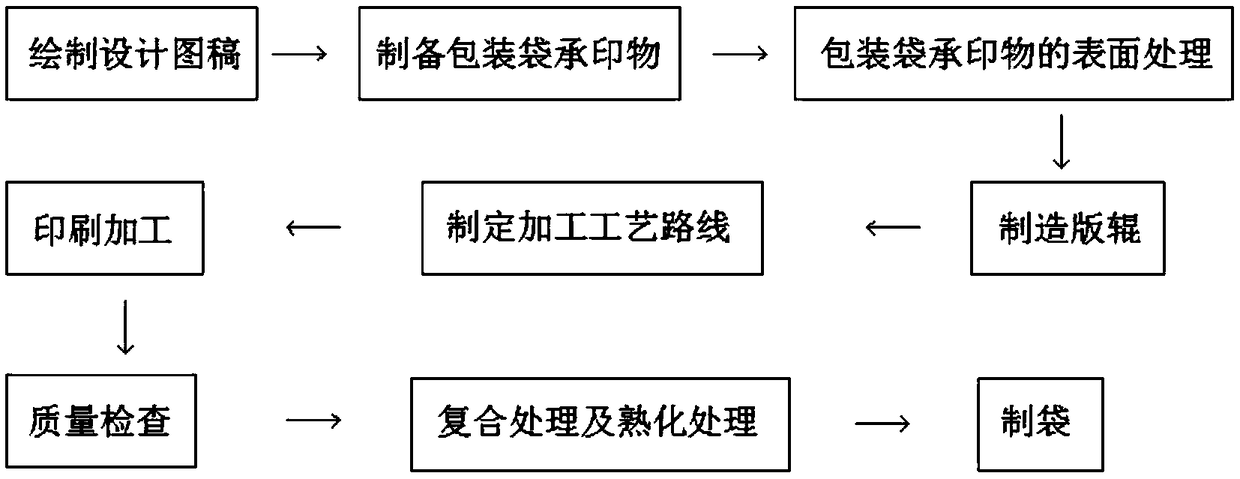

[0037] Process for preparing environment-friendly polymer material packaging bag

[0038] Step 1: Draw the design artwork

[0039] Use computer software to draw design drawings according to the requirements for printing on the surface of the packaging bags and the specifications of the packaging bags, and review the design drawings to ensure that the parameters of the design drawings are accurate;

[0040] Step 2: Prepare packaging bag substrate

[0041] First add 40 parts by mass of polyhydroxyalkanoate and 8 parts by mass of coupling agent into the container, raise the temperature in the container to 50 degrees Celsius, and stir at low speed for 18 minutes after the temperature rises. The speed in the container is 220 rpm, low-speed stirring, then ultrasonic dispersion treatment, ultrasonic dispersion treatment temperature is 45 degrees Celsius, ultrasonic dispersion treatment time is 30 minutes, after ultrasonic dispersion treatment, medium temperature drying treatment is carried o...

Embodiment 2

[0057] Process for preparing environment-friendly polymer material packaging bag

[0058] Step 1: Draw the design artwork

[0059] Use computer software to draw design drawings according to the requirements for printing on the surface of the packaging bags and the specifications of the packaging bags, and review the design drawings to ensure that the parameters of the design drawings are accurate;

[0060] Step 2: Prepare packaging bag substrate

[0061] First put 45 parts by mass of polyhydroxyalkanoate and 9 parts by mass of coupling agent into the container, raise the temperature in the container to 50 degrees Celsius, and stir at low speed for 18 minutes after the temperature rises. The speed in the container is 220 rpm, low-speed stirring, then ultrasonic dispersion treatment, ultrasonic dispersion treatment temperature is 45 degrees Celsius, ultrasonic dispersion treatment time is 30 minutes, after ultrasonic dispersion treatment, medium temperature drying treatment is carried o...

Embodiment 3

[0077] Process for preparing environment-friendly polymer material packaging bag

[0078] Step 1: Draw the design artwork

[0079] Use computer software to draw design drawings according to the requirements for printing on the surface of the packaging bags and the specifications of the packaging bags, and review the design drawings to ensure that the parameters of the design drawings are accurate;

[0080] Step 2: Prepare packaging bag substrate

[0081] First add 50 parts by mass of polyhydroxyalkanoate and 10 parts by mass of coupling agent into the container, raise the temperature in the container to 50 degrees Celsius, stir at low speed for 18 minutes after the temperature rises, and the speed in the container when stirring at low speed is 220 rpm, low-speed stirring, then ultrasonic dispersion treatment, ultrasonic dispersion treatment temperature is 45 degrees Celsius, ultrasonic dispersion treatment time is 30 minutes, after ultrasonic dispersion treatment, medium temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com