Print nozzle system and mixed spraying printing technology of adjustable soft hollow tube support

A technology for printing nozzles and nozzles, which is applied in the fields of mechanical automation, biotechnology, and tissue engineering, and can solve the problems of difficult customization of hydrogel tubular structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

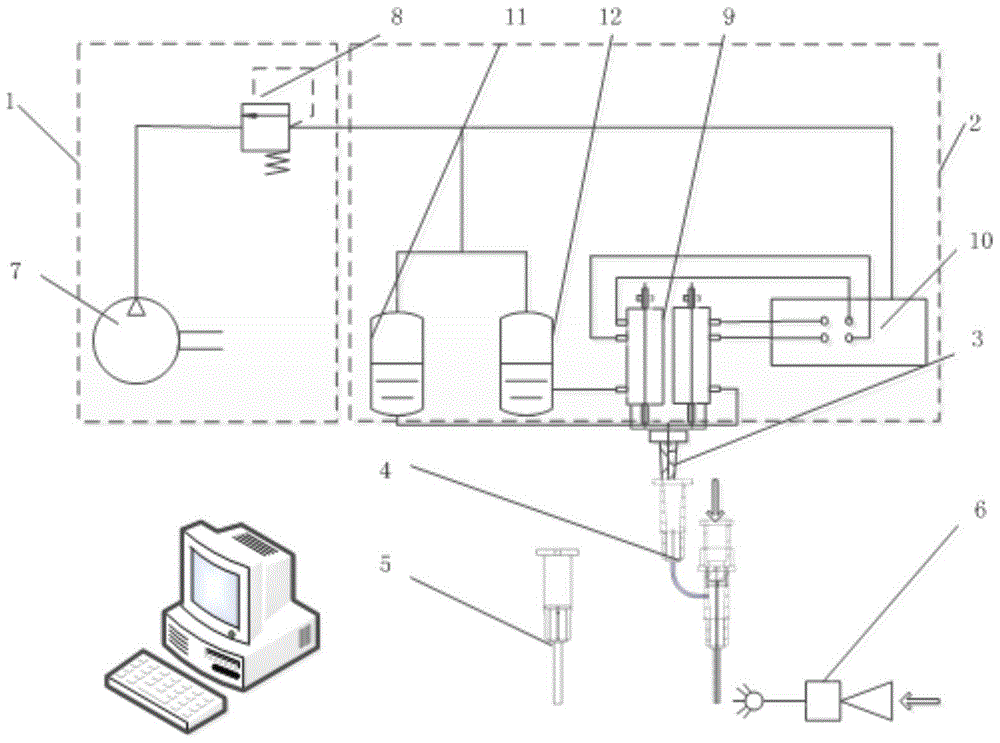

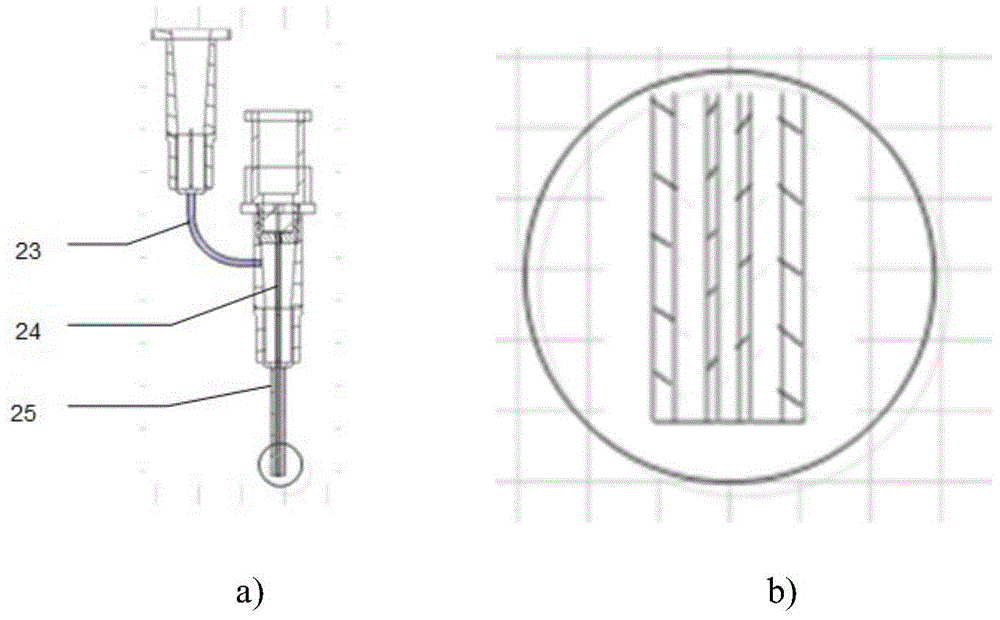

[0037] refer to figure 1 As shown, the pneumatic power source 1 provides power for the system. The sodium alginate of 0.2%-0.6% (m / v) is placed in the storage tank A 11, the calcium chloride of 2%-6% (m / v) is placed in the storage tank B 12, under the action of gas pressure Next, the feeding device 2 flows through the mixing device 3 to complete the thorough mixing of 0.2%-0.6% (m / v) sodium alginate and 2%-6% (m / v) calcium chloride. 0.2%-0.6% (m / v) sodium alginate mixed with 2%-6% (m / v) calcium chloride through needle one (23), 2%-6% (m / v) calcium chloride Through needle two 24, the sodium alginate of 0.2%-0.6% (m / v) and the calcium chloride mixture of 2%-6% (m / v) and 2%-6% (m / v) v) Calcium chloride contacts and undergoes a chemical reaction to form the inner structure of the hollow tube. The calcium chloride of 2%-6% (m / v) is ejected from spray device (6), and the sodium alginate of 0.2%-0.6% (m / v) and the sodium alginate of 2%-6% (m / v) When the calcium chloride mixture c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com