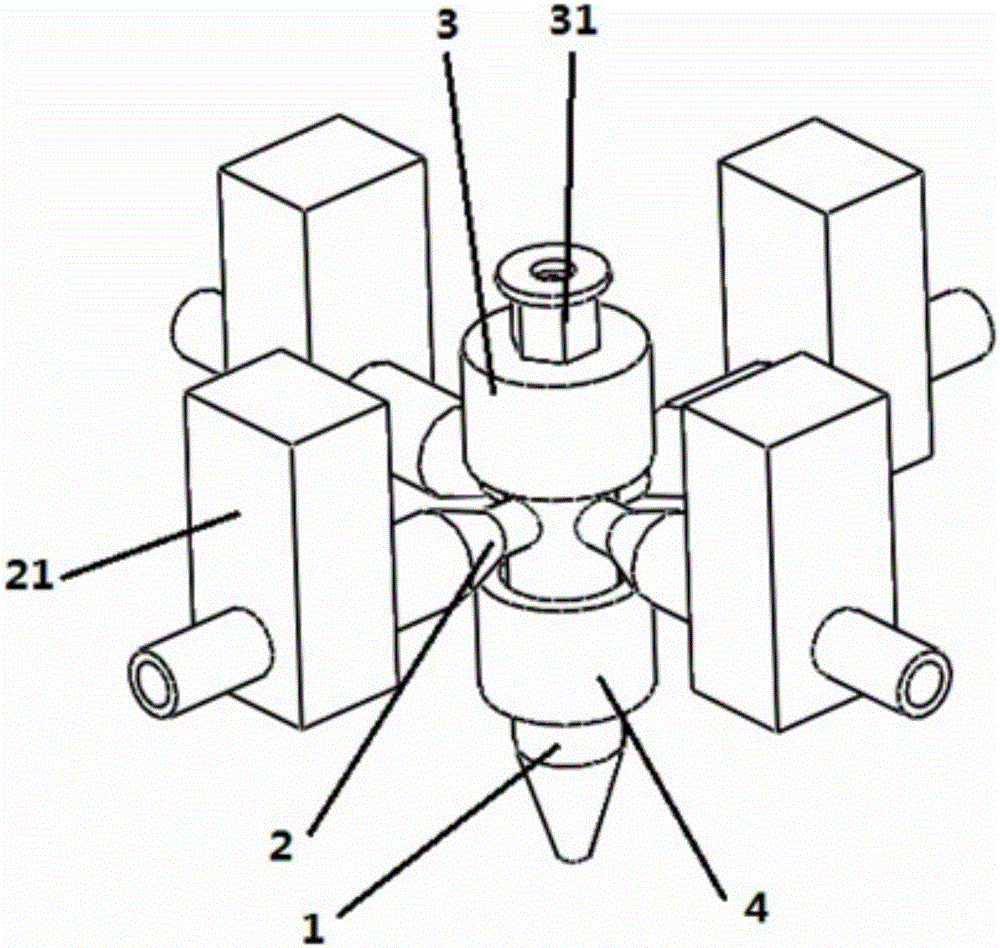

Multi-material 3D printing sprayer and operating method thereof

A 3D printing, multi-material technology, applied in the direction of 3D object support structure, additive processing, additive manufacturing, etc., can solve the problems of increased number of nozzles, high cost, increased system complexity, etc., to improve product quality, simple structure, Ingredient controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0023] Embodiment 2: An operation method of a multi-material 3D printing nozzle, print the 3D printing nozzle on the 3D printer, and connect the feeding channel and the air pressure quick connector, before printing, open the ultrasonic vibration ring, and connect through each feeding channel The pressure pump transports the material to be printed to the proportional valve. At this time, the proportional valve is closed, and the material does not enter the inner cavity of the nozzle body. The open section of the proportional valve is controlled by the program, so that each material enters according to the required ratio. In the inner cavity of the main body of the nozzle, under the vibration of the ultrasonic vibrating head of the ultrasonic vibration ring, the materials input from different feeding ports are mixed rapidly and evenly, and at the same time, the pressure gas introduced through the pneumatic quick joint extrudes the mixed material to the nozzle port to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com