Tube drawing auxiliary device applied to on-site mixed emulsion explosive loading procedure

A technology of emulsified explosives and on-site mixing, which is applied in blasting and other directions, and can solve the problems of friction between the drug delivery pipe and the blast hole rock, high labor intensity, etc., and achieve the effects of less loss, less risk, and lower use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

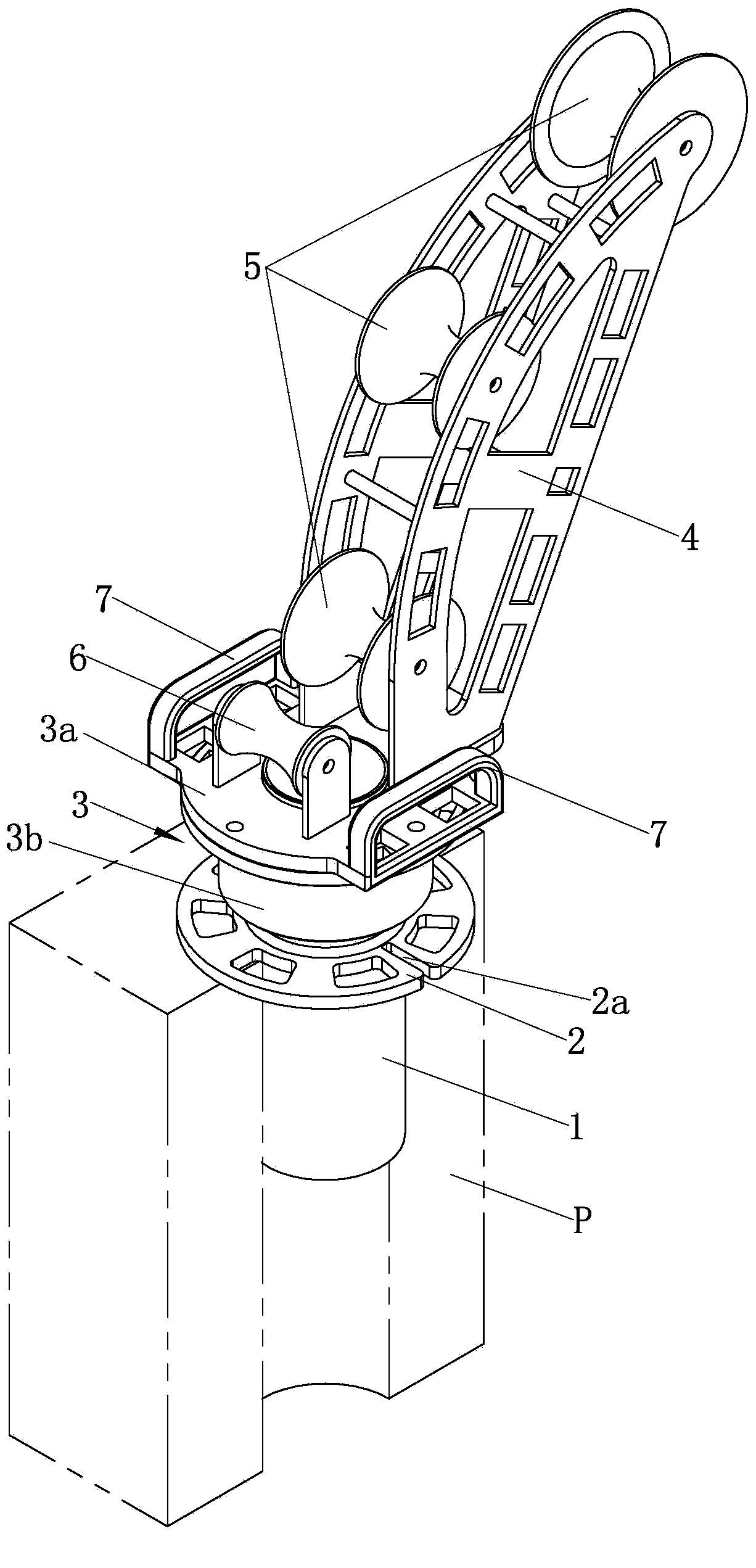

[0019] like figure 1 As shown, an auxiliary device for extubation used in the charging process of mixing emulsified explosives on site is mainly composed of a positioning tube 1, a support plate 2, a rotating support 3, a bracket 4, a guide wheel 5, a positioning wheel 6 and a handle 7, Wherein the positioning pipe 1 is arranged vertically, and may preferably be a steel pipe, and a support plate 2 is fixedly sleeved on the upper end of the positioning pipe 1 . In addition, the supporting plate 2 is provided with a plurality of threading grooves 2a for detonating materials, and these threading grooves 2a for detonating materials are evenly distributed along the circumferential direction of the supporting plate 2 and run through the upper and lower surfaces of the supporting plate 2 . The rotating support 3 is composed of an upper disc part 3a and a lower slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com