Grooving blade

A blade and grooving technology, applied in milling cutters, milling machine equipment details, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, and the machining accuracy cannot be guaranteed, and achieve the effects of less loss, improved production efficiency, and high machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

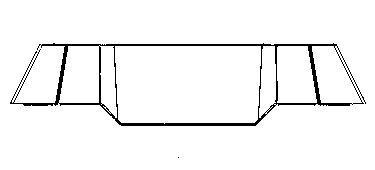

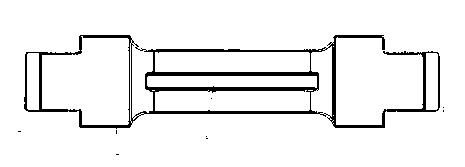

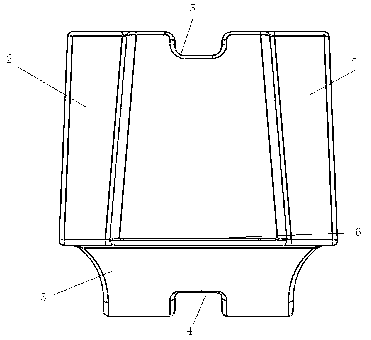

[0011] Such as figure 1 , 2 , 3, 4 shown

[0012] The grooving blade of this embodiment has an integrally formed structure. The blade main body 1 is a four-sided platform with an isosceles trapezoidal side. The front and rear sides of the blade main body are respectively provided with a "concave"-shaped boss 2. The boss cooperates with the groove on the milling cutter disc base to limit the longitudinal displacement of the blade. The bottom surface of the blade body is provided with a trapezoidal boss 3, and the bottom surface of the trapezoidal boss is provided with a bottom positioning groove. 4. A top positioning groove 5 is provided on the top surface of the blade main body. The above two positioning grooves 4, 5 cooperate with the positioning keys arranged on the milling cutter disc to limit the lateral displacement of the blade. The cutting edge of the blade 6 It is arranged on the bottom edge of the trapezoidal sides on the left and right sides of the blade main body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com