Anti-tearing non-woven fabric and preparation method thereof

A non-woven fabric and anti-tear technology, which is applied in the direction of non-woven fabrics, textiles, papermaking, fiber types, etc., can solve the problems of easy tearing and damage of non-woven fabrics, so as to improve the anti-tear performance and enhance the anti-tear Performance, effect of fabric pore size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of above-mentioned anti-tear nonwoven fabric, comprises the steps:

[0032] S1 prepares fiber net: prepare each raw material by weight: low-density polyethylene, hemp fiber, polypropylene, polyisobutylene, softening agent, reinforcing modifier, antistatic agent, lubricant, nano polytetrafluoroethylene, each The raw materials are melted, mixed and loosened, and then combed into a web by a carding machine to obtain a fiber web, and the fiber web is drawn by a drafting machine;

[0033] S2 spunlace: feed the fiber web drawn in step S1 into the spunlace area for the first spunlace and the second spunlace to form a non-woven fabric and dry it;

[0034] S3 cold bleaching: the non-woven fabric dried in the step S2 is immersed in the auxiliary agent and then subjected to cold pile treatment;

[0035] S4 washing: wash the cold-stacked non-woven fabric in step S3 for 2-3 times to remove residual additives;

[0036] S5 drying: put the non-woven fabric wash...

Embodiment 1

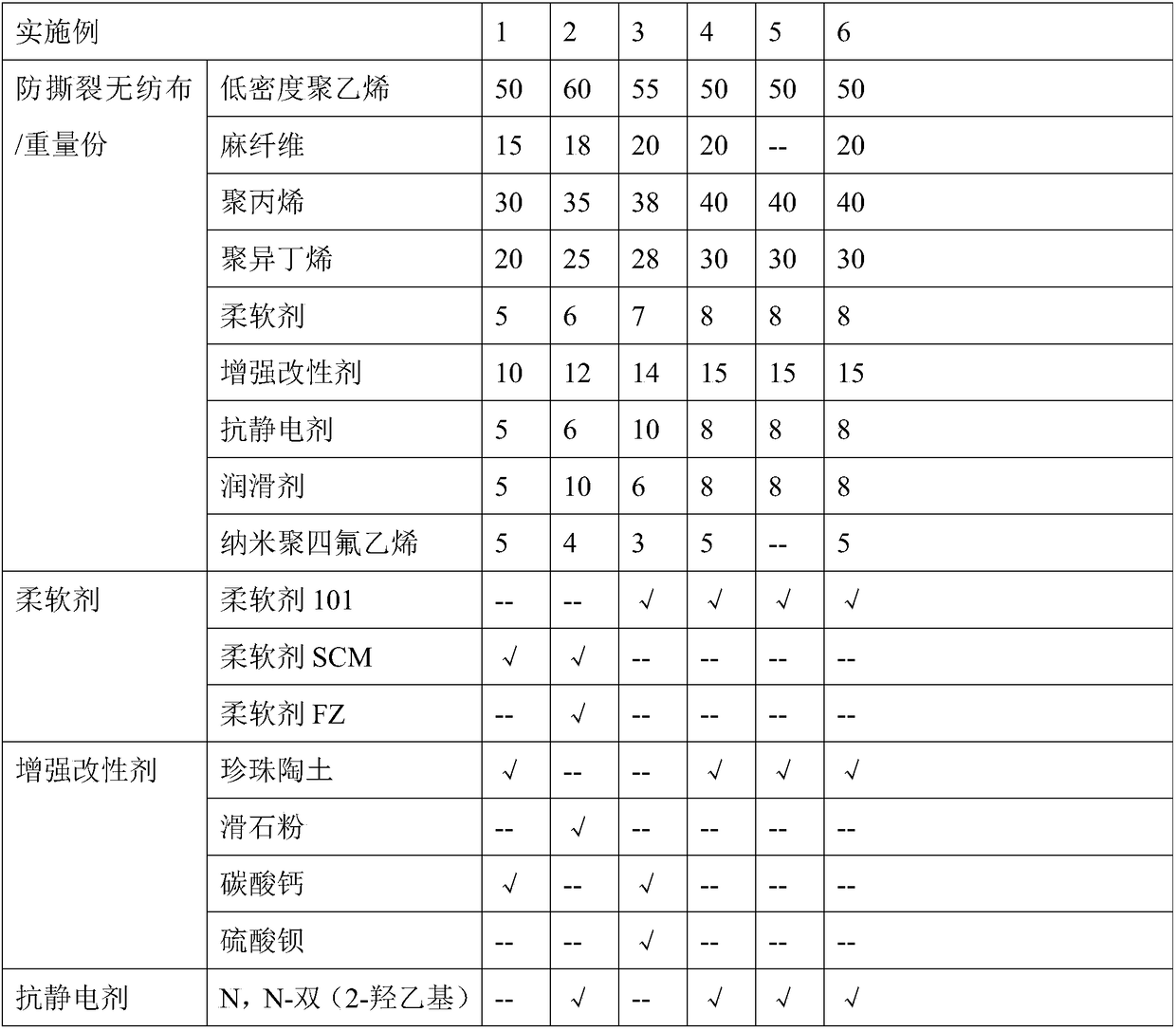

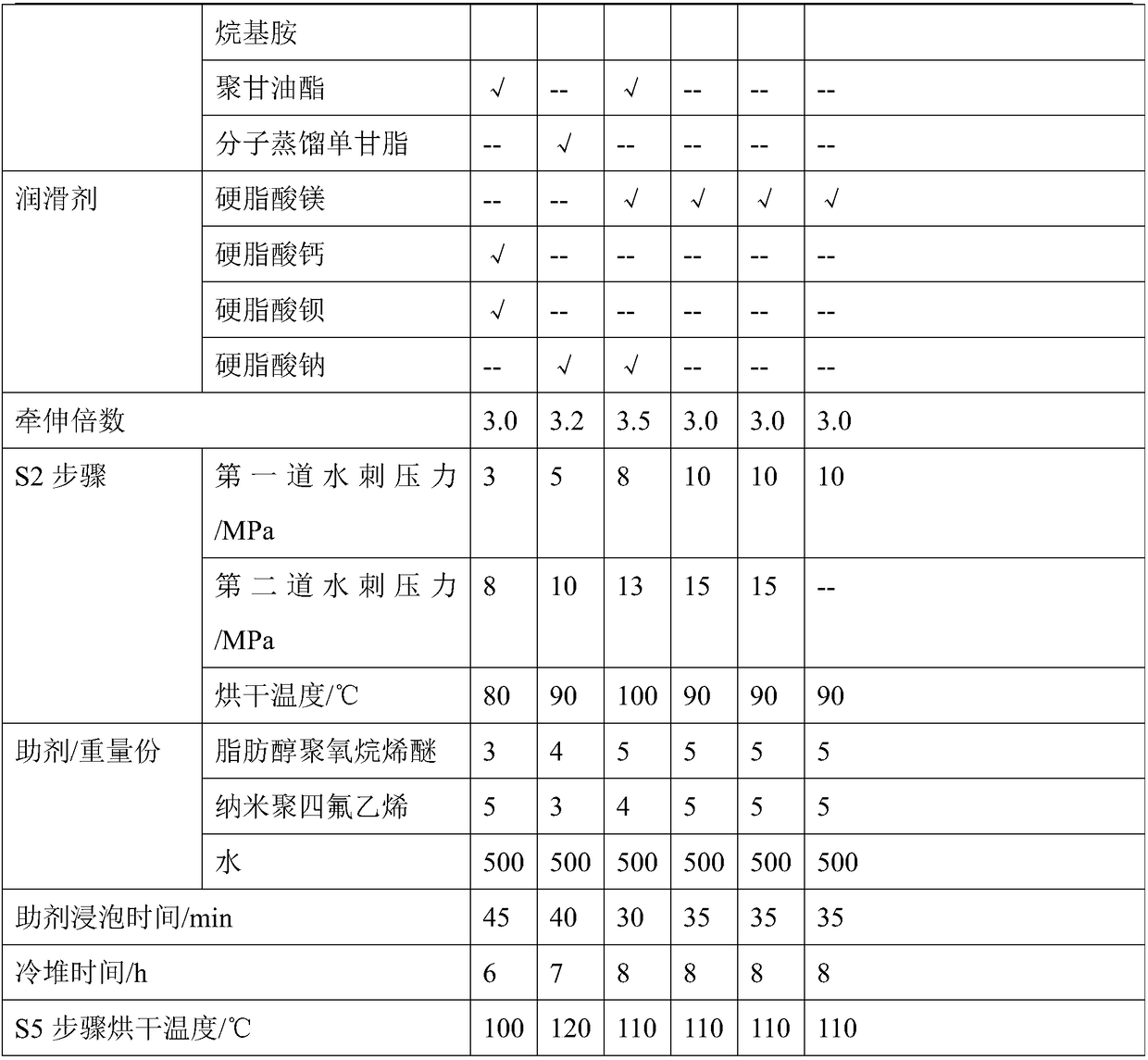

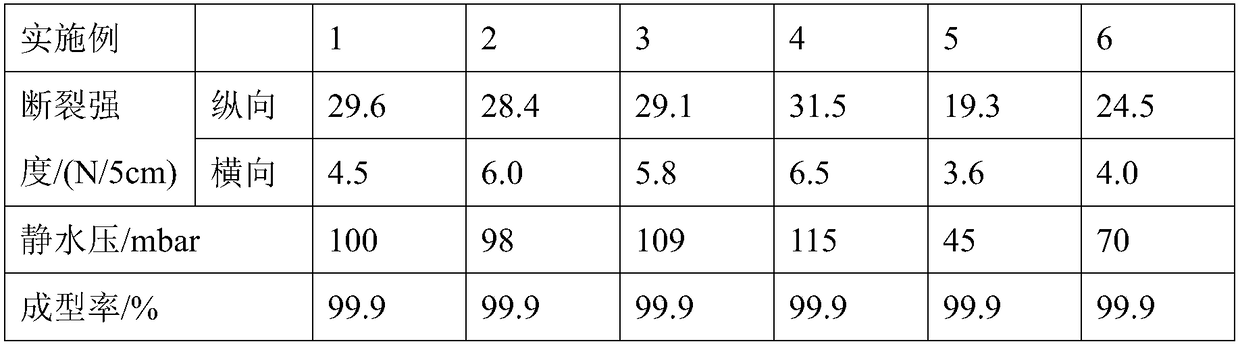

[0041] The concrete implementation parameter of embodiment 1-embodiment 6 is as shown in table 1, and wherein embodiment 1-embodiment 4 is the technical parameter that the present invention limits, does not add hemp fiber, nano polytetrafluoroethylene in embodiment 5, embodiment Spunlace was performed only once in 6, and examples 5-6 were comparative examples of the present invention.

[0042] Table 1 embodiment 1-embodiment 6 prepares the concrete implementation parameter of non-woven fabric

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com