Labyrinth-shaped spherical hollow filler

A labyrinth-like filling technology, which is applied in container filling methods, gas/liquid distribution and storage, fire rescue, etc., to reduce economic property and life losses, improve intrinsic safety, and inhibit diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

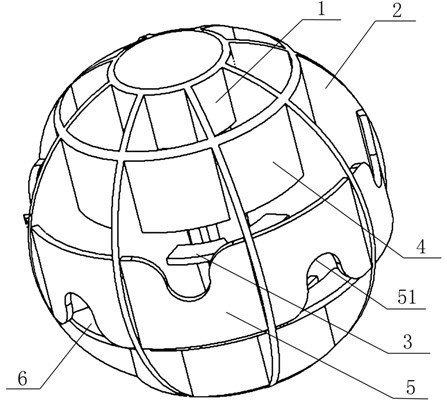

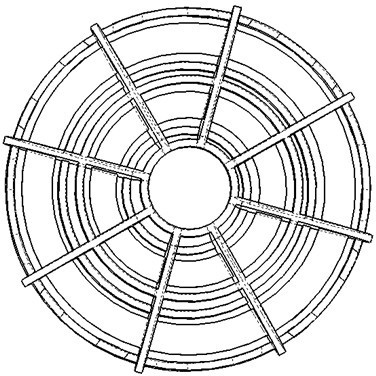

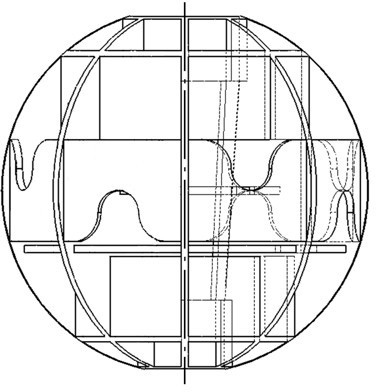

[0085] Such as Figure 1-3 As shown, the maze-shaped spherical hollow filling body is provided with coaxial tubular bodies 1 at both ends, and several fan-shaped bodies 2 are evenly connected around the outer circumference of the two tubular bodies 1, and each of the fan-shaped bodies 2 is vertically connected respectively. On the outer circumference of the two tubular bodies 1, and the axes of each fan-shaped body 2 and the two tubular bodies 1 are on the same plane; in the middle of the two tubular bodies 1, an annular body 3 and each of the The sectors 2 are connected, and the annular bodies 3 are respectively perpendicular to the axis of the tubular body 1 and the surface of the sector 2; a large tubular body 4 with a larger radius is arranged on the outside of each tubular body 1 ; A ring-shaped belt 5 is arranged at a position close to the apex of the fan-shaped body 2, and several concave notches 51 are arranged alternately on both sides of the annular belt 5, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com