Heat shrinkable multilayer film

A shrinkable, multi-layer film technology, applied in the direction of layered products, flexible coverings, rubber layered products, etc., can solve the problems of difficult separation of bottles and labels, poor appearance, breakage, etc., and achieve less physical property degradation and durability Excellent printability and excellent low-temperature shrinkage

Active Publication Date: 2009-09-23

PS JAPAN CORP

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Copolymers with a high proportion of (meth)acrylate content are more likely to be used in solvents used in printing inks when printing with oil-based printing inks (generally esters such as ethyl acetate and alcohols such as isopropanol) Intrusion, the film obtained by using the copolymer with a high proportion of (meth)acrylate content in the inner and outer layers (or inner and outer layers) and the intermediate layer may sometimes break when the printed film is taken up, or due to Improvement is expected due to poor appearance due to surface roughness of the printing surface

[0009] In addition, in recent years, from the viewpoint of reusing plastic containers represented by plastic bottles, research has been carried out to make the labels easy to tear, such as punching holes in the labels, and to make it easy to separate the bottles and labels. Patent Documents 2 to 4 describe an intermediate layer made of a resin containing rubbery elastomer dispersed particles and a large amount of (meth)acrylate in the continuous phase, and a resin made of a styrene-based monomer and a conjugated diene. The label of a heat-shrinkable multilayer film composed of a block copolymer composed of monomers and the inner and outer layers of the main body has the problem that the bottle and the label are difficult to separate because of the interlayer peeling when tearing. It is desired to improve the interlayer adhesion. Compatibility

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

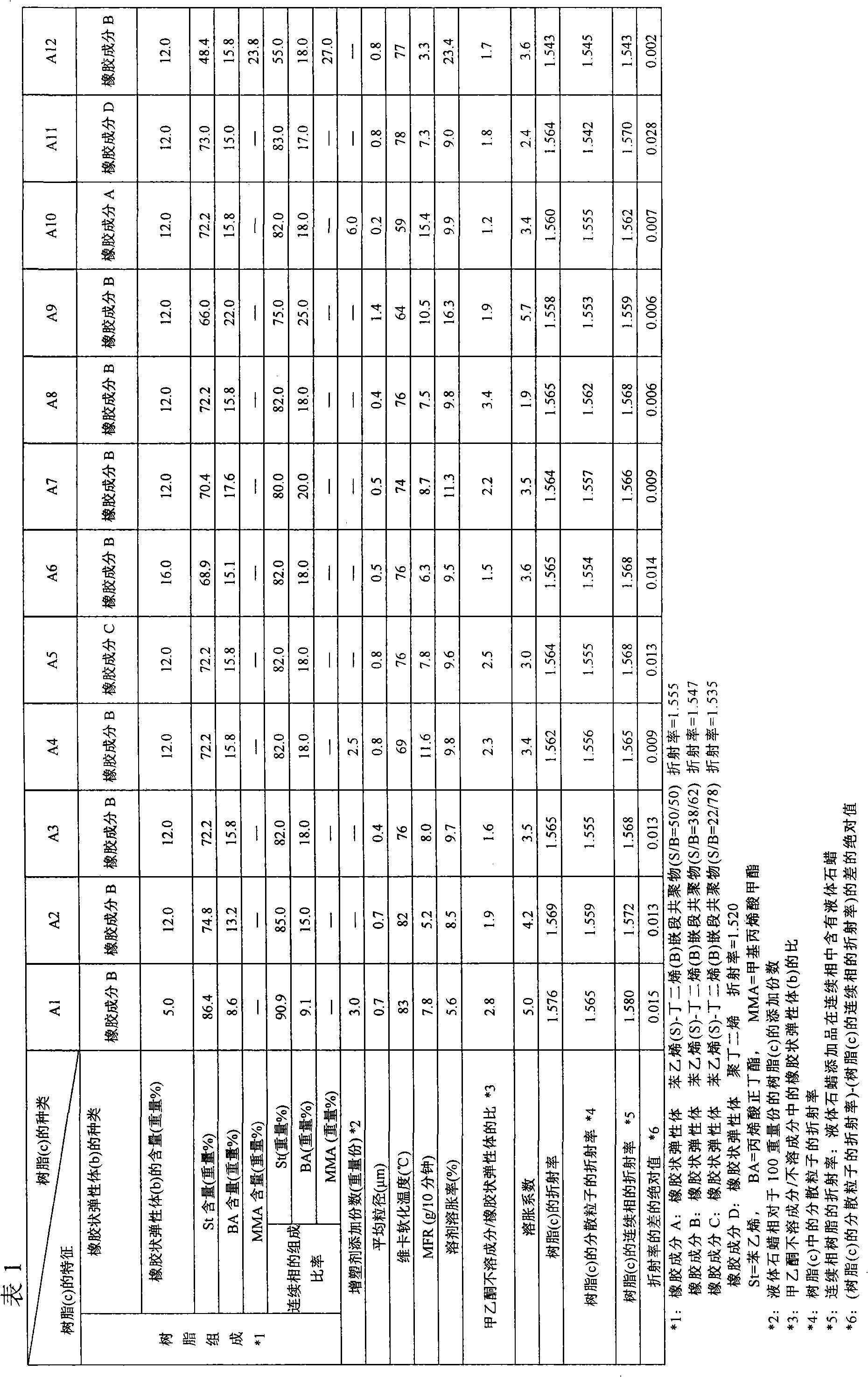

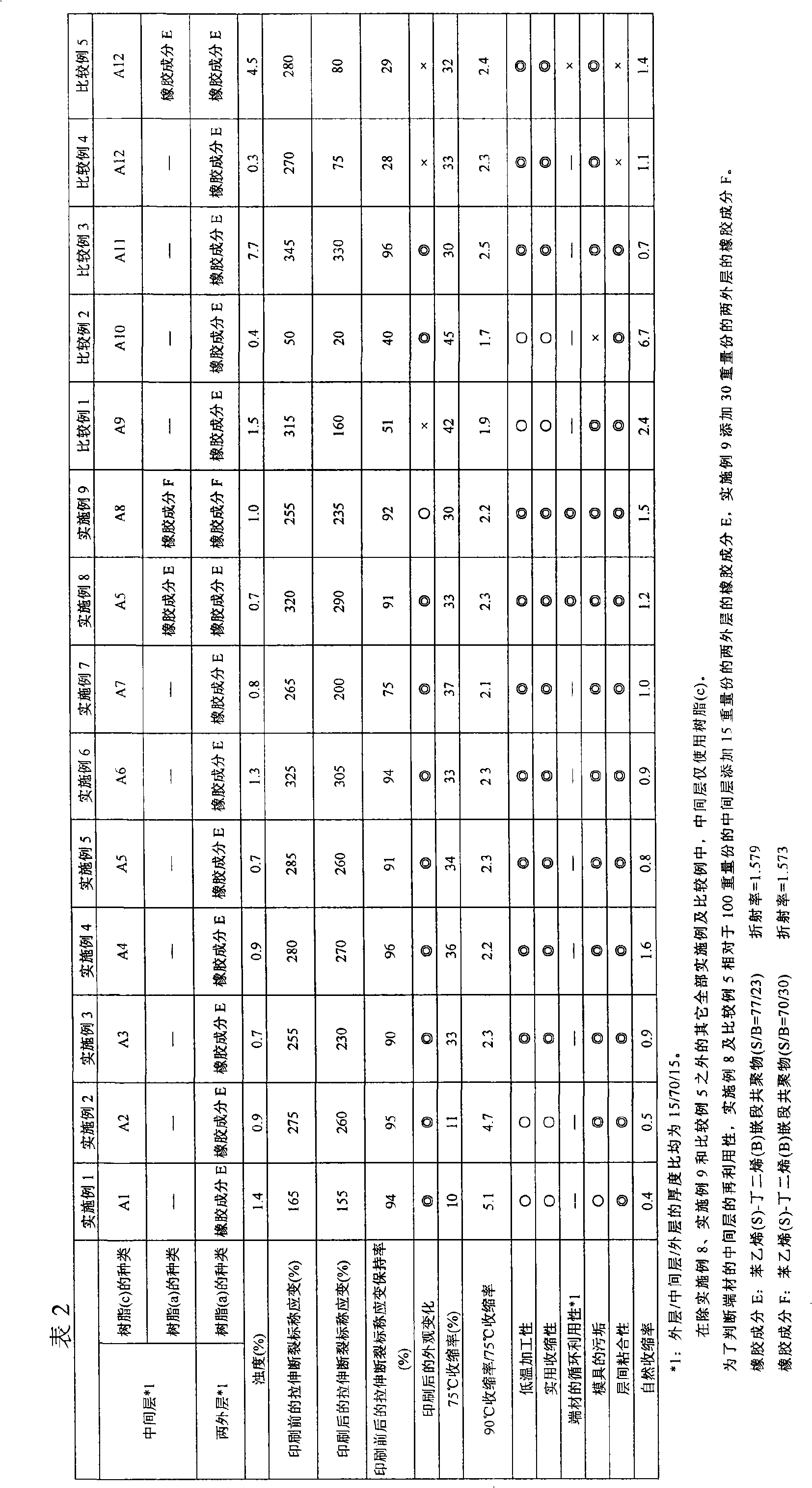

Embodiment 1~9

[0147] It can be seen from Table 2 that the multilayer film of the embodiment has little decrease in physical properties after printing, excellent printing resistance (retention rate of nominal strain at tensile fracture after printing, appearance change), and transparency, low-temperature processability, and practical shrinkage. It is also excellent in recyclability, end material recyclability and interlayer adhesion.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed is a heat shrinkable multilayer film obtained by at least uniaxially stretching a multilayer film which comprises outer layers mainly composed of a block copolymer resin (a) composed of a styrene monomer and a conjugated diene monomer, and an intermediate layer mainly composed of a resin (c) wherein a component made from a rubber elastic body (b) is contained in the form of dispersed particles in a continuous phase of a styrene polymer which is composed of a styrene monomer and an n-butyl acrylate. The rubber elastic body (b) is a block copolymer composed of 20-45% by weight of a styrene monomer and 80-55% by weight of a conjugated diene monomer, and the rubber elastic body (b) content in the resin (c) is 3-20% by weight. The resin composition of the continuous phase of the resin (c) is composed of 78-93% by weight of a styrene monomer and 22-7% by weight of an n-butyl acrylate, and the resin (c) has a Vicat softening temperature of 60-85 DEG C.

Description

technical field [0001] The present invention relates to a heat-shrinkable film suitable for use as a shrinkable label for plastic bottles and the like, which has excellent printing resistance with little decrease in physical properties after printing with oil-based ink, and also has low-temperature processability such as shrinkage, mechanical strength, practical shrinkage, and end materials. Multilayer heat-shrinkable film with excellent recyclability and interlayer adhesion. Background technique [0002] As a heat-shrinkable film for container packaging such as plastic bottles, since a rubber-like elastomer dispersed polystyrene resin is used as an intermediate layer, and a block copolymer composed of styrene hydrocarbons and conjugated diene hydrocarbons is laminated Heat-shrinkable polystyrene films obtained as front and back layers (inner and outer layers) are excellent in transparency, natural shrinkage, heat-resistant adhesion, and shrinkage finish, and therefore sever...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/30B29C55/12B29C61/06B65D23/08B65D65/40B29K105/02B29L7/00B29L9/00

CPCB29C61/003B29C61/0616B29K2009/00B32B25/08B29C55/005B32B27/08B32B27/18B32B27/22B32B27/302B32B27/308B32B27/32B32B2264/0207B32B2270/00B32B2307/30B32B2307/306B32B2307/412B32B2307/50B32B2307/516B32B2307/54B32B2307/736B32B2307/75B32B2519/00Y10T428/1328Y10T428/24942Y10T428/254Y10T428/31909

Inventor 川崎敏晴山本刚弘

Owner PS JAPAN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com