Original edition of lithographic printing plate

A technology of lithographic printing plate and original plate, applied in printing, printing process, preparation of printing surface, etc., can solve problems such as difficult adjustment of sensitivity, pollution resistance and printing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

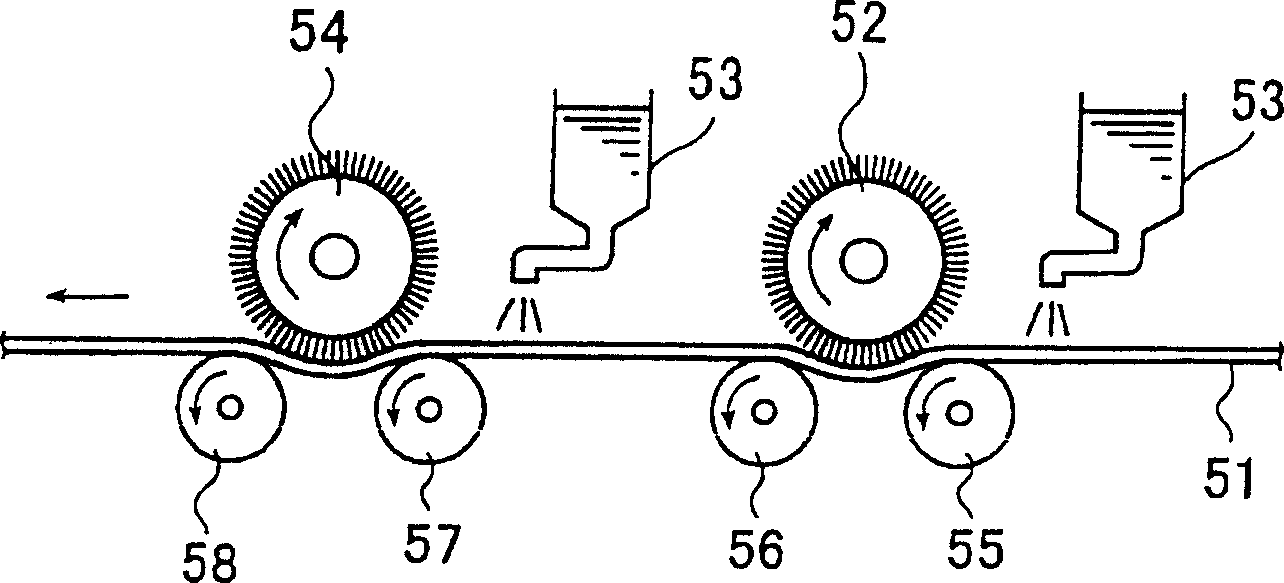

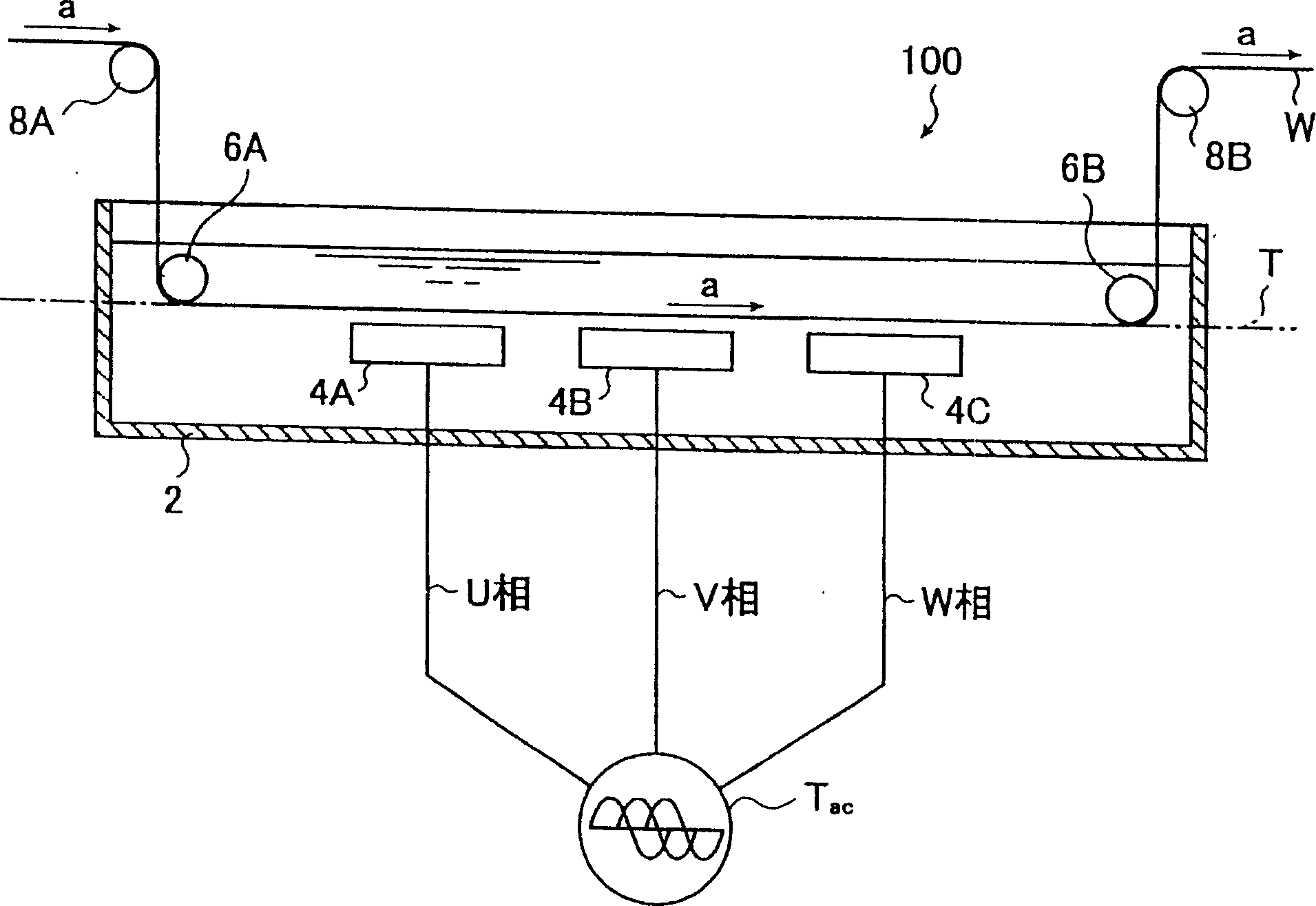

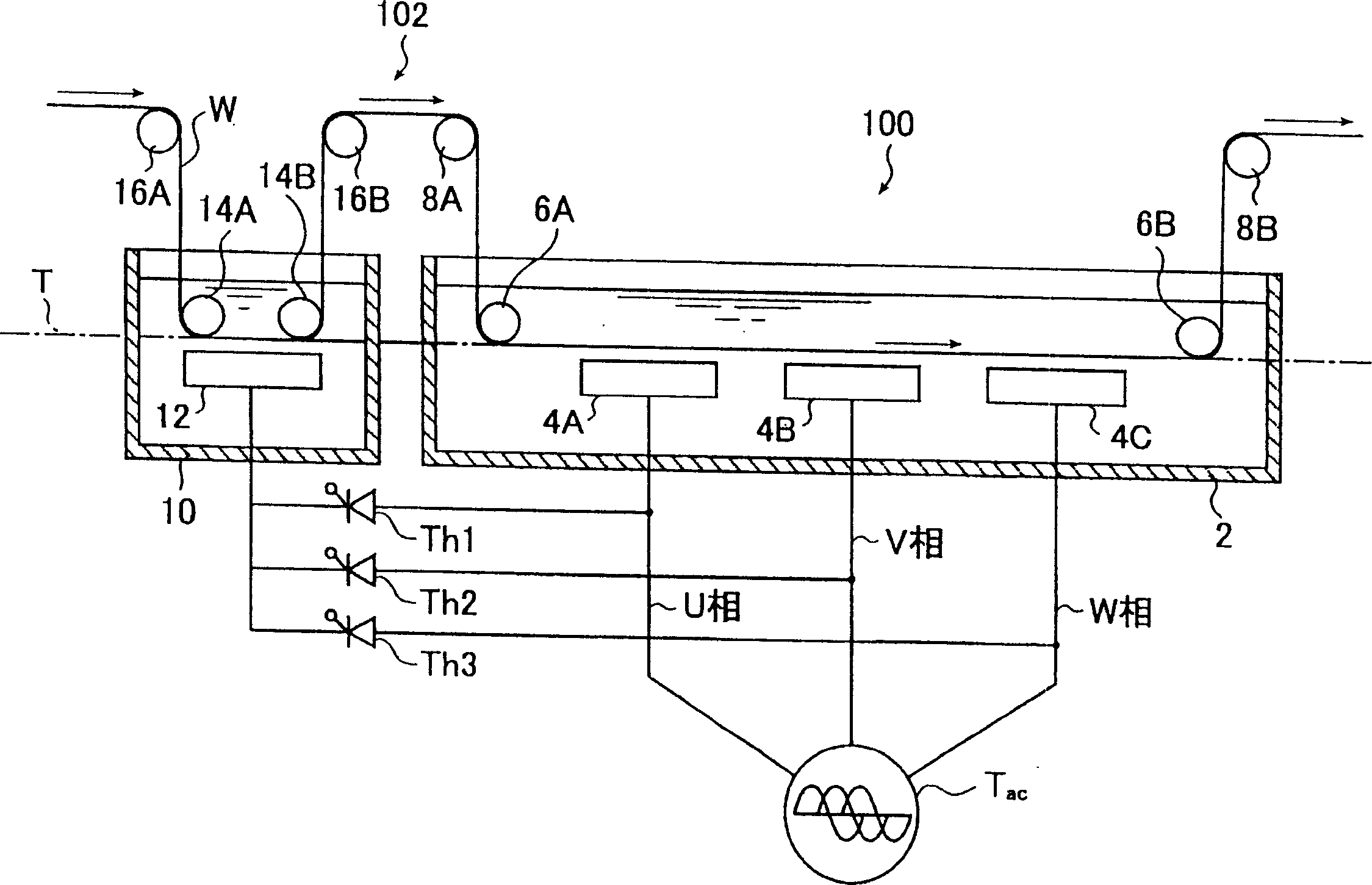

[0079] In the preparation of the support for lithographic printing plates of the present invention, it is preferable to subject the above-mentioned aluminum plate to surface treatment including electrochemical roughening treatment in an aqueous solution containing hydrochloric acid to obtain a support for lithographic printing plates. Various treatments can also be included in the treatment. In addition, in the various processes adopted in the present invention, since the alloy components of the aluminum plate used can be eluted into the treatment liquid used in the process, the treatment liquid can contain the alloy of the aluminum plate. Components, especially these alloy components are added before treatment, so that the treatment liquid is in a steady state before use.

[0080] In the present invention, although various treatment steps described later can be combined for roughening treatment, before various electrochemical roughening treatments, it is better to carry out al...

Embodiment 1-7 and comparative example 1-7

[0562] A heat-sensitive positive-type image recording layer was provided on each of the lithographic printing plate supports prepared above as follows, and the lithographic printing plate precursors of Examples 1-7 and Comparative Examples 1-7 shown in Table 1 were prepared. Before the image-recording layer is provided, an undercoat layer described later is provided.

[0563] An undercoat liquid having the following composition was coated on a lithographic printing plate support, and dried at 80° C. for 15 seconds to prepare an undercoat film. The coating amount of the coating film after drying is 15mg / m 2 .

[0564] (undercoat liquid composition)

[0565] The following polymer compounds 0.3g

[0566] Methanol 100g

[0567] water 1g

[0568] Chemical 14

[0569]

[0570]Next, a heat-sensitive layer coating liquid of the following composition was prepared, coated on a support for a lithographic printing plate provided with an undercoat layer, and the coating amount aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com