Material of lithographic printing plate, process for producing material of lithographic printing plate, and method of printing

A technology of lithographic printing plate and manufacturing method, which is applied in the preparation of printing surface, printing, printing process, etc., which can solve the problems of reduced developability, insufficient printability, increased sensitivity, etc., and achieves the effect of excellent resistance to pressure turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

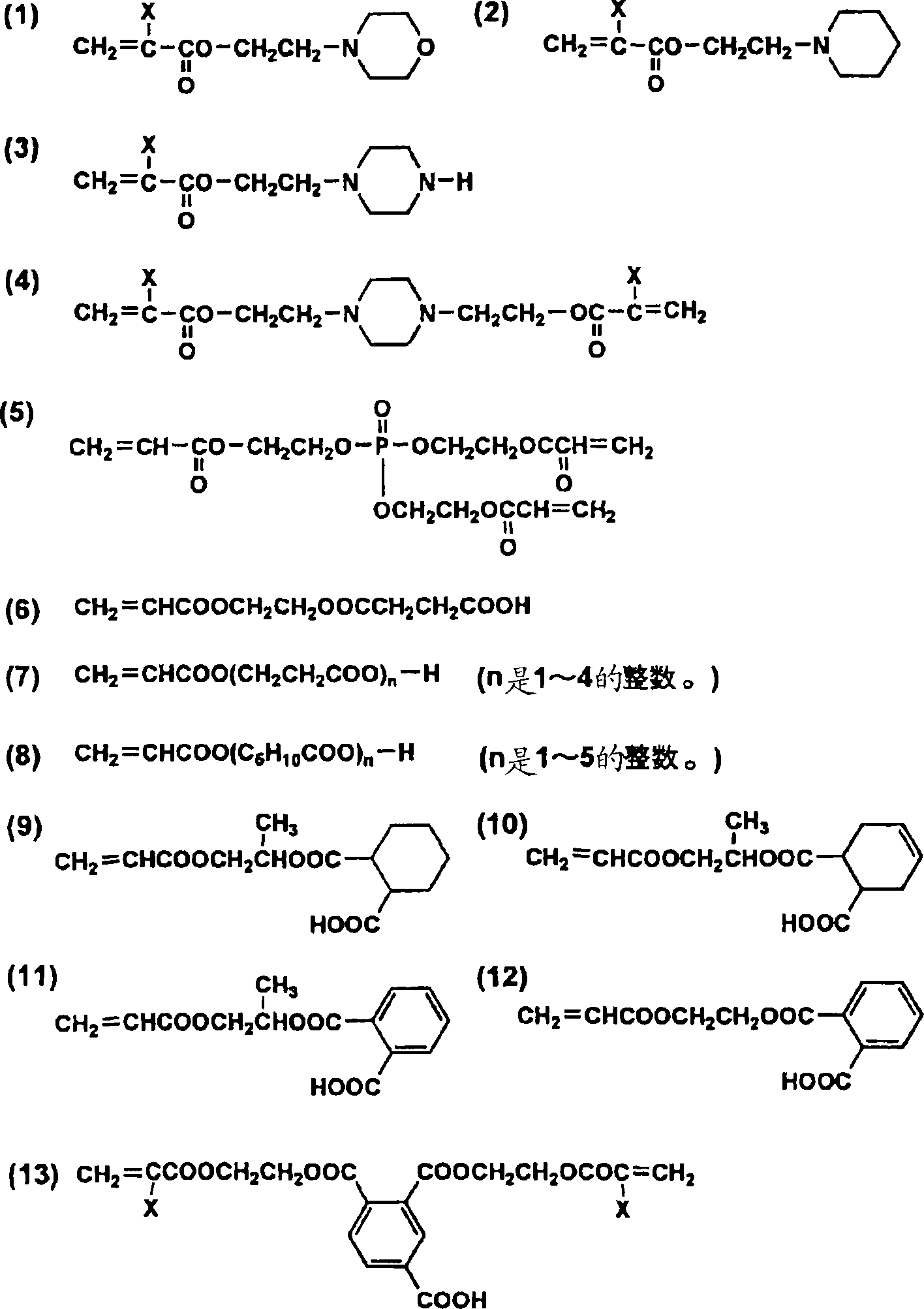

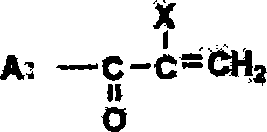

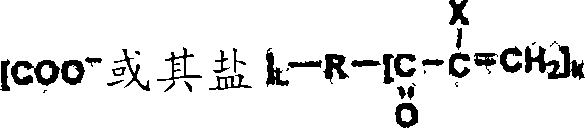

Method used

Image

Examples

Embodiment 1

[0318] (Preparation of support)

[0319] (PET resin)

[0320] To 100 parts by mass of dimethyl terephthalate and 65 parts by mass of ethylene glycol, 0.05 parts by mass of magnesium acetate hydrate was added as a transesterification catalyst, and transesterification was performed according to a conventional method. To the obtained product, 0.05 parts by mass of antimony trioxide and 0.03 parts by mass of trimethyl phosphate were added. Then, the temperature was raised slowly, the pressure was reduced, and polymerization was carried out at 280° C. and 0.5×9.8 Pa to obtain a polyethylene terephthalate (PET) resin with an intrinsic viscosity of 0.70.

[0321] Using the PET resin thus obtained, a biaxially stretched PET film was produced as follows.

[0322] (biaxially stretched PET film)

[0323] The granulated product of PET resin was vacuum-dried at 150°C for 8 hours, then, at 285°C, it was melt-extruded from a T die to form a layer, and static electricity was applied on a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com