Support for lithographic printing plate material, process for producing the same and lithographic printing plate material therefrom

A technology for lithographic printing plates and manufacturing methods, applied to the field of supports for lithographic printing plate materials and lithographic printing plate materials, capable of solving the problems of tone reproducibility, printing resistance, insufficient pollution prevention, contamination, small dot damage, etc., Achieve excellent effect of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0262] (Manufacture of supports 1 to 20)

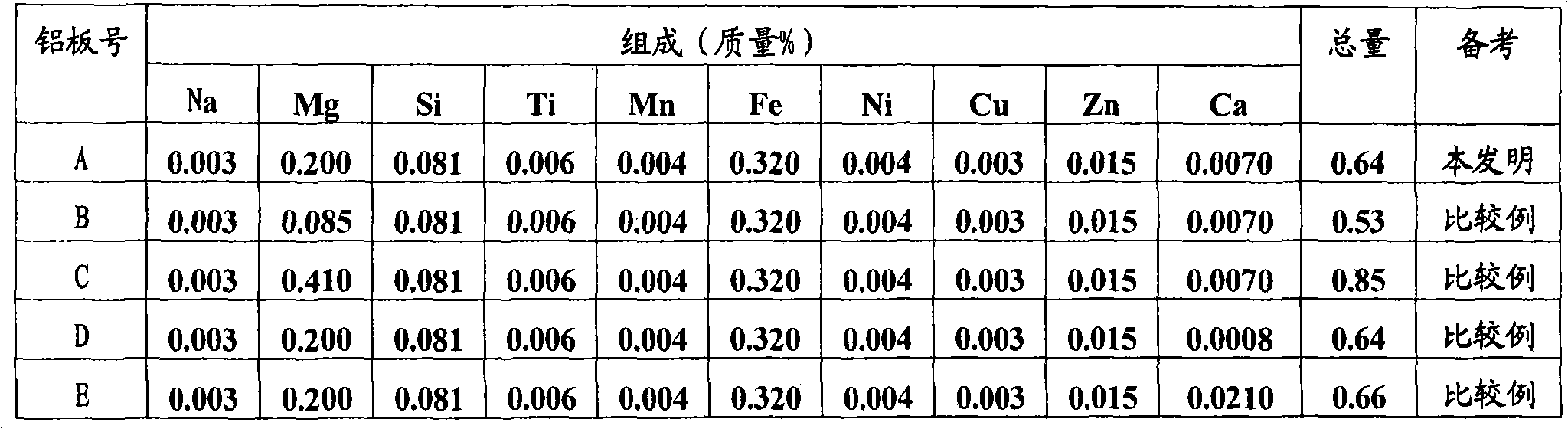

[0263] An aluminum plate with a thickness of 0.3 mm and a composition shown in Table 1 (the remainder being aluminum and unavoidable impurities) was used.

[0264] 【Table 1】

[0265]

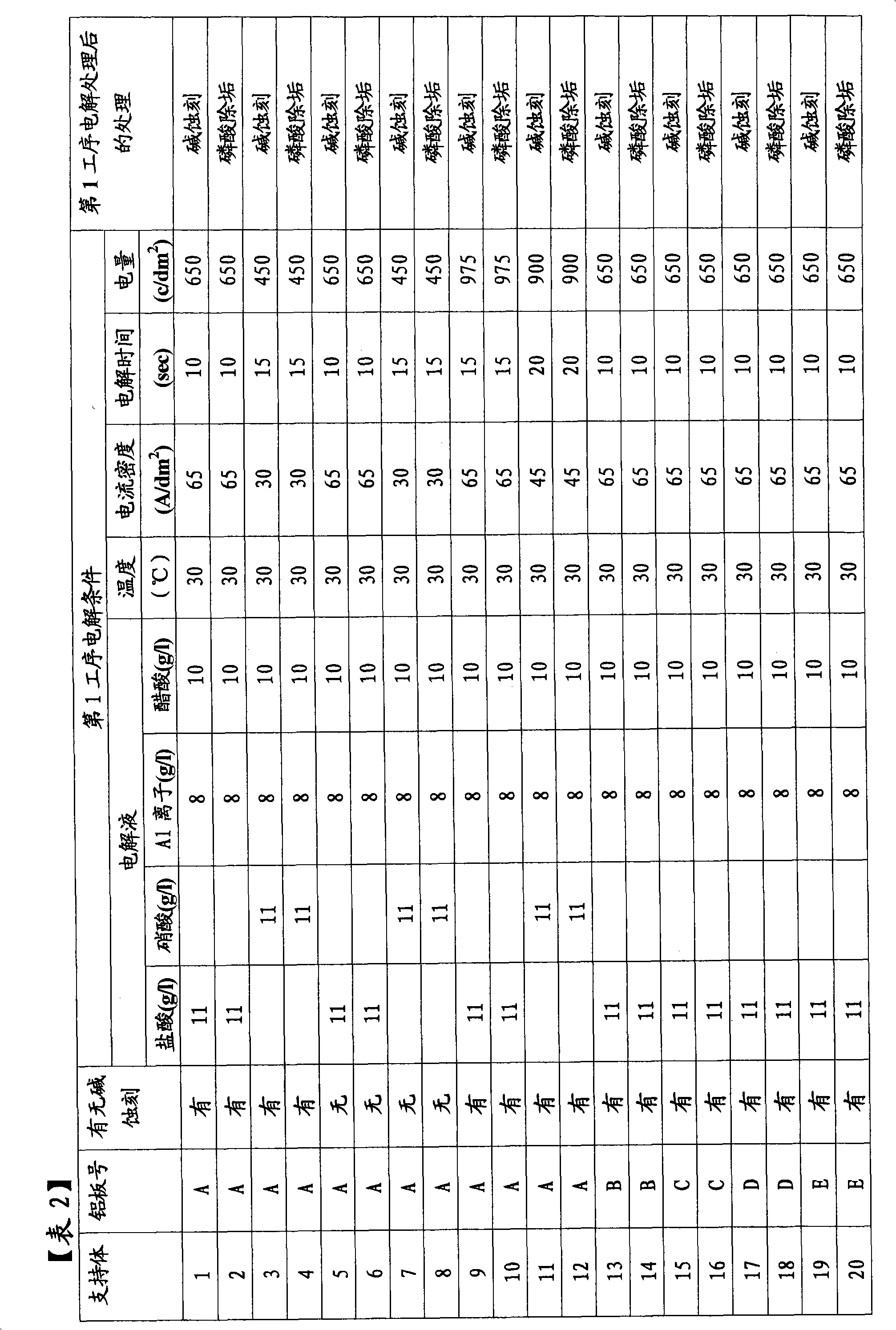

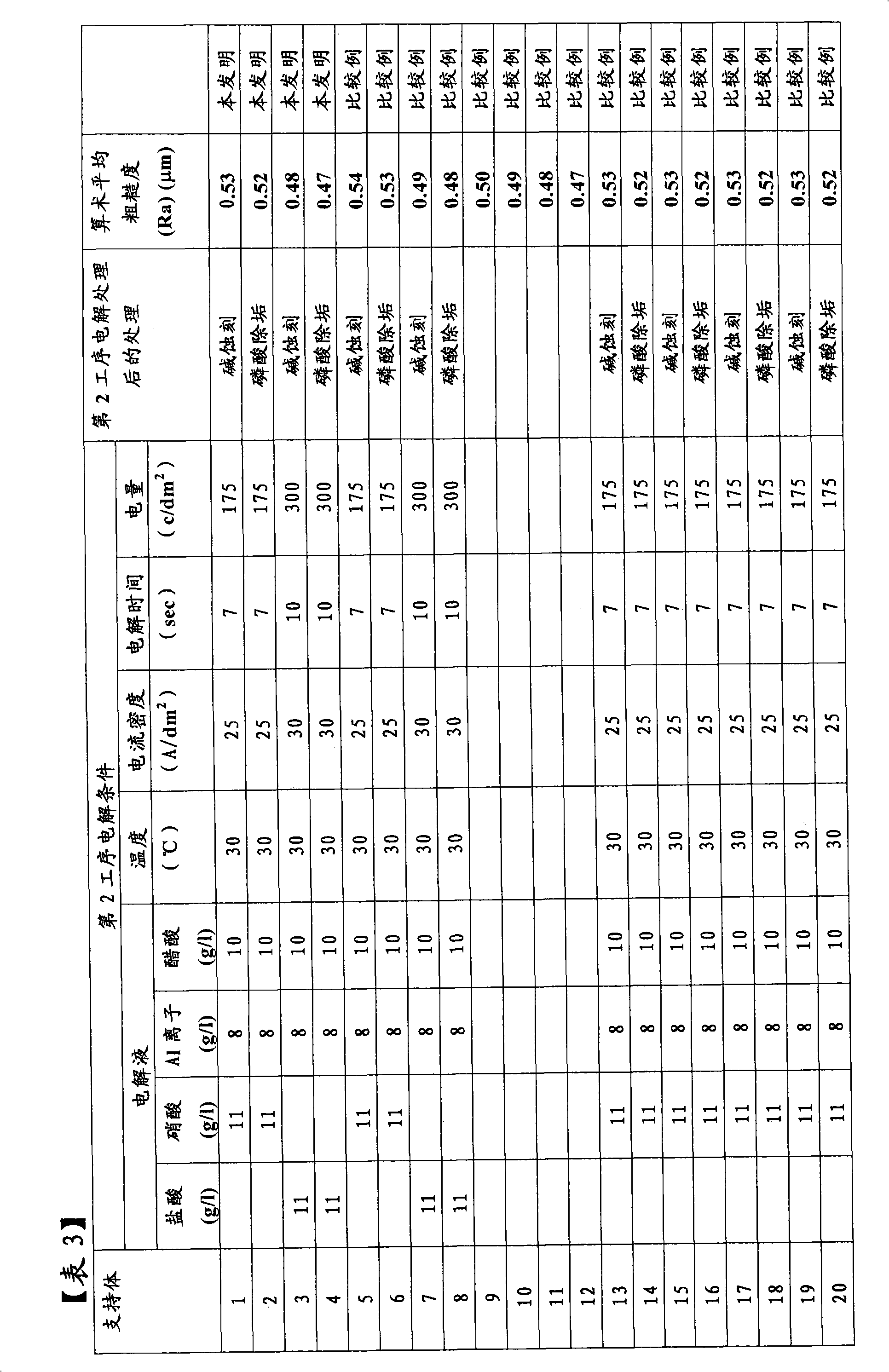

[0266] Using the conditions shown in Table 2 and Table 3, the aluminum plate was subjected to an alkali etching process, an electrolytic surface roughening process, an alkaline etching process after electrolytic surface roughening, or a phosphoric acid descaling process.

[0267] (alkali etching process)

[0268] It was dipped in a 4% sodium hydroxide aqueous solution maintained at 50° C., alkali-etched for 30 seconds, and washed with water.

[0269] The alkali-etched aluminum plate was dipped in a 5% nitric acid aqueous solution maintained at 25° C. for 10 seconds, neutralized, and washed with water. The amount of aluminum dissolved on the surface by etching is 3g / m 2 .

[0270] (Electrolytic Surface Roughening Process)

[0271] According to t...

Embodiment 2

[0330] (Manufacture of photopolymerizable lithographic printing plate materials 21-40 corresponding to ultraviolet light source)

[0331] On the above-mentioned supports 1-20, a photopolymerizable photosensitive layer coating liquid having the following composition was applied with a screen brush so that it would reach 1.9 g / m when dried. 2 , dried at 95°C for 1.5 minutes.

[0332] Then, on the photosensitive layer, the protective layer coating solution of the above composition is coated with a coater so that it becomes 1.7 g / m when dried. 2 , and dried at 75° C. for 1.5 minutes to manufacture a photopolymerizable photosensitive lithographic printing plate material with a protective layer on the photosensitive layer.

[0333] (Coating solution for photopolymerizable photosensitive layer)

[0334] Polymer binder B-1 (above) 40.0 parts

[0335] Photopolymerization initiator η-cumene-(η-cyclopentadienyl) iron hexafluorophosphate 3.0 parts

[0336] Sensitizing pigment D-3 and ...

Embodiment 3

[0357] (Manufacture of photopolymerizable lithographic printing plate materials 41-60 corresponding to infrared laser light source (830nm))

[0358] On the above-mentioned supports 1 to 20, a photopolymerizable photosensitive layer coating solution of the following composition was applied with a screen brush to make it reach 1.5 g / m when dried. 2 , dried at 95°C for 1.5 minutes.

[0359] Then, on the photosensitive layer, the protective layer coating solution of the above composition is coated with a coater so that it becomes 1.7 g / m when dried. 2 , and dried at 75° C. for 1.5 minutes to manufacture a photopolymerizable photosensitive lithographic printing plate material with a protective layer on the photosensitive layer.

[0360] (Coating solution for photosensitive layer)

[0361] Polymer binder B-1 (above) 40.0 parts

[0362] Infrared absorber D-5 (below) 2.5 parts

[0363] Benzyl N-phenylglycine 4.0 parts

[0364] Addition polymerizable ethylenically unsaturated doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com