Method for raising light guide plate screen press run and permeability

A technology of printing durability and permeability, which is applied in the production process of precision light guide plate screens, can solve the problems of inability to fully realize fineness, printing resistance, solvent resistance, leveling, stainless steel mesh hindering ultraviolet penetration, Problems such as jagged edges of graphics and texts, to achieve excellent surface smoothness, good printing permeability, and eliminate false printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

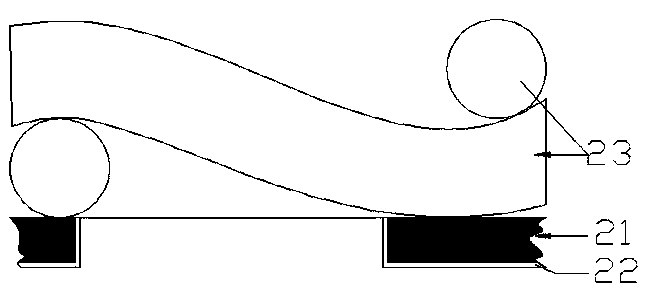

[0022] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby clearly defining the protection scope of the present invention.

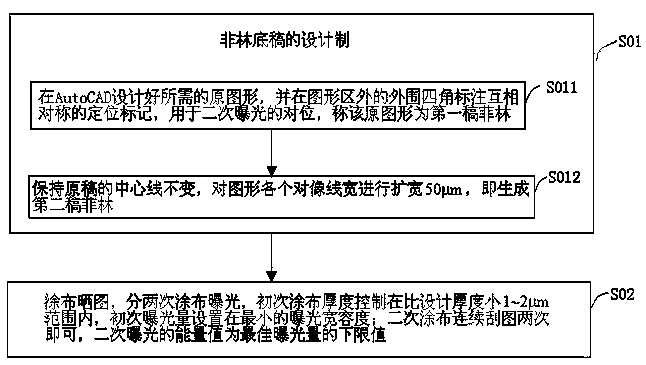

[0023] See figure 1 , the present invention provides a method for improving the printing durability and transmittance of the screen plate of the light guide plate, and completes the entire plate-making and photo-printing work by secondary coating and exposure, including the following steps:

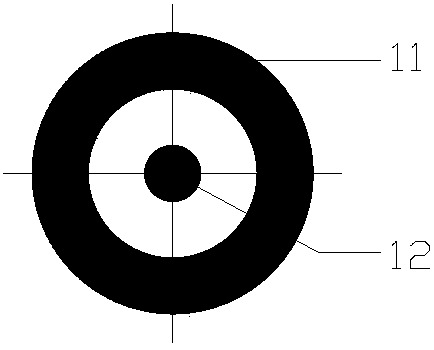

[0024] 1. For the design and production of the film draft, first use AutoCAD software to design the original graphics, and make symmetrical marks on the four corners of the graphics area, such as figure 2 As shown, the alignment mark used for the second exposure is called the first draft film; secondly, keep the center line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com