Lithographic printing plate precursor, plate making method thereof and polyvalent isocyanate compound

A lithographic printing plate and isocyanate technology, which is applied in lithographic printing equipment, printing, printing technology, etc., can solve problems such as printing stains, insufficient printing durability, and poor developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] [Preparation Method of Polymer Fine Particles]

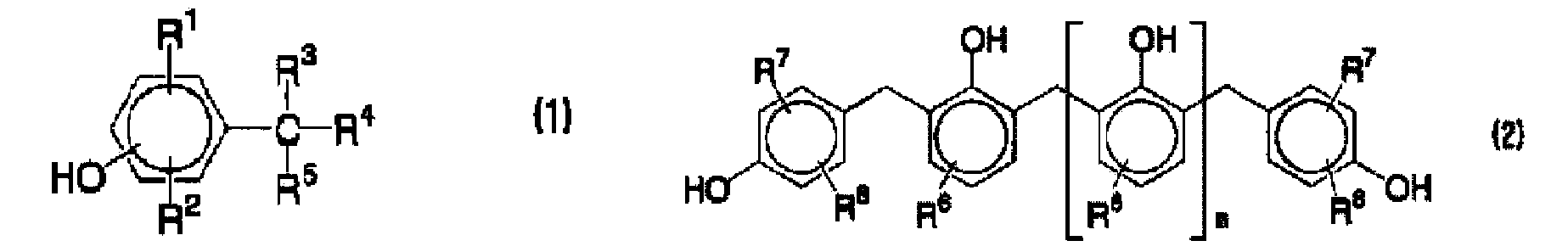

[0071] The polymer fine particle according to the present invention is composed of a polymer obtained by a reaction between an isocyanate compound and a compound having an active hydrogen atom, and the isocyanate compound includes at least the polyvalent isocyanate compound according to the present invention. Therefore, the polymer fine particles according to the present invention can increase printing durability without concomitantly reducing developability.

[0072] The polymer fine particles according to the present invention can be obtained as in Asashi Kondo, Microcapsule , The Nikkan Kogyo Shimbun, Ltd. (1970) and Tamotsu Kondo et al., Microcapsules, It was prepared in the same manner as a hitherto known method for forming microcapsules described in detail in Sankyo Publishing Co., Ltd. (1977).

[0073] Polymer fines with polyurethane / polyurea walls or polyurethane walls were synthesized by interfacial polymeriz...

Embodiment

[0251] The present invention will be described in more detail with reference to the following examples, but the invention should not be construed as being limited thereto. In the examples, unless specifically stated otherwise, with respect to polymer compounds, the molecular weight is expressed as a weight average molecular weight (Mw) and the ratio of repeating units is expressed as a mole percent.

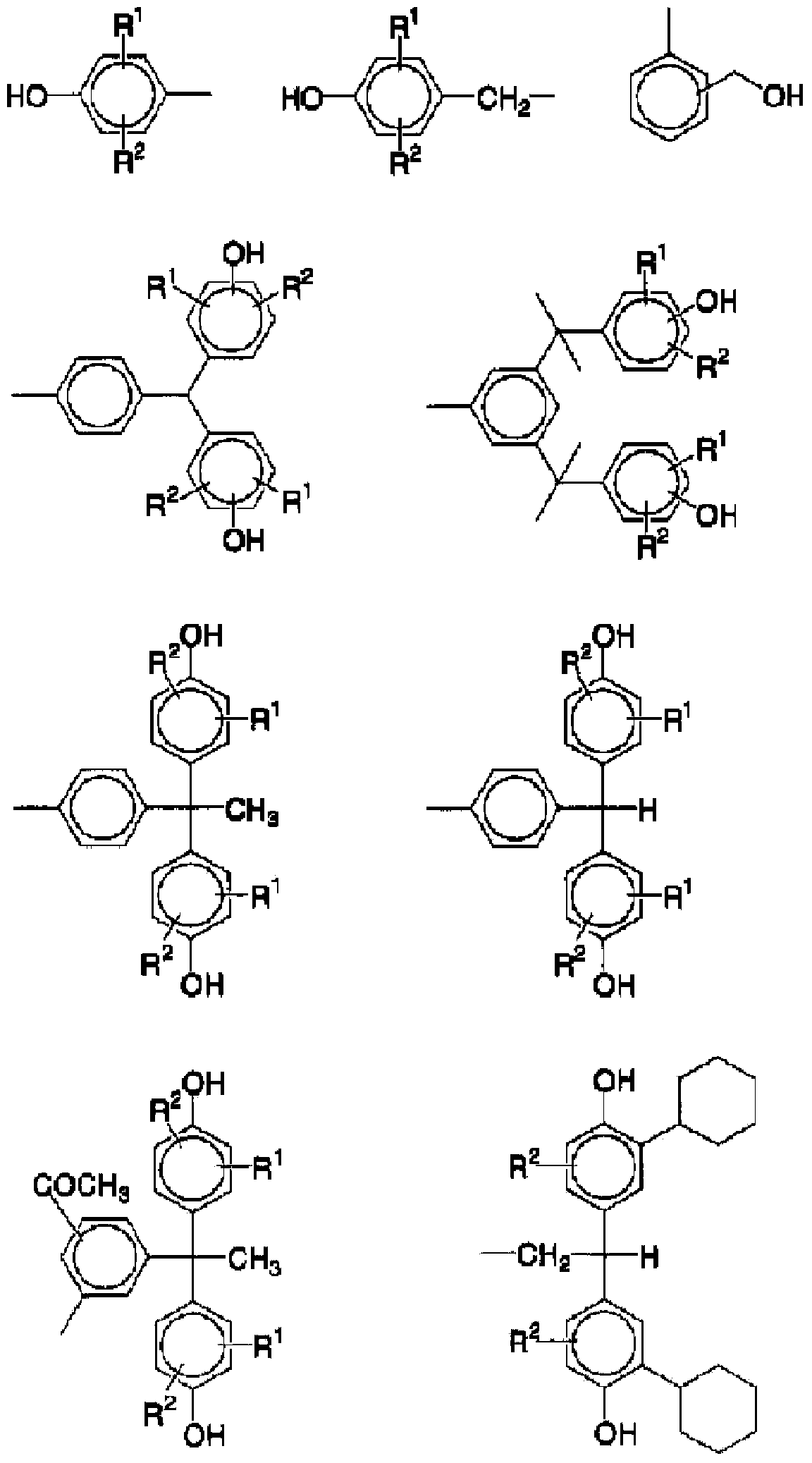

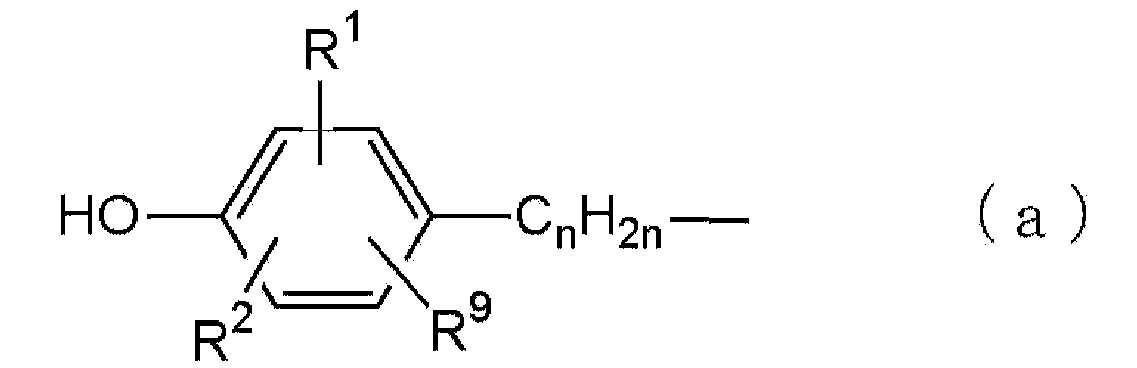

[0252] [Synthesis examples of polyvalent isocyanate adducts NCO-1 to NCO-21]

Synthetic example 1

[0253] Synthesis Example 1: Synthesis of NCO-1

[0254] In 470.7 g of ethyl acetate containing 355.6 g (1.60 mol) of isophorone diisocyanate ([PDI) and 169.6 g (0.40 mol) of polyhydric phenol compound P-2 having the structure shown below To the suspension, a solution containing 471 mg of tin octoate (STANOCT, manufactured by Yoshitomi Pharmaceutical Co., Ltd.) dissolved in 10 g of ethyl acetate was added dropwise over a period of one hour with stirring. After the dropwise addition was completed, stirring was continued for 2 hours and then stirred at 50° C. for 3 hours. Thus, a solution (concentration: 50% by weight) of polyvalent isocyanate adduct NCO-1 was obtained.

[0255] The terminal isocyanate compound obtained above was dibutyl-ureidized with dibutylamine to determine the weight average molecular weight (as calculated in polystyrene units) and its Mw was 24,400.

[0256] The obtained compound was identified by FT-IR (KBr). The data is shown below. FT-IR(KBr)3416cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Centerline average roughness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Centerline average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com