A kind of preparation method and application of double organosilicon block modified polyurethane

A technology of polyurethane and organosilicon, which is applied in the field of preparation of double organosilicon block modified polyurethane, can solve the problems of high cost, poor moisture and heat resistance, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of preparation method of double organosilicon block modified polyurethane, the steps are as follows:

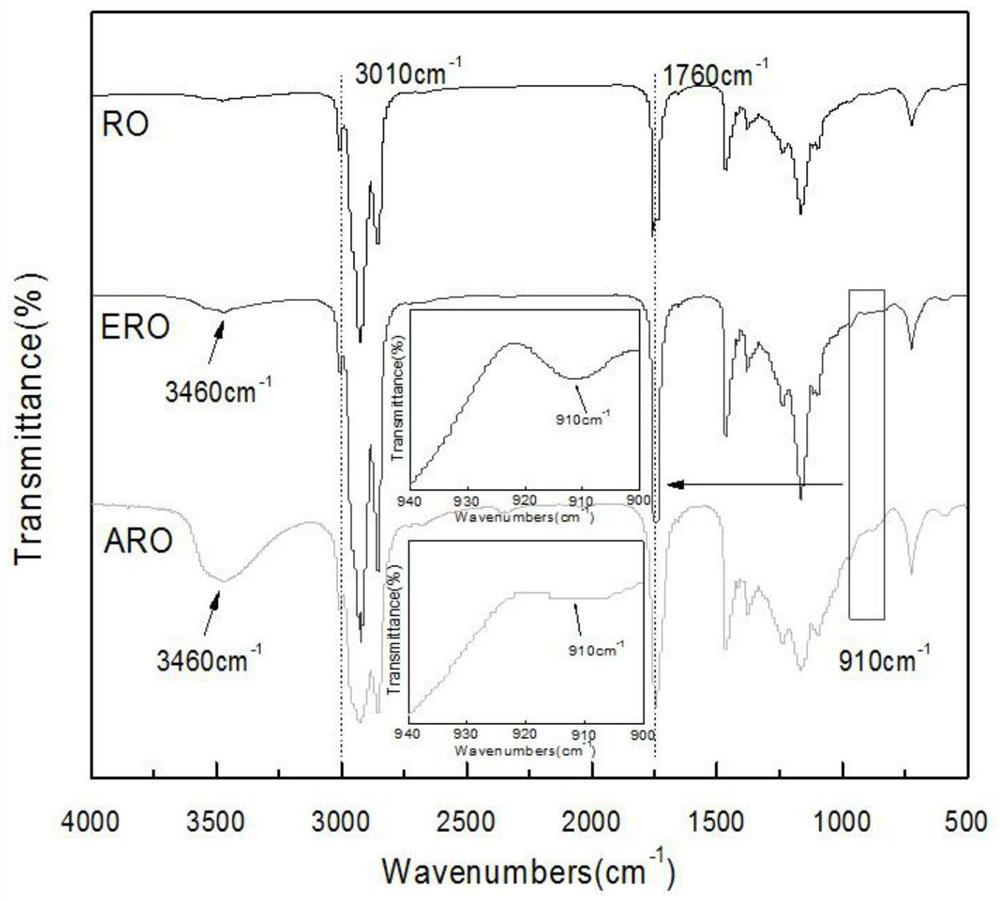

[0031] 1) Suction filtration, acid washing, water washing, alkali washing and salt washing of the waste oil in sequence, and then use activated carbon to remove water to obtain regenerated oil; mix regenerated oil, peracetic acid and sulfuric acid at a ratio of 1:0.3:0.03, Heated to 80°C for 2 hours under the protection of nitrogen, and the oil layer was neutralized to neutral with a weak base, then washed with saturated brine, and vacuum distilled to obtain epoxidized regenerated oil;

[0032] 2) Mix epoxidized regenerated oil and ethylene glycol at a ratio of 2:1, add aluminum chloride with 5% weight of regenerated oil, heat to 95°C for 2 hours under nitrogen protection, and rinse unreacted ethylene glycol with distilled water out, and vacuum distilled to obtain alcoholized regenerated oil;

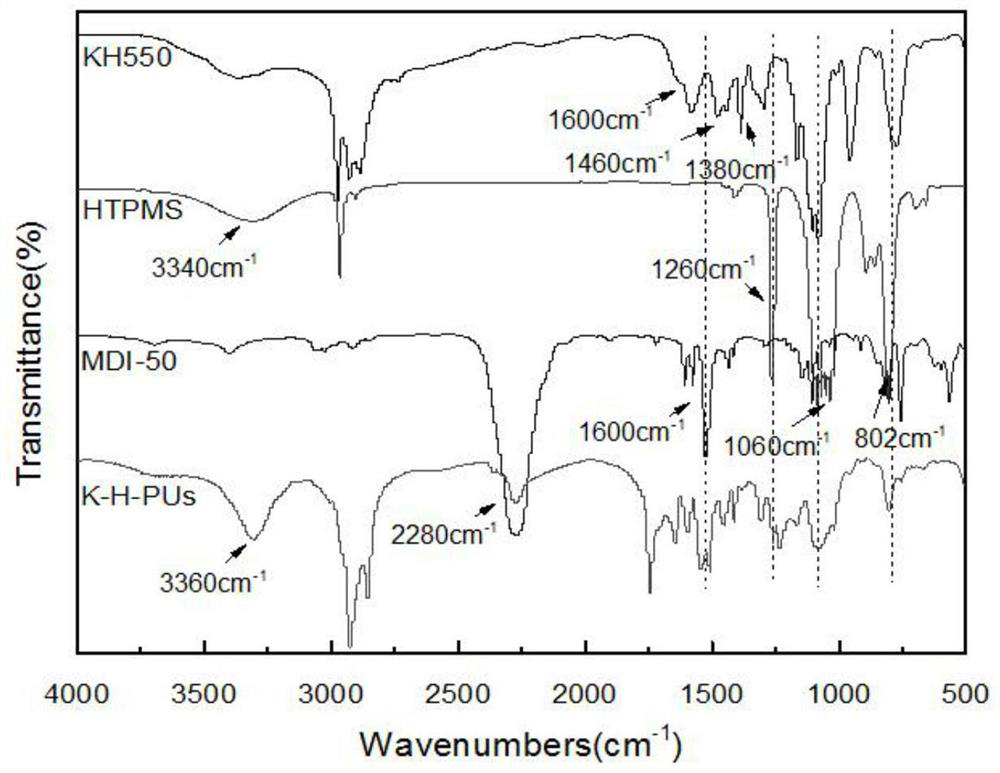

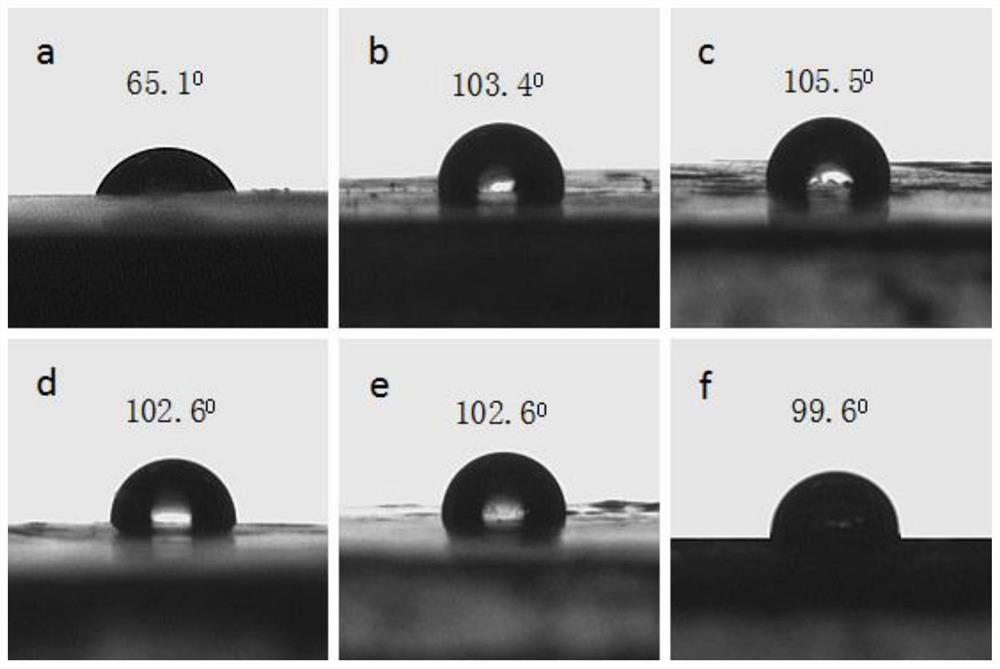

[0033] 3) Mix alcoholized regenerated oil with 20% of...

Embodiment 2

[0034] Embodiment 2: A kind of preparation method of double organosilicon block modified polyurethane, the steps are as follows:

[0035] 1) After the waste oil is suction-filtered, pickled, washed with water, alkali washed and salt washed in sequence, the regenerated oil is obtained after the water is removed with activated carbon; the regenerated oil, peracetic acid and sulfuric acid are mixed in a ratio of 1:0.2:0.02, Heated to 70°C for 3 hours under the protection of nitrogen, and the oil layer was neutralized to neutral with a weak base, then washed with saturated brine, and vacuum distilled to obtain epoxidized regenerated oil;

[0036] 2) Mix epoxidized regenerated oil and ethylene glycol at a ratio of 1:1, add aluminum chloride with 4% weight of regenerated oil, heat to 90°C for 3 hours under nitrogen protection, and rinse unreacted ethylene glycol with distilled water out, and vacuum distilled to obtain alcoholized regenerated oil;

[0037] 3) Mix alcoholized regener...

Embodiment 3

[0038] Embodiment 3: A kind of preparation method of double organosilicon block modified polyurethane, the steps are as follows:

[0039] 1) After the waste oil is suction-filtered, pickled, washed with water, alkali washed and salt washed in sequence, the regenerated oil is obtained after the water is removed with activated carbon; the regenerated oil, peracetic acid and sulfuric acid are mixed in a ratio of 1:0.4:0.04, Heating to 90°C for 1 hour under nitrogen protection, the oil layer was neutralized to neutral with a weak base, then washed with saturated brine, and vacuum distilled to obtain epoxidized regenerated oil;

[0040] 2) Mix epoxidized regenerated oil and ethylene glycol at a ratio of 3:1, add aluminum chloride with 6% weight of regenerated oil, heat to 100°C for 1 hour under nitrogen protection, and rinse unreacted ethylene glycol with distilled water out, and vacuum distilled to obtain alcoholized regenerated oil;

[0041] 3) Mix alcoholized regenerated oil wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com