Filtrate reducer and preparation method thereof

A technology of fluid loss reducer and dispersant, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of toluene toxicity, etc., and achieve the reduction of emulsion clogging, good dispersion, and reduction of instantaneous fluid loss and filtration. The effect of missing coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

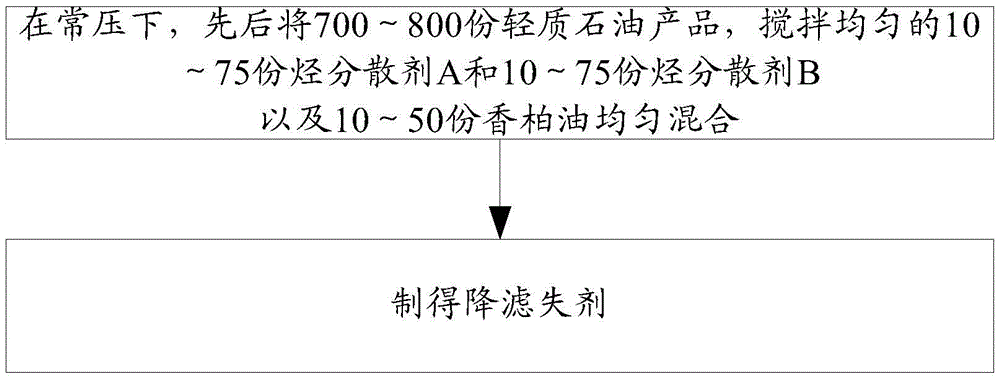

Method used

Image

Examples

Embodiment 1

[0021] 1) under normal pressure, add 700ml part of light petroleum product in 1000ml container, stand-by;

[0022] 2) Take 10ml of hydrocarbon dispersant A and 10ml of hydrocarbon dispersant B in a dry stirring bottle, mix and stir for 15min evenly;

[0023] 3) Slowly add the mixed solution of the above-mentioned hydrocarbon dispersant A and hydrocarbon dispersant B to the light petroleum product in the 1000ml container;

[0024] 4) Mix the above ingredients evenly and stir for 15 minutes;

[0025] 5) Add 10ml of cedar oil and mix evenly to obtain 730ml of fluid loss control agent.

[0026] Among them, light petroleum products are high-purity kerosene purchased from Beijing Beiqiao Borun Petrochemical Co., Ltd., by weight percentage, alkanes (C11-15) 28-48%, aromatics (C15-17) 20-50%, unsaturated Hydrocarbon (C11-14) 1-6%, cyclic hydrocarbon (C15-17) 17-44%; hydrocarbon dispersant A is a hydrophilic emulsifier (Tween-20 , chemical name is polyoxyethylene sorbitan fatty acid...

Embodiment 2

[0028] 1) under normal pressure, add 800ml part of light petroleum product in 1000ml container, stand-by;

[0029] 2) Take 75ml of hydrocarbon dispersant A and 75ml of hydrocarbon dispersant B in a dry stirring bottle, mix and stir for 15min evenly;

[0030] 3) Slowly add the mixed solution of the above-mentioned hydrocarbon dispersant A and hydrocarbon dispersant B to the light petroleum product in the 1000ml container;

[0031] 4) Mix the above ingredients evenly and stir for 15 minutes;

[0032] 5) Add 50ml of cedar oil and mix evenly to obtain 1000ml of fluid loss control agent.

Embodiment 3

[0034] 1) under normal pressure, add 700ml part of light petroleum product in 1000ml container, stand-by;

[0035] 2) Take 75ml of hydrocarbon dispersant A and 75ml of hydrocarbon dispersant B in a dry stirring bottle, mix and stir for 15min evenly;

[0036] 3) Slowly add the mixed solution of the above-mentioned hydrocarbon dispersant A and hydrocarbon dispersant B to the light petroleum product in the 1000ml container;

[0037] 4) Mix the above ingredients evenly and stir for 15 minutes;

[0038] 5) Add 50ml of cedar oil and mix evenly to obtain 900ml of fluid loss control agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com