Engraved intaglio press plate scrapping roller and preparation method

A technology for engraving gravure and wiping rollers, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of increased workload of roller makers, insufficient elasticity of the elastic layer, and low printing durability of the surface layer. The effect of reducing the workload of roll making, good elasticity and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

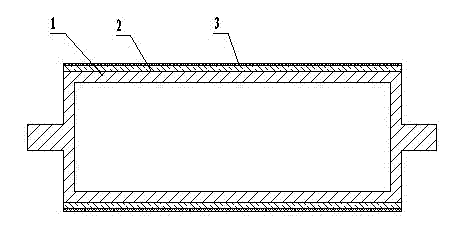

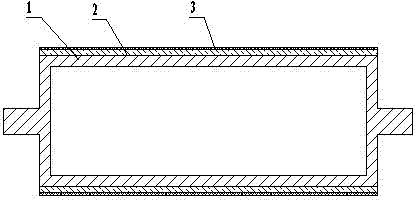

Image

Examples

Embodiment 1

[0019] The ratio of the elastic layer mixed rubber raw materials: the mass percentage of neoprene rubber is 30%, and the balance is EPDM rubber.

[0020] Ratio of surface layer raw materials (mass parts kg, the same below): PVC resin R1069 40, plasticizer dioctyl phthalate 20, crosslinking agent diallyl phthalate 2, calcium carbonate 3, coupling Agent titanate 0.2, nylon 12 0.1, stabilizer dibutyltin dilaurate 0.1, catalyst di-tert-butyl peroxide 0.1.

Embodiment 2

[0022] The ratio of the elastic layer mixed rubber raw materials: the mass percentage of neoprene is 50%, and the balance is EPDM rubber.

[0023] Raw material ratio of surface layer: PVC resin R1069 50, plasticizer dioctyl phthalate 15, crosslinking agent trimethylolpropane trimethacrylate 5, calcium carbonate 1, coupling agent titanate 0.1, Nylon 12 0.4, stabilizer dibutyltin dilaurate 0.2, catalyst di-tert-butyl peroxide 0.2.

Embodiment 3

[0025] The ratio of the elastic layer mixed rubber raw materials: the mass percentage of neoprene is 70%, and the balance is EPDM rubber.

[0026] Ratio of raw materials for surface layer: PVC resin R1069 40, PVC resin PHS-10 30, plasticizer dioctyl phthalate 40, crosslinking agent diallyl phthalate 5, trimethylolpropane trimethylene Base acrylate 5, calcium carbonate 6, coupling agent titanate 1, nylon 12 2, stabilizer dibutyltin dilaurate 2, catalyst di-tert-butyl peroxide 0.3, graphite 0.1, white carbon black 2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com