Pyramid sleeve finish machining device for metallurgical machinery winding drum part

A component and reel technology, which is applied in the field of pyramid sleeve finishing devices for reel parts of metallurgical machinery, can solve the problems of difficult processing, poor rigidity, and no position for tooling plates to achieve easy clamping and good finishing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

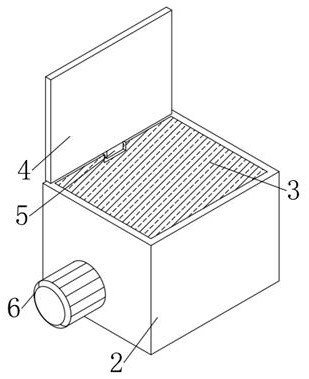

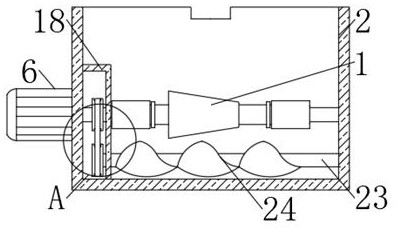

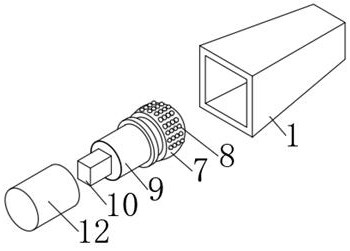

[0028] Embodiments of the present invention provide a pyramid sleeve finishing device for reel parts of metallurgical machinery, such as Figure 1-6 As shown, it comprises a quadrangular pyramid cover 1, the outside of the quadrangular pyramid cover 1 is provided with a processing box 2, the inside of the processing box 2 is provided with a deburring structure, the inside of the processing box 2 is placed with a polishing sand 3, and the processing box 2 2 The top is provided with a cover plate 4, the cover plate 4 is used to cover the polishing sand 3, to prevent the polishing sand 3 from flowing out during work, a hinged seat 5 is provided between the cover plate 4 and the processing box 2, and the processing box 2 and Cover plate 4 is rotatably connected by hinged seat 5, and one side of described treatment box 2 is provided with deceleration motor 6, and described deceleration motor 6 is fixedly connected with treatment box 2, and both sides of described quadrangular pyrami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com