Modified polyolefin resin and dispersion composition

A polyolefin resin, dispersion technology, applied in the directions of graft polymer adhesives, adhesive types, devices for coating liquids on surfaces, etc., and can solve problems such as coating or bonding of difficult polyolefin substrates , to achieve the effect of excellent water resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

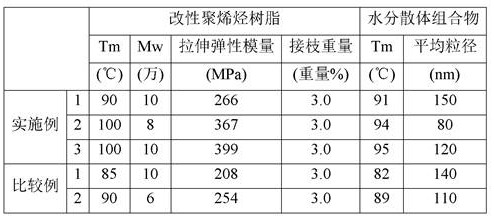

[0119] In a four-necked flask equipped with a stirrer, a cooling tube, and a dropping funnel, the propylene-1-butene copolymer (I) (the propylene component is 80 mol%, the 1-butene component is 20 mol%, Mw is 100,000, Tm is 85°C, tensile elastic modulus is 160MPa) and propylene-1-butene copolymer (II) (90 mol% of propylene component, 10 mol% of 1-butene component, Mw of 100,000, Tm 100° C., tensile modulus of 360 MPa) was heated and dissolved in 400 g of toluene at a weight ratio of 50:50 so as to make 100 parts in total. While stirring while keeping the temperature in the system at 110° C., 4.5 parts of maleic anhydride and 3.0 parts of di-tert-butyl peroxide were added dropwise over 3 hours. After further reacting for 1 hour after completion|finish of dripping, it cooled to room temperature. The reactant was poured into a large excess of acetone and purified to obtain a modified polyolefin resin (1) having a Mw of 100,000, a Tm of 90° C., and a graft weight of maleic anhydr...

Embodiment 2

[0122] Using a twin-screw extruder set at 200° C., 100 parts of propylene-1-butene copolymer (III) (90 mol % of propylene component, 10 mol % of 1-butene component, Mw of 400,000, Tm is 100° C., tensile elastic modulus is 360 MPa), 3.0 parts of maleic anhydride, and 2.0 parts of dilauroyl peroxide are mixed and reacted. Vacuum degassing was carried out in the extruder to remove remaining unreacted substances to obtain a modified polyolefin resin (2) having a Mw of 80,000, a Tm of 100° C., and a graft weight of maleic anhydride of 3.0% by weight.

[0123] In addition, using the obtained modified polyolefin resin (2), except that the addition amount of DMEA in Example 1 was set to 7 g, the aqueous dispersion composition (2) was prepared by the same method as in Example 1. . The Tm of the dried product of the aqueous dispersion composition (2) was 94°C.

Embodiment 3

[0125] Modified polyolefin resin (3) was obtained by the method similar to Example 2 except having changed the reaction temperature by the twin-screw extruder in Example 2 to 180 degreeC. The Mw of the obtained modified polyolefin resin (3) was 100,000, Tm was 100°C, and the graft weight of maleic anhydride was 3.0% by weight.

[0126] In addition, the aqueous dispersion composition was also prepared by the method similar to Example 2. The Tm of the dried product of the aqueous dispersion composition (3) was 95°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com